Introduction to Container Optimization in Maritime Ports

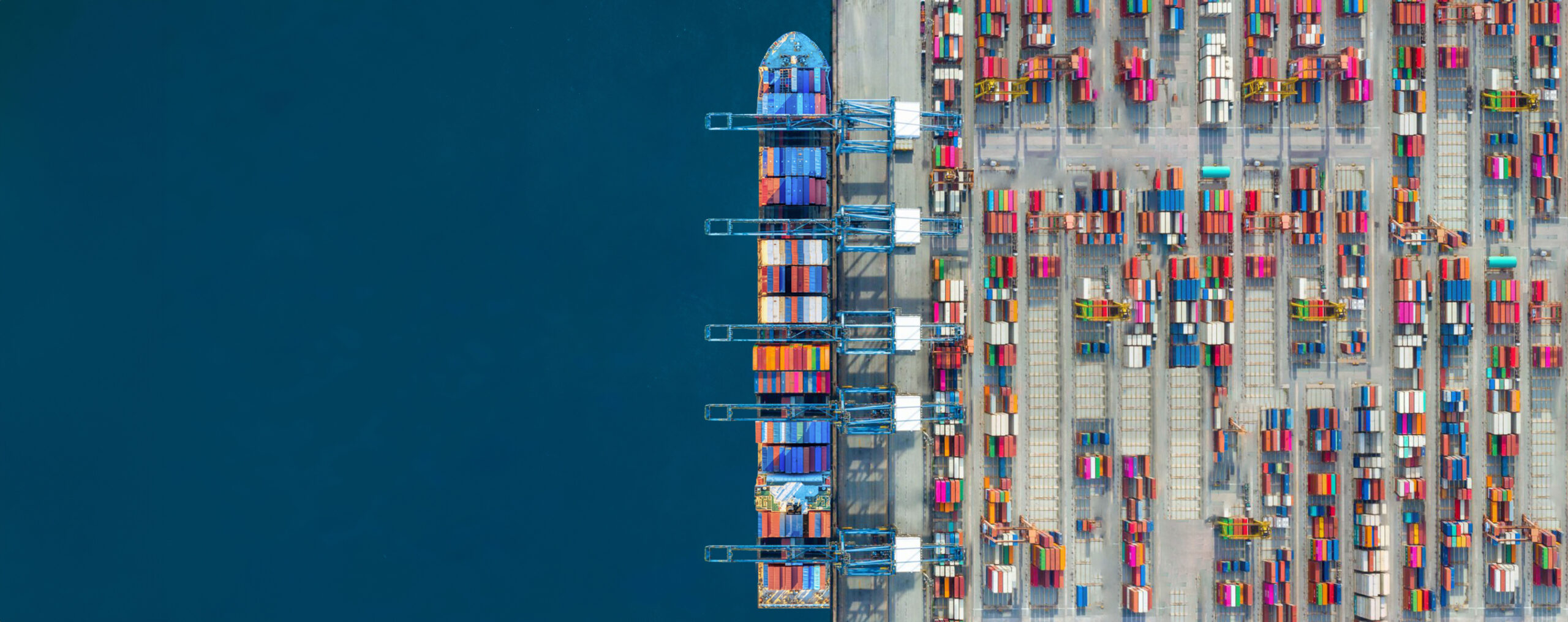

Container optimization in maritime ports is a critical aspect of modern logistics and supply chain management. This process, crucial in ensuring efficient handling and movement of goods, revolves around the strategic arrangement, storage, and transportation of containers. Maritime ports, serving as pivotal nodes in global trade networks, are constantly seeking ways to enhance the optimization of container handling. This quest is not only about managing the sheer number of containers but also involves sophisticated strategies to maximize utilization and efficiency.

The optimization of containers at ports involves several key challenges. Firstly, optimizing the stack of containers is a complex task, often likened to the container stacking problem in logistics, where the goal is to arrange containers efficiently for easy access and movement. This problem becomes more intricate considering the diverse type of container and cargo they carry. Each one container requires specific handling and storage considerations, adding layers of complexity to the optimization problem.

Moreover, ports strive to minimize delays and maximize throughput. This objective necessitates a focus on the utilization of the storage yard, ensuring that each container is placed strategically for optimal access. Advanced methods like dynamic programming and artificial intelligence are increasingly employed to find the optimal solution for container arrangement and handling. These technologies enable ports to analyze vast amounts of data, predict traffic patterns, and make informed decisions about container placement and movement.

In summary, container optimization in maritime ports is a multifaceted challenge. It requires balancing numerous factors such as the type of container, the number of containers, and the capacity of the storage yard, all while aiming for the maximum number of efficiently handled freight units. The adoption of technologies like simulation, heuristic approaches, and automation is pivotal in addressing these challenges, paving the way for more streamlined and efficient maritime port operations.

The Role of Terminals and Ports in Container Optimization

Container terminals play a vital role in the global supply chain, acting as the linchpin between sea and land transportation. The optimization at these terminals is crucial for ensuring swift and efficient handling of maritime freight. Ports, as critical junctions in this network, face the daunting task of managing an ever-increasing number of containers, necessitating the adoption of advanced optimization strategies.

A central aspect of optimization at container terminals is the efficient management of the stack. This management involves not just the physical stacking of containers but also encompasses the strategic planning of their movement and storage. Optimization efforts focus on reducing the time it takes to load and unload one container, aiming to optimize the overall operation. This process is a complex optimization problem, requiring sophisticated solutions to manage the dynamic and often unpredictable nature of port operations.

To address these challenges, ports and terminals are increasingly turning to heuristic methods and simulation techniques. Heuristic methods offer practical solutions to complex problems by simplifying decision-making processes, while simulation provides a platform to test and refine these solutions in a controlled environment. Together, these approaches enable terminals to find near-optimal solutions for managing the vast number of containers that pass through their gates daily.

Furthermore, the utilization of storage space in the yard is a critical component of container terminal optimization. Efficient space utilization not only maximizes the terminal’s capacity but also minimizes the time spent moving containers around the yard. This aspect of optimization is often addressed through dynamic programming, which helps in determining the most efficient placement of containers based on their size, type, and destination.

In conclusion, the role of container terminals and ports in supply chain optimization is indispensable. Through the application of advanced optimization techniques, including artificial intelligence, heuristic methods, and simulation, these facilities are able to enhance their operational efficiency, handle a maximum number of containers, and thus play a pivotal role in the smooth functioning of the global maritime supply chain.

Utilization Strategies for Dynamic Container Management

Dynamic container management at container yards is pivotal in enhancing the overall efficiency of maritime logistics. It focuses on optimizing each container slot to ensure that every container, whether an incoming container or an empty container, is strategically placed. This optimization reduces container relocation, thereby lowering container handling costs and improving turnaround times.

In the realm of dynamic container management, one key element is the efficient use of yard cranes. Efficient crane scheduling ensures that every container, be it a single container or a maritime container, is moved swiftly and safely. This is crucial, especially when handling container trains or engaging in container transshipment activities. Another critical aspect is optimizing container loading. It’s based on the principle of loading optimization, where each container is placed in a manner that maximizes space utilization and minimizes relocation efforts.

Container allocation within the yard blocks is a complex task. It involves planning the stacking process to ensure that containers are stacked in a way that reduces the need for future movements. The stacking policies adopted can significantly influence the overall container movement within the terminal yard. For instance, vertical stacking and proposed stacking strategies must consider factors like stack height and stacking constraints to optimize the utilization of the container yard space.

Moreover, container storage and storage space allocation are essential in managing a container terminal yard. Using data to analyze and predict the inflow and outflow of containers allows for more accurate and efficient planning. This planning, combined with multi-objective optimization techniques, aims to balance various optimization objectives, such as minimizing the stacking cost and maximizing the utilization of the container yard.

The Knapsack Problem and Heuristic Approaches in Port Optimization

The knapsack problem is a widely recognized optimization model in port container optimization. It presents a metaphor for the complex challenge of determining how to optimally stack containers within a given space. The objective function in this context is to maximize the use of available space while adhering to stacking policies and constraints.

Solving the container stacking problem, especially the container relocation problem, requires innovative approaches. Heuristic for the container stacking is frequently employed to solve the problem efficiently. These heuristics are designed to optimize container loading, ensuring that each first container placed in a stack, and every container thereafter, is positioned considering future movements and the overall container stacking index.

Moreover, port optimization also involves the careful planning of container movement among yard blocks. The planning horizon for container movement is crucial in ensuring that the beginning of the planning horizon is well-organized to prevent congestion and inefficiency later. This includes managing the container terminal yard in a way that considers different stacking heights, stack locations, and the constraints of the problem, ensuring optimal solution of the problem.

In container transshipment and intermodal container operations, attention in the literature is given to the intermodal container relocation problem. This problem requires a detailed understanding of the terminal yard’s operational dynamics, from handling operations to the derived based strategies for container storage and movement. Gantry cranes play a significant role in this, facilitating efficient handling and movement of containers, both in terms of vertical stacking and horizontal movement.

Additionally, simulation and optimization techniques are increasingly used to provide computational results that guide decision-making in container terminal operations. These techniques offer a robust framework for assessing different scenarios, helping terminal operators to anticipate challenges and adapt their strategies accordingly for optimal container transportation and supply chain optimization.

Yard Crane Scheduling and Stack Optimization

Yard crane scheduling is a cornerstone in the realm of container optimization, primarily due to its significant impact on overall port efficiency. Efficient crane scheduling ensures that every container, from a single unit to a large batch, is handled optimally, which in turn reduces waiting times and boosts throughput. The key is to synchronize the movement of yard cranes with incoming and outgoing container flows, thus minimizing idle time and enhancing the utilization of crane resources.

An important aspect of this process involves optimizing the stack where containers are placed. Efficient stack optimization demands strategic placement of containers to ensure quick access to outgoing units while keeping the storage yard orderly. This entails meticulous planning of container movements, where each container’s placement is optimized based on its destination and handling priority. Furthermore, the stacking process must be adaptable, allowing for dynamic adjustments as incoming and outgoing container volumes fluctuate.

The challenges here are multifaceted. For instance, one must consider the physical limitations of the yard, such as stack height and yard blocks, as well as operational constraints like crane reach and speed. Moreover, the variable nature of container types, sizes, and destinations adds layers of complexity to the scheduling and stacking process.

To address these challenges, ports often resort to advanced computational models and simulation tools. These tools allow for the testing and refining of various crane scheduling and stack optimization strategies in a virtual environment, enabling port operators to identify the most effective approaches before implementing them in the real world.

Multi-Objective Optimization for Cost and Efficiency in Maritime Container Operations

Multi-objective optimization in maritime container operations is an intricate balancing act between cost optimization and operational efficiency. This approach is crucial in today’s competitive maritime industry, where ports and shipping companies strive to maximize efficiency while minimizing costs. The primary objective is to optimize various aspects of container operations, such as storage, handling, and transportation, in a way that meets multiple goals simultaneously.

One of the critical areas of focus is the optimization of container storage and handling processes. This involves determining the most efficient way to store and handle containers in the terminal yard, considering factors like container type, size, destination, and handling frequency. The aim is to minimize the time and resources required for container movements, thereby reducing operational costs and improving overall efficiency.

Another key aspect of multi-objective optimization is the efficient utilization of equipment and labor. This includes optimizing the deployment of yard cranes, trucks, and other handling equipment, as well as effectively managing the workforce to ensure that operations run smoothly and efficiently. By doing so, ports can reduce idle time and labor costs, while simultaneously increasing throughput and service quality.

Additionally, maritime container operations must also consider environmental and sustainability objectives. This includes reducing emissions, minimizing waste, and optimizing fuel consumption. By integrating these environmental considerations into their optimization models, ports and shipping companies can achieve a more sustainable operation, which is increasingly important in today’s environmentally conscious market.

In practice, achieving multi-objective optimization often involves the use of sophisticated algorithms and computational models. These tools enable port operators and shipping companies to analyze various scenarios and make data-driven decisions that balance cost, efficiency, and sustainability goals. Furthermore, ongoing monitoring and adaptation are essential, as the dynamic nature of maritime operations requires continuous optimization to respond to changing conditions and requirements.

Simulation and Optimization Techniques in Container Stack Management

Simulation and optimization techniques play an increasingly pivotal role in container stack management, revolutionizing the way ports and terminals operate. These technologies allow for detailed modeling and analysis of complex logistical processes, providing invaluable insights that drive efficiency and effectiveness in handling operations.

Simulation, in particular, has become an essential tool in visualizing and understanding the intricacies of container movement within a terminal. It enables the recreation of real-world scenarios in a virtual environment, allowing terminal operators to experiment with different stacking strategies and operational workflows without disrupting actual operations. This capability is particularly valuable in testing various stacking policies and crane scheduling methods, helping to identify potential bottlenecks and inefficiencies before they impact real-world operations.

Moreover, the integration of optimization models in these simulation processes has been transformative. These models are designed to find the optimal solution for complex problems, such as determining the most efficient stacking locations or the best sequence for container movements. By combining these models with simulation, terminal operators can evaluate the effectiveness of different optimization strategies under various operational conditions.

The use of these techniques also extends to the planning and design of new terminal facilities or the expansion of existing ones. Simulation and optimization can provide critical data on how changes in layout, equipment, or processes might affect overall terminal performance, thereby guiding decision-making and investment strategies.

Advancements in Supply Chain Optimization through Container Management

The advancements in container management have significantly contributed to the evolution of supply chain optimization. In today’s global economy, efficient and reliable container handling is not just a terminal concern; it has far-reaching implications for the entire supply chain.

One major advancement has been in the area of intermodal transportation. By optimizing container movements between ships, trucks, and trains, supply chains have become more agile and responsive. This seamless integration across different modes of transportation ensures that goods move more quickly and cost-effectively from origin to destination.

Another significant development is the application of artificial intelligence and machine learning in container operations. These technologies enable more accurate forecasting of container flows, leading to better resource allocation and scheduling. They also enhance the tracking and tracing of containers, providing real-time visibility and control over the supply chain.

Moreover, the push towards digitalization in container management has led to more transparent, efficient, and sustainable supply chain operations. Digital platforms facilitate better communication and collaboration among different stakeholders, including shipping lines, port operators, and logistics providers. This integration ensures that the right information is available at the right time, leading to more informed decision-making and optimized operations.

In conclusion, the advancements in container management have been instrumental in driving supply chain optimization. By leveraging new technologies and approaches, the industry is not only improving operational efficiency but also enhancing the overall resilience and sustainability of global supply chains.

Conclusion: The Future of Maritime Container Optimization

The future of maritime container optimization is poised at an exciting juncture, where technological innovation meets operational efficiency. As we look ahead, it is evident that the continuous evolution and adoption of advanced technologies will be the driving force behind more streamlined, cost-effective, and sustainable maritime operations.

In the foreseeable future, we can expect further advancements in artificial intelligence (AI) and machine learning. These technologies will refine predictive analytics, leading to more precise forecasting of container flows and enhanced decision-making. The integration of AI will also streamline the automation of various processes within container terminals, reducing human error and increasing overall efficiency.

Another key trend will be the growing emphasis on sustainability. As environmental concerns continue to gain traction, ports and shipping companies will likely invest more in green technologies and practices. This shift could involve the adoption of eco-friendly equipment, the implementation of energy-efficient operations, and a greater focus on reducing the carbon footprint of maritime logistics.

The digital transformation of the maritime industry is another area that will continue to evolve. The use of blockchain, Internet of Things (IoT), and other digital technologies will enhance the transparency and security of maritime operations. These technologies will foster better collaboration and coordination among the various stakeholders in the supply chain, from shippers and carriers to port operators and customs officials.

Furthermore, the concept of smart ports will become more prevalent. These ports, equipped with smart technologies and data-driven insights, will be able to optimize operations dynamically, adapt to changing conditions, and provide better services to their customers.

In conclusion, the future of maritime container optimization is bright, with numerous opportunities for innovation and improvement. As the industry continues to embrace new technologies and approaches, we can expect to see more efficient, cost-effective, and sustainable maritime operations. The journey towards this future is an ongoing process, and it will be fascinating to watch the transformations that lie ahead in this dynamic and vital sector.

FAQ: Your Guide to Understanding Container Terminal Stack Optimization

Dive into the world of container terminal stack optimization with our comprehensive FAQ. Here, we answer the most pressing questions about this crucial aspect of maritime logistics, providing insights into strategies, challenges, and the impact of technology. Explore these answers to gain a clearer understanding of how container terminal efficiency is enhanced through effective stack optimization.