Introduction to Maritime Container Terminals

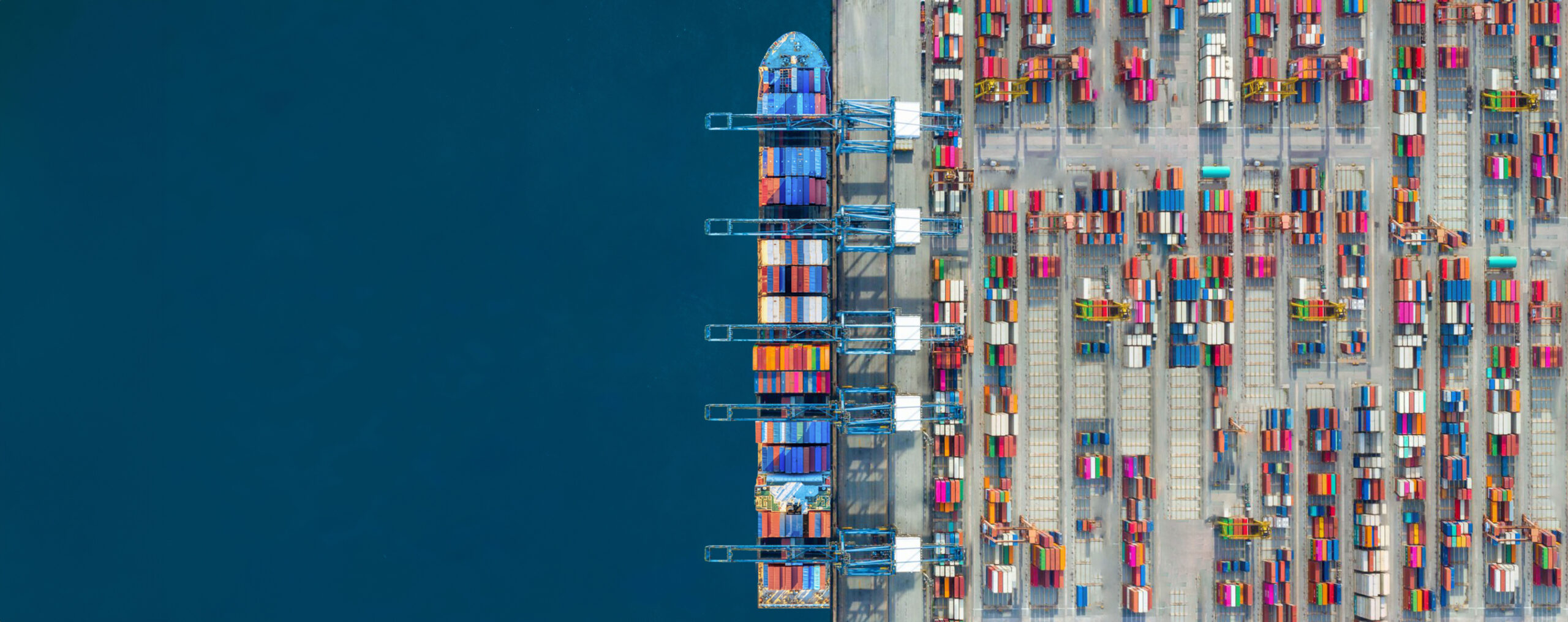

Maritime container terminals play a pivotal role in global trade, acting as hubs for the movement and storage of goods. The optimization of container terminals is crucial in enhancing the efficiency and throughput of maritime logistics. Key elements in this process include the effective handling of containers and the strategic allocation of resources such as berth space, cranes, and yard storage. Simulation models are often used to analyze and improve terminal operations, focusing on the optimal use of space and equipment. These simulations help in decision-making, particularly in optimizing the layout of the terminal yard and the scheduling of quay cranes.

Container stacking strategies in the storage yard are central to terminal efficiency. The allocation of storage space for import, export, and transshipment containers needs to be computed meticulously to minimize delays and maximize throughput. Yard planning, an integral part of terminal operations, involves determining the optimal yard block and crane deployment strategies to handle the expected number of containers. This planning is often supported by sophisticated optimization models and decision support systems.

Moreover, the operations research community actively contributes to this field through literature reviews, international conferences, and research directions. They provide heuristic approaches and optimization algorithms that aid in improving the overall terminal performance. In summary, maritime container terminals require a meticulous approach to optimization, balancing the need for space allocation, equipment utilization, and operational efficiency.

Optimizing Container Stacking in Maritime Transport

Optimizing container stacking within maritime transport is a critical aspect of efficient terminal operations. The approach to container stacking directly impacts the allocation and use of yard space, affecting overall terminal capacity and efficiency. Rule-based dynamic container stacking has emerged as an innovative strategy in this area, allowing for more flexible and efficient handling of containers. This method involves creating a dynamic environment where container slot allocation can adjust to changing conditions, such as the arrival of import and export containers.

In container terminals, the optimal yard layout and container slot allocation are crucial. These decisions affect the ease of access to containers, the speed of loading and unloading operations, and the overall flow of goods through the terminal. Yard template planning and the use of an optimization algorithm are essential tools in achieving optimal yard utilization. They help in effectively managing container inventories in port container terminals, thereby enhancing the efficiency of storage yard management.

Furthermore, integrated container logistics and transportation review play a significant role in optimizing operations in container terminals. They provide insights into the latest trends and technologies in yard allocation, container transshipment, and container relocation. Efficient management in container terminals requires a comprehensive understanding of terminal operating systems, handling operations, and space allocation strategies.

The research in maritime transport research is continuously evolving, providing new optimization policies and models for optimizing import and export yards. These advancements not only optimize the yard but also contribute to improving the overall terminal system, including yard equipment and container weight handling. In conclusion, optimizing container stacking in maritime transport requires a multifaceted approach that encompasses various aspects of terminal operations, from yard planning to the adoption of advanced optimization techniques.

Container Terminal Operation: The Role of Simulation and Optimization

In the realm of container terminal operation, the interplay of simulation and optimization models plays a crucial role. These models offer terminal operators a comprehensive toolkit to refine and enhance the efficiency of port terminals. Specifically, simulation models provide a detailed representation of terminal operations, allowing for the analysis and improvement of processes such as container handling, yard crane deployment, and quay crane scheduling. This simulation is vital in understanding the complex dynamics of maritime container terminals and identifying bottlenecks that can impede operations.

Optimization in container terminals is not just about enhancing the speed of operations; it also involves a strategic approach to allocate resources and manage container traffic. Optimization algorithms and discrete event simulation models are instrumental in determining the optimal allocation of containers, whether in storage yards or for loading operations. These models compute the most efficient ways to utilize space, handle container shipping, and manage the number of containers, ultimately aiming to minimize delays and maximize throughput.

Furthermore, the use of a decision support system in terminal operating systems helps to integrate various aspects of terminal operations, including storage space allocation and yard planning. These systems aid terminal operators in making informed decisions about yard capacity, container slot allocation, and the overall layout of the terminal. This integrated approach to container terminal optimization, supported by operations research and logistics and transportation review, ensures that the terminals operate at peak efficiency, contributing significantly to the smooth functioning of global maritime transport.

Yard Operations: The Heart of Maritime Container Terminals

Yard operations form the backbone of maritime container terminals, where the primary focus is on optimizing the use of space and equipment to improve terminal performance. This optimization entails a comprehensive approach to yard planning, including the allocation of yard blocks and the efficient deployment of yard cranes. The goal is to optimize the yard, ensuring that containers are stacked and managed effectively to facilitate quick and easy access for loading and unloading operations.

A significant aspect of yard operations is the management of container inventories in port container terminals. This involves the strategic allocation of storage space for import and export containers and the efficient handling of container relocation and transshipment processes. The application of optimization models and algorithms in yard planning enables terminal operators to maximize yard capacity, ensuring that the terminal yard is used optimally.

Moreover, the optimization approach in yard operations extends to the selection and use of yard equipment. The terminal operating system must effectively allocate yard side resources, including yard cranes and storage space, to handle the container weight and volume efficiently. This process often involves the use of heuristic methods and simulation models to predict and plan for varying levels of container traffic.

In addition to operational efficiency, yard operations also focus on areas of the terminal that require specific attention, such as storage yard management and space allocation. Integrated container management systems and optimization policies aid in streamlining these processes, contributing to the overall efficiency in container terminals. Ultimately, effective yard operations ensure that maritime container terminals maintain high levels of terminal performance, playing a crucial role in the global logistics and transportation network.

Rule-Based Dynamic Container Stacking: A Game Changer in Port Terminals

Rule-based dynamic container stacking is revolutionizing container terminal operations. This innovative approach optimizes the stacking of containers in the yard, factoring in variables such as import and export schedules, container weight, and type. By employing a set of predefined rules, this method dynamically allocates containers to specific slots in the yard, significantly enhancing efficiency in container terminals. This system, often supported by advanced optimization models and simulation tools, allows for real-time adjustment in yard allocation, adapting to changing conditions in the terminal.

The integration of rule-based dynamic container stacking with the terminal operating system ensures optimal yard capacity utilization. It minimizes the time spent relocating containers, thereby speeding up loading and unloading operations. This method also improves the allocation of yard side resources, including yard cranes and storage space, effectively managing yard storage and yard crane deployment. By optimizing container slot allocation and minimizing unnecessary container movement, maritime container terminals can achieve optimal operational flow and enhance terminal performance.

Moreover, this approach contributes significantly to the overall optimization of port terminals. It allows terminal operators to handle a higher number of containers efficiently, thereby improving the terminal yard’s throughput. Implementing rule-based dynamic container stacking is a critical step towards achieving optimization in container terminal operation, setting new standards for efficiency and effectiveness in maritime logistics.

Yard Planning and Optimization: Balancing Efficiency and Flexibility

Yard planning and optimization in maritime container terminals involve a strategic approach to effectively utilize the available space and resources. This process requires a careful balance between operational efficiency and the flexibility to adapt to changing conditions in maritime transport. Optimization in yard planning focuses on determining the optimal arrangement of yard blocks, allocation of storage space, and deployment of yard equipment, including yard cranes. These decisions are critical in managing the storage yard effectively, ensuring that containers are stacked and accessed in the most efficient manner.

The use of optimization algorithms and simulation models plays a vital role in yard planning. These tools help compute the best strategies for container handling, including the allocation of containers in import and export yards, and optimizing yard crane scheduling. They also assist in managing multiple yard operations simultaneously, enhancing the overall efficiency of container terminal yard operations.

Furthermore, yard planning also involves the development of a robust decision support system, integrating operations research findings and logistics and transportation reviews. This system guides terminal operators in making informed decisions about yard capacity, space allocation, and container relocation. By optimizing these aspects, maritime container terminals can minimize operational delays and maximize throughput, contributing to improved terminal performance.

In summary, yard planning and optimization are essential in ensuring the smooth functioning of operations in container terminals. This process not only optimizes the yard side of operations but also plays a crucial role in enhancing the efficiency and effectiveness of the entire terminal system.

Operations Research in Container Terminal Optimization

Operations research in container terminal optimization is a multidisciplinary field that employs advanced mathematical models and algorithms to enhance terminal efficiency. This field focuses on optimizing various aspects of container terminal operations, including container handling, yard operations, and resource allocation. Key areas of focus include the development of optimization models for quay crane scheduling, yard crane deployment, and container stacking strategies. These models aim to minimize operational delays and maximize terminal throughput.

The use of operations research in maritime container terminals extends beyond mere operational efficiency. It also includes the strategic planning of terminal layout, storage yard management, and decision-making regarding terminal equipment investments. By utilizing discrete event simulation and heuristic algorithms, terminal operators can predict and plan for various operational scenarios, ensuring optimal resource utilization.

Furthermore, operations research contributes to the development of decision support systems that aid terminal operators in real-time decision-making. This integration of research findings with practical terminal operations helps in adapting to the dynamic nature of maritime transport, ensuring that container terminals remain competitive and efficient in the rapidly evolving global trade landscape.

Conclusion: The Future of Container Terminal Efficiency

The future of container terminal efficiency lies in the continuous advancement of optimization techniques and the integration of cutting-edge technology. The ongoing research and development in operations research, coupled with innovations in terminal operating systems and simulation models, are set to further streamline container terminal operations. As maritime transport continues to grow, the demand for more efficient and sustainable terminal operations will drive the evolution of optimization strategies.

In the coming years, we can expect to see more sophisticated decision support systems, enhanced use of artificial intelligence in terminal operations, and greater emphasis on sustainability and environmental considerations. These advancements will not only improve operational efficiency but also contribute to the broader goals of reducing the environmental impact of maritime logistics.

Overall, the pursuit of efficiency in container terminals remains a dynamic and evolving field, with new challenges and opportunities emerging as global trade patterns shift. The continued focus on optimization and technology adoption will be key to meeting these challenges and ensuring the ongoing success of maritime container terminals in the global economy.

FAQ: Insights into Container Yard Optimization

Discover the most frequently asked questions about container yard optimization, a crucial aspect of maritime logistics. This section provides clear, concise answers to common queries, offering valuable insights into the strategies, technologies, and challenges involved in optimizing container yard operations. Whether you’re a logistics professional or simply curious, these FAQs shed light on the intricacies of efficient container handling and management.