Introduction to container terminal and port networks

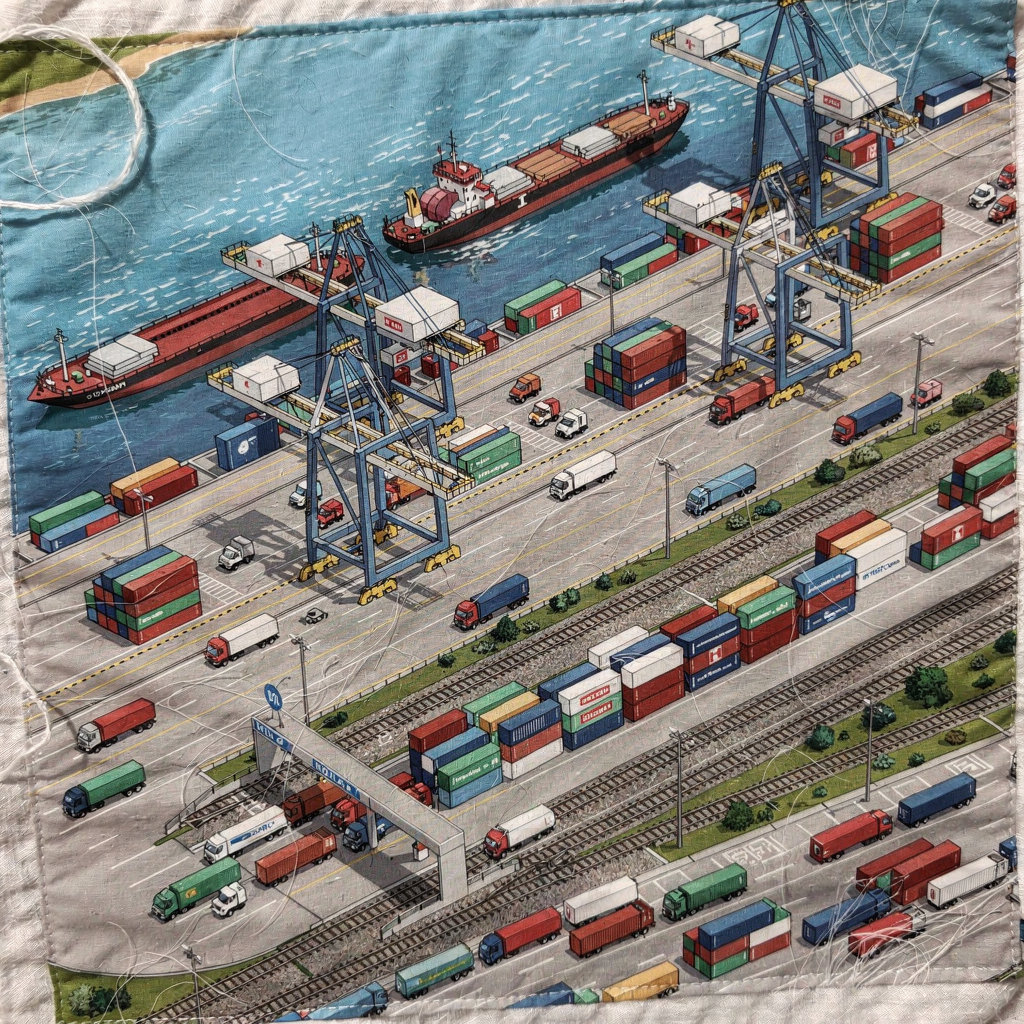

Inland container terminals act as the connective tissue between seaports and hinterland transport. They move IMPORT AND EXPORT boxes between ships, trucks, trains, and barges. In effect, they extend the port to the hinterland so goods reach customers faster. Importantly, inland hubs often handle a substantial share of total flows. For instance, major logistics corridors see inland terminals managing roughly 30–40% of twenty-foot equivalent units. This statistic shapes planning and investment priorities across the supply chain.

Terminal managers must balance quay productivity, yard space, and gate throughput. Therefore, using virtual environments to test changes reduces risk. Discrete event approaches let planners replay vessel calls, truck peaks, and rail windows. For example, researchers show DES helps reproduce container import, export, and transshipment patterns in realistic detail (container terminal digital twin modeling). As a result, teams can experiment without disrupting current operational activities.

Simulation supports port connectivity and intermodal links. It models multimodal handoffs and road networks that feed the yard. Also, it clarifies how delays cascade from the seaport to inland consolidation centers. In practice, improving these links reduces container dwell and operational costs. The ability to trial scheduling rules, resource mixes, and layout changes gives port managers a clear path to improve the operational metrics that matter.

Loadmaster.ai uses digital twin sandboxes to train policies with reinforcement learning. Thus, the company lets terminals generate experience safely. The approach avoids dependence on historical records alone. Next, planners can compare scenarios and decide with confidence. Finally, this approach turns firefighting into proactive planning.

Building a discrete event simulation model for terminal operation

Discrete event simulation forms the backbone of most terminal simulation. In a DES model, events such as crane lifts, truck arrivals, and gate checks drive state changes. The method represents stochastic arrival patterns and random service times. It therefore captures variability that deterministic tools miss. Practitioners use DES to model container IMPORT AND EXPORT, transshipment flows, and yard stacking dynamics (digital twin and DES).

Key elements include representation of quay operations, the container yard, and intermodal interfaces. Model inputs list arrival rates, service times, handling durations, and shift patterns. Also required are gate schedules, rail windows, and the number of containers per call. The simulation model developed must reflect crane cycles, yard truck loops, and storage policies. Then the model can evaluate queuing at the gate and congestion in the container yard.

Resource management is central. The simulation captures crane assignments, yard truck routes, and the distribution of handling equipment. It models crane dwell, yard stacking depth, and container stacking rules. In this way, the DES helps terminal operators allocate assets to minimize idle time and costly rehandles. Designers often include agent-based elements to model decision-makers such as planners and dispatchers in greater detail; agent-based simulation can capture human decision variation.

Tools vary from AnyLogic prototypes to bespoke platforms. Many teams combine discrete event simulation with visualization dashboards for clearer insights. An integrated simulation lets teams run multiple scenarios quickly. Also, simulation provides decision support for layout changes, staffing shifts, and equipment purchases. Finally, the output guides investments and operational rules that improve throughput and reduce downtime.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Automating operations in an automated container terminal and container port

Automation changes how terminals operate. Remote-operated cranes, automated straddle carriers, AGVs, and automated RTGs redefine roles on the yard. An automated container terminal reduces human exposure to high-risk tasks and tightens schedules. Importantly, such systems require reliable telemetry and an operation system that supports automated decision loops.

Crane performance sits at the center of automation metrics. Teams track crane utilization, idle time, and moves per hour. Improving utilization by better sequencing and job batching raises quay throughput. For example, targeted scheduling reduces idle windows and balances workload across cranes. Loadmaster.ai’s approach layers AI agents that work with the TOS to improve stowage and dispatch choices. This reduces rehandles and evens workload across quay cranes and yard equipment.

Digital twin integration brings real-time monitoring and predictive capabilities to life. Platforms that combine DES with a digital twin enable continuous model updates and faster responses to disturbances. As reported in recent research, “The integration of digital twins with discrete event simulation represents a paradigm shift” in resilience and sustainability assessment (digital twin and DES integration). That quote captures the value of merging live telemetry with a representative simulation model.

Maintenance prioritization also improves with these tools. A decision support layer can schedule preventive and corrective actions to minimize downtime. Evidence shows simulation-guided repair prioritization cut equipment downtime by roughly 25% in a port study (decision support for resilience). Therefore, operators can sustain higher availability for cranes and handling equipment while protecting throughput and service levels.

To read about automation deployments and best practices, terminal teams often consult resources about automated terminals and predictive maintenance. For example, our team recommends checking an automated terminal implementation guide to align automation with operations and control systems automated terminal. Also, predictive maintenance links help reduce crane downtime in deepsea and inland port contexts predictive maintenance.

Optimisation of the inland container supply chain

Optimisation targets flow efficiency across rail, road, and barge interchanges. First, mapping the inland container flow clarifies bottlenecks. Then, teams test scheduling algorithms and resource-allocation rules. The goal is to support the multimodal links that feed the container yard and the wider port system. In many corridors, trucks and rail handle the majority of inland moves. Optimisation therefore focuses on gate sequencing, rail block planning, and barge berthing windows.

Algorithms for scheduling range from heuristic rules to mathematical optimization. Reinforcement learning introduces adaptive policies that learn from simulation experience. Loadmaster.ai uses RL agents to generate robust strategies for stowage and dispatch without heavy reliance on historical data. The agents train inside a digital twin and then operate alongside the TOS. This closed-loop setup helps terminals improve crane productivity, reduce travel distances, and balance workloads across stack areas.

Quantitative impacts are significant. Studies indicate optimized scheduling and resource allocation can boost throughput by 15–20% and cut dwell times considerably (throughput gains). Such improvements convert directly into lower operational costs. Also, emissions drop when vehicles idle less and travel shorter distances. Sustainability gains therefore follow optimization efforts in the inland network.

Optimisation must also account for modes of transportation and the broader transport system. For instance, rail and road constraints, barge availability, and terminal stacking rules all matter. Integrated simulation supports joint optimization across these elements. For more on optimizing container stacking for yard operations, see our practical guide on container stacking strategies optimizing container stacking. Also, techniques for equipment dispatch can reduce empty driving and improve resource efficiency equipment dispatching.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Assessing simulation results in maritime container terminal operations

After running scenarios, teams evaluate simulation results to check KPIs. Key performance indicators include crane moves per hour, average truck waiting time, container dwell, and rehandle counts. Also, throughput and utilization metrics determine whether scheduling changes met targets. A focused set of KPIs keeps analysis actionable and tied to operational goals.

Scenario testing covers peak demand, vessel delays, and equipment failures. For example, running a delayed vessel scenario shows how congestion propagates through the yard and gates. The tests reveal where surge capacity will be most effective. They also help prioritize investments in handling equipment, additional cranes, or gate automation.

Resilience metrics include downtime reduction and recovery time after incidents. One study reported simulation-based prioritization reduced equipment downtime by about 25% (resilience case). Simulation also quantifies the value of surge capacity and temporary labor. With these insights, port managers can justify capital or operational changes that strengthen performance.

Decision support follows from clear, repeatable comparisons of trade-offs. For example, adding a quay crane might raise throughput but increase yard congestion. The simulation shows both effects so managers can choose balanced options. In practice, the simulation model and integrated simulation tools enable teams to evaluate its performance under many configurations.

Tools such as AnyLogic support both discrete event simulation and agent-based simulation in a single environment. This lets modelers test both high-level flows and detailed decision logic. Using simulation results combined with visualization and dashboards makes findings accessible to stakeholders. Ultimately, the data-driven view reduces uncertainty and guides strategic investments in port environments and equipment.

Case study of an inland container terminal in a container port

We present a case study of an inland terminal serving a busy container port. The selected site faced yard congestion, uneven crane workloads, and long truck waits. The layout is relatively compact and required smart stacking and dispatch rules. The study was conducted using a DES-based approach coupled to a digital twin that represented current operational conditions.

The team configured scenarios to test gate peak loads, rail arrivals, and export and import surges. The simulation model captured inbound and outbound flows, container stacking rules, and container loading and unloading processes. In addition, constraints for container storage and handling equipment schedules were included. The integrated simulation allowed planners to trial new yard-strategy policies safely.

Results showed an approximate throughput gain of ≈18% across the modeled period. The simulation results also revealed lower dwell times and fewer rehandles. Cost savings came from reduced truck idle time and better allocation of handling equipment. Moreover, resilience improved because repair and maintenance could be prioritized to protect high-impact cranes and vehicles.

Lessons learned include the value of a closed-loop optimization. By training RL agents in the digital twin, the terminal found non-intuitive work assignment and stacking policies that outperformed historical rules. Port managers found the recommendations executable and aligned with operational constraints. For teams planning similar pilots, we recommend starting with a focused block and scaling once KPIs stabilize. Also, review port container and berth planning best practices to align quay and yard objectives berth and crane planning.

Finally, the case study shows how simulation supports future research directions. It suggests exploring energy use and emissions alongside throughput metrics. It also highlights the importance of integrating TOS data and telemetry so that the model reflects current operational realities.

FAQ

What is an inland container terminal?

An inland container terminal is a logistics facility that handles container flows away from the seaport. It connects maritime hubs with the hinterland by rail, road, or barge and provides storage, consolidation, and transfer services.

How does discrete event simulation help terminal planning?

Discrete event simulation recreates terminal activities as sequences of events, such as crane lifts and truck arrivals. This lets planners test schedules, resource mixes, and layout changes without disrupting current operations.

Can simulation improve crane utilization?

Yes. Simulation highlights idle periods and workload imbalance. By testing different sequencing and dispatch rules, teams can increase crane utilization and quay throughput.

What role does a digital twin play in terminal simulation?

A digital twin provides real-time alignment between the physical terminal and the model. It enables continuous updates, near-real-time analysis, and predictive maintenance planning.

Do automated terminals need different simulation models?

Automated terminals require models that include automated equipment behavior and control logic. An automated terminal model should also simulate communication delays and failover strategies to ensure robustness.

How much throughput improvement can be expected?

Simulation studies report throughput improvements in the range of 15–20% with targeted optimization of scheduling and resource allocation. Actual results depend on layout, traffic mix, and the intervention chosen.

Is it necessary to use historical data to train AI for terminals?

No. Approaches that train AI agents inside a simulated digital twin can be cold-start ready. They learn policies by interacting with the model without relying solely on historical logs.

What are common KPIs to track after simulation?

Common KPIs include moves per hour, truck waiting time, container dwell, rehandles, and equipment downtime. These KPIs link directly to operational costs and service levels.

How do multimodal links factor into terminal simulation?

Multimodal links such as rail and barge affect gate scheduling and yard capacity. Modeling multimodal interactions helps optimize the transport system and reduce bottlenecks.

Where can I learn more about container stacking and yard optimization?

Operational guides and pilot reports provide practical steps for stacking strategies. For example, our guide on optimizing container stacking for yard operations offers actionable methods and simulation insights optimizing container stacking.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.