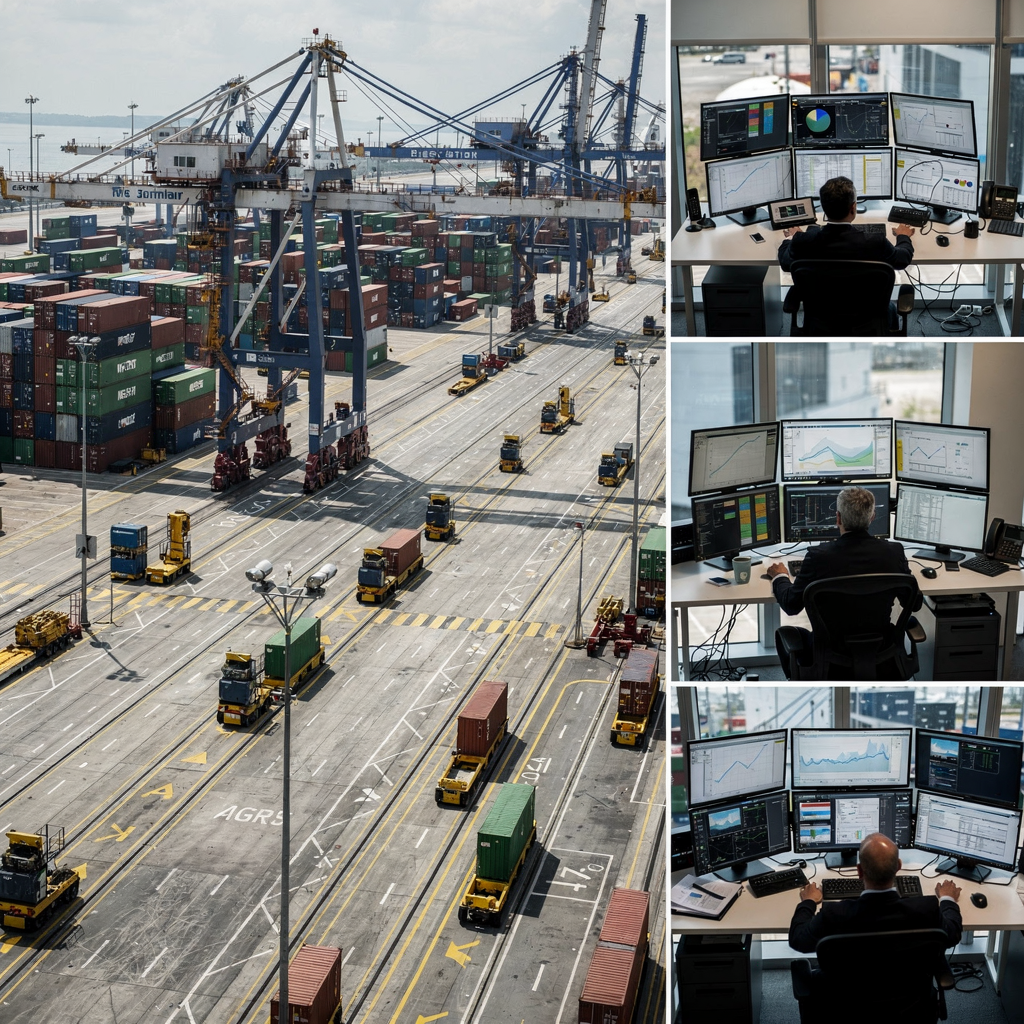

Overview of Special Container Types in terminal operations at the port

Special container types shape how a port organises flows, space, and equipment. First, refrigerated (reefer) containers keep perishable goods cool and require powered plug points and continuous monitoring. Second, hazardous materials containers carry regulated substances and demand segregation, dedicated handling zones, and written procedures. Third, out-of-gauge and oversized containers include flat racks and open-top units that exceed standard dimensions, and they force planners to allocate extra space and lifting capacity. For example, research finds “special handling has a significant impact on the productivity of container terminals,” confirming how much specialised work changes flows. Also, terminals report that special containers account for roughly 10–20% of throughput, and reefers and hazardous units together often push layout decisions toward dedicated aisles and plug banks (10–20% throughput).

Yard layout must separate reefers near power and away from hazardous segregation zones. Next, oversized units need lanes wide enough for extended-reach cranes or reach stackers. Also, standard stacks and storage yards cannot always accept irregular sizes, so a specialised terminal block may handle out-of-gauge loads and flat racks. In practice, terminals calculate terminal capacity with these special needs in mind. For instance, extra truck lanes or a separate storage yard reduces congestion, and this helps keep dwell time down. In addition, special containers interrupt standard flows and may increase handling times by 15–30% due to safety checks and equipment changes (15–30% handling time increase).

Planners should also track the shipping container mix by container type. For example, a terminal that sees many reefers must add management systems for plug availability and monitoring. Also, a site that handles hazardous materials needs formal gate procedures, segregation, and trained staff. For ports that move intermodal containers frequently, integration with road and rail schedules reduces bottlenecks. Finally, yard planning that groups similar container types together streamlines load and unload cycles, and helps stack containers more predictably. In short, special handling changes the yard plan, the quay plan, and gate operations; furthermore, it forces terminal operators to balance safety, capacity, and operational efficiency as goods are transferred through the terminal.

Equipment and Procedures for container handling in terminal

Refrigerated containers require dedicated plug-in points and monitoring systems, and terminals must fit these into yard planning and berth design. Plug banks sit near reefers, and power continuity protocols keep temperatures stable. Real-time alerts from container tracking devices tell staff if a reefer loses power. Also, a TOS-facing module can schedule plug-in slots to avoid delays and reduce container stays in the yard. In practice, terminals pair dedicated power points with management systems for visibility, and the results improve refrigerated containers’ safety and quality control (digital monitoring systems improve visibility).

For hazardous materials, segregation zones are mandatory and come with clear signage and access control. Staff follow checklists and safety checks before any move. In addition, handling equipment such as cranes must be certified for certain cargo classes, and a checklist ensures the correct lift points and stowage. Training for hazardous operations includes emergency response drills and permit-to-work systems. Also, terminal operators must follow the IMDG Code and local port rules, and management documents must reflect those requirements. A practical step is a dedicated truck gate for hazardous deliveries, and this reduces cross-traffic and exposure to other cargo. This helps lower the risk of incidents and speeds safe transfers.

Oversized loads use extended-reach cranes and flat-rack trailers, and reach stackers or gantry crane lifts may be required for unique lifts. For out-of-gauge cargo, terminals often use chassis and special lashings; they assign a hoist with a rated capacity that suits the container weight. Also, straddle carrier lanes or RTGs may not be suitable for large flats, so layout must include space for reach stackers or mobile cranes. For 20-foot container moves that involve non-standard gear, operators may deploy reach stackers or specialised lifting frames. In addition, equipment such as gantry, reach stackers, and straddle carrier units play a role depending on the block design. Finally, well-defined procedures, written permits, and pre-lift checks reduce rehandles and protect personnel when lifts are complex.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Responsibilities of terminal operators for Hazardous and Oversized Containers

Terminal operators must ensure staff are trained and certified for hazardous and oversized container handling. Specifically, operators must set training requirements and maintain records, and they must provide refresher training at regular intervals. Also, certifications should cover IMDG Code handling, safe lifting, and emergency response. For example, safety guidance emphasises governance frameworks and comprehensive training to protect occupational health and safety (governance and training matters). Terminal operators also must ensure that truck drivers and yard crews understand permit conditions for hazardous materials shipments.

Regulatory frameworks such as the IMDG Code and local port rules define many responsibilities. Consequently, terminals integrate these rules into the gate operations and shipping documents workflow. In practice, a hazardous consignment needs documentation before it can enter the yard, and segregation requirements are enforced on arrival. Also, terminals usually require a risk assessment and written stowage plan. Terminal operating staff follow incident-response protocols that include isolation, notification, and clean-up. Furthermore, terminals often maintain an incident-response team trained to manage leaks or spills, and they liaise with port emergency services.

Oversized container moves require pre-move checks and lift plans. A lift plan specifies the hoist, spreader configuration, and lashing. Also, clear communication with the vessel planner and quay team is essential when containers onto the ship are non-standard. Terminal operators must coordinate with pilots and berth schedulers to ensure large lifts do not block the quay or delay number of ships at the berth. In addition, operators must record container weight, secure special equipment such as mobile cranes, and check for overhead constraints. Finally, clear roles and responsibilities reduce dwell time and rehandles, and they help keep terminal efficiency high while ensuring safety and compliance.

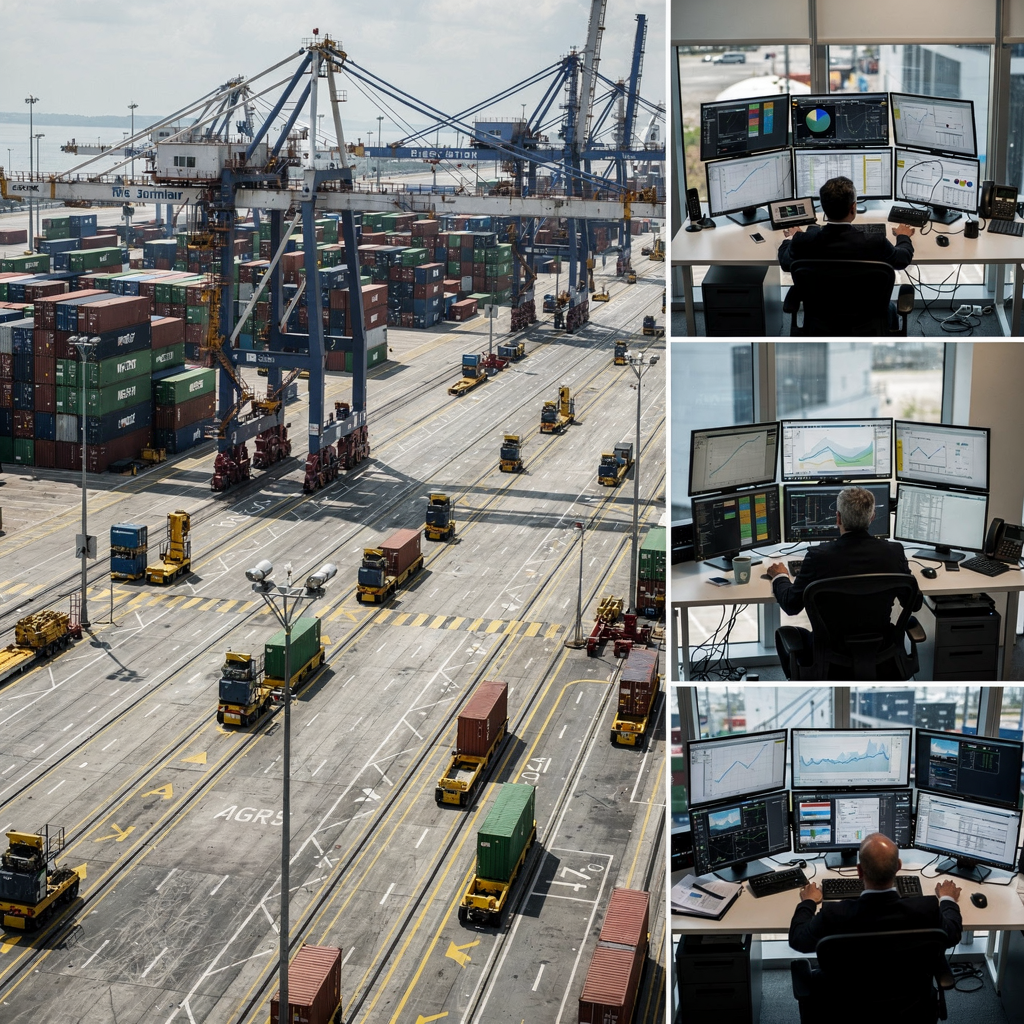

Leveraging automation, terminal automation and automated terminals for efficiency

Automation can improve special handling by reducing manual steps and improving predictability. For reefers, automated monitoring and TOS integration reduce human checks, and they alert staff to power or setpoint deviations. For hazardous and oversized moves, automation supports planning and execution, and it helps synchronise crane operations with yard movements. Research highlights that “The integration of digital technologies in container terminals is transforming how special containers are managed, enhancing both efficiency and safety” (digital integration quote). Also, automated stacking cranes and automated guided vehicles (AGVs) reduce yard congestion because they follow optimised routes and schedules, which in turn cut travel distances and rehandles.

Automated stacking cranes and AGVs play a central role in automated container terminal setups. Automated stacking reduces the need to shift loads manually, and it can protect plug-in slots for reefers by holding containers in ready positions. Moreover, an automated container terminal that links automated stacking cranes with yard management systems can cut handling times. In one case, terminals reported reductions in handling time by up to 20% when automation was carefully integrated and sequencing was improved (up to 20% reduction cited). However, integration challenges appear, especially with legacy equipment and mixed fleets. Legacy RTGs and straddle carrier units may not talk natively to modern management systems, and hardware upgrades can be costly.

To automate special handling, terminals often introduce automation in phases. First, a module that coordinates plug scheduling for reefers improves uptime. Next, integrating the yard planning layer with automated stacking systems reduces shuttle time. In addition, Loadmaster.ai uses reinforcement learning agents that simulate millions of scenarios and optimise multi-objective KPIs; therefore, the system can learn to balance quay productivity against yard congestion and reduce unnecessary moves. Also, terminal automation projects must consider safety guardrails, and they must include fallback processes for manual takeovers. Finally, successful projects combine equipment upgrades, software integration, and workforce training to achieve consistent gains.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Integrating terminal operating systems and terminal operating processes for Reefer Monitoring

Real-time container tracking of temperature and power status is essential for refrigerated containers. Terminal operating systems must expose plug availability and alert operators when a reefer loses power. Also, terminal operating systems that include a reefer module schedule plug-in slots and visualise setpoints. For example, a Yard Management Systems interface can show the location of reefers, their target temperature, and the time since last check. In addition, combined data allow analytics to predict failures, and this supports proactive maintenance of power banks. As a result, fewer spoiled goods occur and quality control improves.

TOS modules can allocate plug-in slots dynamically to avoid delays and to reduce container stays in the yard. A good TOS integrates with yard planning and vessel stowage so that reefers move in the optimal sequence. Also, TOS-agnostic plugins allow terminals to adopt new planning layers without a full TOS replacement; see resources on TOS-agnostic software plugins for terminal operations for implementation ideas. Moreover, analytics on reefer alarms reveal recurring patterns, and this helps teams schedule electrical maintenance during low-impact windows, which in turn preserves terminal capacity for peak periods.

Data analytics help forecast failures and improve quality control. For instance, if a particular plug bank shows rising alarm rates, the maintenance team can act before reefers lose setpoint. Also, container tracking that ties into predictive maintenance systems helps maintain cranes and power units. Loadmaster.ai’s approach builds a digital twin and uses RL agents so planners can test policies that protect reefers while optimising moves; therefore, the system reduces rehandles and balances yard operations. In sum, integrating terminal operating systems, yard management tools, and analytics keeps refrigerated containers safe and reduces costly disruptions to the supply chain.

Strategies to unload and automate containers onto the ship

Mapping the end-to-end workflow from yard to quay crane clarifies responsibilities and reduces delays. First, the gate validates shipping documents and places the arrival on a lift list. Next, yard teams stage the container near the berth in a pre-assigned slot. Then, the quay crane follows a stowage sequence and lifts containers onto the ship. Also, synchronisation between stowage planning and yard picking avoids last-minute reshuffles, and it ensures containers are loaded in the correct order. A well-practised flow minimises shuttle distance for internal trucks and keeps quay cranes productive.

Layout changes that reduce shuttle time include dedicated lanes for pre-staging and positioning reefers near plug banks. In addition, positioning oversized containers close to the berth and providing space for flat racks or mobile cranes reduces quay-side congestion. Terminals should also consider placing a small specialised terminal block for hazardous materials so that moves do not interfere with general cargo lanes. Furthermore, adopting a mixed-traffic strategy where automated stacking cranes handle standard stacks and reach stackers move out-of-gauge loads can cut turnaround times.

Automation synchronises unload rates with vessel stowage plans by connecting vessel planners, ASC schedules, and job dispatch. Systems that automate job sequencing send moves to equipment in the right order; in particular, automated stacking and AGVs help move the right container at the right time. Also, integrating stowage planning with yard planning reduces the need to reposition loads, and this reduces dwell time. Techniques to automate include rule-based sequencing, simulation-led optimisation, and reinforcement learning agents that learn policies across quay, yard, and gate. For guidance on synchronising ASC gantry travel with job scheduling, see research on synchronising ASC gantry travel with job scheduling in container ports for practical strategies. Finally, good automation lowers rehandles, balances equipment workloads, and helps ensure that containers are loaded in precise stowage positions while keeping crane operations efficient.

FAQ

What types of special containers require different handling?

Special containers include refrigerated containers, hazardous materials containers, and out-of-gauge or oversized units. Each category needs distinct procedures, equipment, and planning to meet safety and operational goals.

How common are special containers in terminal throughput?

Special containers typically make up about 10–20% of throughput depending on trade lanes and terminal focus. This share necessitates dedicated planning for plug banks, segregation zones, and specialised lifts (10–20% figure).

What are the key equipment pieces for reefers and oversized loads?

Reefers need plug-in points and monitoring systems, while oversized loads use extended-reach cranes, flat-rack trailers, and mobile cranes. Also, straddle carrier and reach stackers may be involved depending on yard layout.

Which regulations govern hazardous container handling?

The IMDG Code and local port rules set the main regulatory framework for hazardous materials. Terminal operating procedures must reflect these rules and include documentation, segregation, and emergency-response plans.

Can automation help with special handling?

Yes. Automation such as automated stacking cranes and automated guided vehicles can improve consistency and reduce manual interventions. In fact, terminals have seen handling time reductions when automation is integrated alongside proper planning (up to 20% cited).

How does reefer monitoring work with a TOS?

TOS modules schedule plug-in slots and display real-time temperature and power data for each refrigerated container. This integration reduces container stays and enables proactive maintenance to protect cargo quality.

What responsibilities do terminal operators have for safety?

Terminal operators must ensure staff training and certification, enforce segregation zones, and maintain incident-response protocols. They must also follow governance frameworks to meet occupational health and safety requirements (governance guidance).

How do planners reduce shuttle time for ship operations?

Planners reduce shuttle time by pre-staging containers close to the berth, redesigning lane layouts, and synchronising yard moves with vessel stowage. Automation and digital stowage tools help maintain steady crane operations.

What role does Loadmaster.ai play in these processes?

Loadmaster.ai uses reinforcement learning agents to simulate terminal scenarios and optimise quay, yard, and gate decisions. The platform helps planners reduce rehandles and balance workloads without relying solely on historical data.

Where can I learn more about integrating planning with automation?

Explore resources on TOS-agnostic plugins and ASC gantry synchronisation to understand software-first approaches. Also, case studies on automating yard stacking and berth planning provide practical steps for deployment TOS-agnostic plugins, synchronising ASC travel, and optimising container stacking.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.