simulation and terminal: Foundations of equipment scheduling

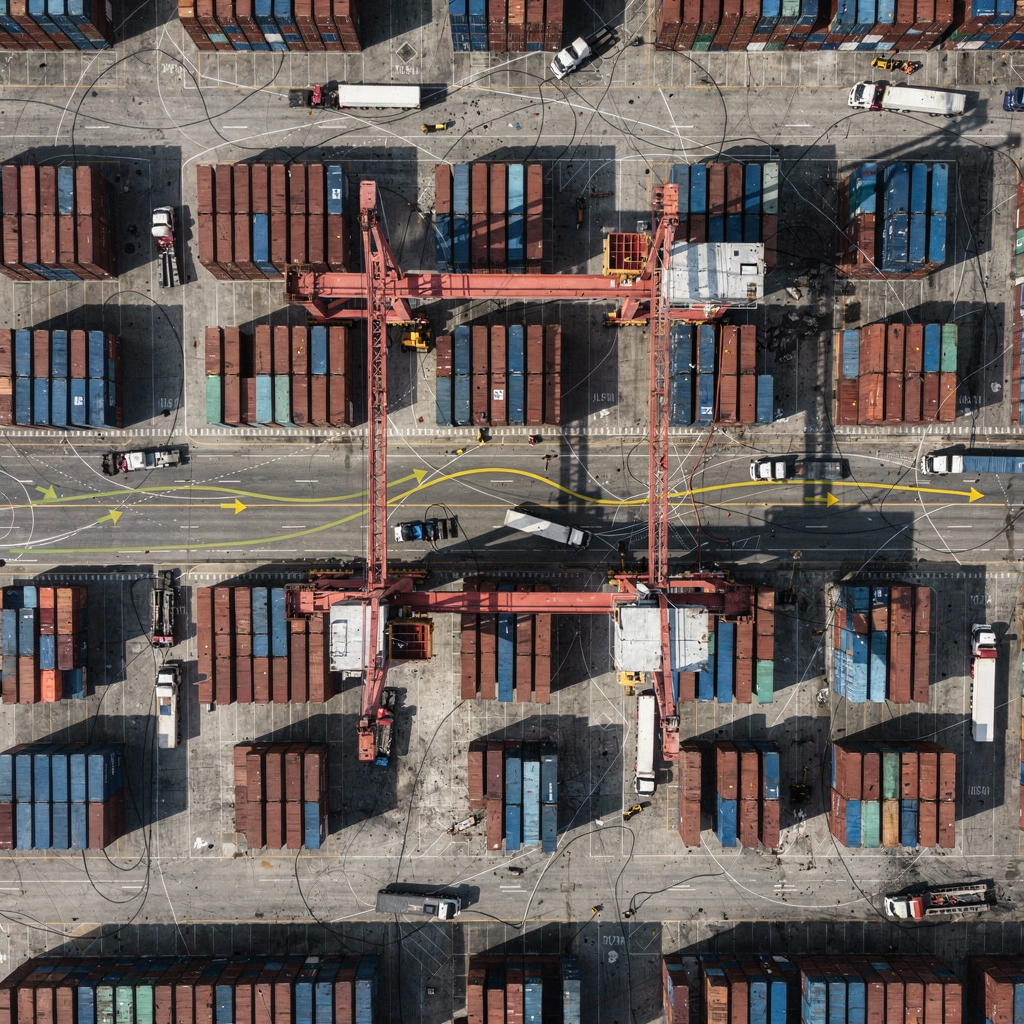

Terminal equipment scheduling directs how resources move and work inside a terminal. It covers cranes, trucks, yard equipment and gate staff. In container terminal, bulk terminals and liquid terminals the planner must match vessel windows, truck arrivals and storage capacity. Simulation helps planners test rules and see effects before they change operations. For example, Arena and other tools show how scheduling or resource allocation affects efficiency with receiving, distribution, and warehousing [Rockwell Automation]. Also, simulation captures the interaction between quayside crane, gantry and yard trucks. It models truck queues. It models crane cycles. It models storage stacking and retrieval. The result is a practical map of system dynamics that teams can use to improve terminal choices.

Key performance indicators matter. Throughput, utilisation rates and turnaround times form the backbone of operational targets. Throughput sets revenue potential. Utilisation measures how busy terminal resources are. Turnaround time drives vessel schedule performance and demurrage exposure. A terminal that runs effective scheduling often shows 20–30% higher equipment utilisation and 15–25% lower vessel turnaround time when it uses advanced scheduling solutions like terminal scheduling from Emerson [Emerson TerminalScheduler].

Simulation supports those KPIs by mapping variables in a simulation model such as arrival patterns, crane speed, travel time and stack density. Planners can adjust rules and then run what-if scenarios. Real operators gain confidence. Also, decision makers see the expected impact on waiting times and idle time and demurrage. This makes it easier to prioritize investments in terminal facilities and equipment. For more on how to set up realistic tests, teams often consult detailed guides about how to simulate container terminal operations (how to simulate container terminal operations). Finally, using simulation early in design reduces risk and helps align stakeholder expectations.

digital twin and simulation model with port simulation software: Building accurate operational models

Digital twin brings a real-time copy of the terminal into a simulation model. The twin syncs with telemetry, telematics and the TOS to reflect current yard state. Then the twin feeds live data and the software runs scenarios. Real-time feeds improve fidelity and make the model a dependable tool for planners, port authorities and operations teams. Emerson’s approach highlights visualizing and managing the flow of liquids and equipment so scheduling remains both efficient and compliant with safety standards [Emerson].

Two modelling schools dominate port simulators. Discrete event models represent moves and service cycles as distinct events. Agent-based or multi-agent designs simulate individual resources—each truck, crane or operator—as an autonomous actor. Discrete event performs well for queuing and berth allocation. Agent-based yields better emergent behaviour for complex yard interactions. Both types appear in leading port simulation software. For discrete event examples look to Arena, and for digital twin capability review Simio [Simio]. AnyLogic also supports hybrid approaches that combine discrete event and agent-based logic, which helps when you need customizable behaviour from individual equipment or staff.

Building a valid simulation model requires careful selection of variables in a simulation model, such as service time distributions, travel distances, reprioritisation rules and environmental factors. Teams then calibrate against historical throughput and real-world event logs. KBC Global makes the case that “for operations and production scheduling teams to meet daily targets, it requires a more accurate representation of the facility with more actual data” [KBC Global]. Therefore, a port or terminal gains when it integrates data, validates assumptions and runs stress tests to capture edge cases.

Port and terminal simulation software now offers dashboards, 2D and 3D views, and web-based interfaces for planners. A good port simulator functions as both a design tool and a continuous decision support platform. Planners who want to learn which software products suit their needs can compare features in dedicated reviews and product pages like the guide to what simulation software do container terminals use (what simulation software do container terminals use). In short, a validated digital twin plus the right simulation model helps teams predict outcomes and improve terminal service levels.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

allocation and automation in gantry operations: Improving resource allocation

Automation touches gantry scheduling, stacking and dispatch. Terminals that combine automated allocation strategies with intelligent allocation rules lower travel times and balance workload. For example, automated allocation can route tasks to the closest available gantry and then sequence moves to reduce shifters. Loadmaster.ai trains RL agents inside a digital twin to allocate and coordinate quay, yard, and gate moves. This approach reduces rehandles and evens crane workload, while maintaining operational guardrails. Our JobAI and StackAI agents show how multi-agent policies can balance competing KPIs in a risk-free environment.

Dynamic scheduling algorithms use prioritisation rules, cost functions and optimization algorithms to decide which job to assign next. Some terminals use linear programming for batch decisions. Others rely on metaheuristics or reinforcement learning for continuous control. Discrete event and agent-based simulation help evaluate each algorithm under realistic demand profiles. Using simulation, teams can compare strategies and measure impact on idle time and demurrage and on idle time and demurrage across scenarios.

Quantified benefits are compelling. Advanced allocation reduces idle time by up to 40% in studies and vendors cite 20–30% increases in utilisation for equipment when schedules adapt in real-time [Rockwell Automation]. Also, better allocation lowers waiting times in truck lanes and the queue at the gate. Terminals that want to streamline resource allocation should run a port simulator and then validate results with a short pilot. For more on matching allocation to equipment telemetry see our equipment utilisation simulation guide (equipment utilisation simulation). Finally, automated allocation supports risk mitigation and disruption response by reassigning tasks when breakdowns happen.

terminal scheduling and optimization in port and terminal: Strategies to optimize terminal performance

Combine scheduling methods with mathematical optimization to get robust plans. Terminals often use linear programming for berth and crane allocation. Then they layer metaheuristics to tackle large combinatorial cases. Reinforcement learning offers next-generation control that learns time-sequenced actions to improve terminal performance when conditions change. Optimization and simulation teams should partner. Simulation provides realistic test cases while optimization finds candidate solutions. Together they improve KPI outcomes.

Models must respect safety, regulatory and operational constraints. Include load limits, exclusion zones, prescribed handling times and labour rules. These constraints feed into the system requirements that guide the software product and the software license you choose. Terminal scheduling must also account for environmental factors, such as tide windows and weather, when assigning quayside crane work. Emerson notes that their software helps maintain safety and compliance while reducing turnaround times [Emerson].

Benefits stack. Terminals that adopt simulation-supported terminal optimization report measurable gains. For example, operators often see 20–30% higher equipment utilisation and 15–25% lower vessel turnaround when they use advanced scheduling and digital twin approaches [Simio]. In practice, those gains translate into lower demurrage and higher customer satisfaction. Planners also gain tools to manage trade-offs between yard congestion and quay productivity. To explore practical modelling techniques for berth planning and stacking policies consult our page on simulation tools for port berth scheduling optimisation (port berth scheduling optimisation).

Finally, a combined optimization strategy includes continuous validate steps. Validate the model with measured data, then tune. Run what-if scenarios for current and future needs. This process helps planners allocate resources more effectively and reduce costly firefighting. The result is a terminal that can consistently optimize throughput and protect service levels during peaks.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

simulation-based training and case studies to validate real-world strategies

Simulation-based training helps upskill teams. It provides a risk-free environment where operators can test new rules. Trainers can replay incidents and show best-practice responses. This shortens learning curves and reduces on-site errors. For terminal operators, simulation training also preserves tribal knowledge. When senior planners retire teams can transfer judgment via scenario libraries. Using simulation is a proven method to teach dispatch, quay management and yard strategy without interrupting real-world service.

Case studies show the power of this approach. Emerson’s TerminalScheduler provides a clear example of a software product that offers visualization and scheduling for liquids terminals and claims reduced turnaround times and increased throughput [Emerson]. Likewise, Arena has been widely used to simulate logistics and to highlight how resource allocation affects receiving and distribution [Rockwell Automation]. These case studies demonstrate measurable improvements and offer templates for validation. We also publish several simulation case studies that detail pilot-to-scale results for container terminals and yard planning (simulation case studies).

Validation steps include calibrating cycle times, matching throughput in busy periods, and comparing predicted idle time and demurrage to logged costs. Next, run stress tests that simulate equipment failures or surges in truck arrivals. Then measure the gap between simulated outcomes and real-world performance. Use that gap to refine the simulation model and update the training curriculum. Simulation modeling helped teams reduce rehandles and shorten job completion times in multiple trials.

Finally, simulation-based training supports change management. It gives planners, port authorities and other stakeholders a shared visual feedback loop. This builds consensus and speeds deployment. For terminals that want to improve terminal resilience, simulation-based training pairs well with automated agents and decision support dashboards to create a stable, repeatable operating model.

decision support for port terminals and terminal performance: Techniques to optimize throughput

Decision support tools turn simulation results into operational actions. Interactive dashboards present KPIs, queues and predicted delays. They let planners run what-if analysis and compare dispatch rules in minutes. A dashboard simplifies complex datasets so stakeholders can prioritize investments. For instance, berth planning modules analyze vessel schedules and propose shifts that reduce waiting times and demurrage. Many teams use these visual tools to streamline business processes and to communicate trade-offs clearly.

Methods to optimize throughput include berth planning, dynamic stacking policies and scheduling buffers that absorb variability. Berth allocation aligns quay labour and cranes to reduce vessel idle time. Stacking policies control container yard density and reduce travel distances for RTGs and straddles. Buffers protect the quay during short-term surges. Together these methods are part of a terminal performance program that combines simulation, optimization and hands-on operations tuning.

Emerging trends accelerate decision support. AI-driven decision support and predictive analytics now add forecasting for gate peaks and equipment failure. Reinforcement learning agents can run inside a digital twin and produce policies that adapt to changing demand. Loadmaster.ai uses RL agents to generate policies that improve crane productivity, balance yard workload and shorten driving distances. The agents run millions of simulated decisions to learn robust strategies without relying on historical data. This approach proves useful for terminals that lack clean history or that face rapidly changing vessel mixes.

Decision workflows must remain customizable and auditable. Planners need control over KPI weights and hard constraints. They also need tools to validate policy decisions before live rollout. Using a tool for port and terminal that includes simulation is a practical path to better results. To dive deeper into decision support and simulation integration check our terminal decision support simulation guide (terminal decision support simulation). Ultimately, simulation is a powerful tool that helps port terminals improve throughput, reduce risk and manage current and future needs.

FAQ

What is terminal equipment scheduling simulation?

Terminal equipment scheduling simulation models how cranes, trucks and yard equipment interact. It uses data and rules to test schedules and to predict KPIs like throughput and turnaround time.

How does a digital twin differ from a traditional simulation model?

A digital twin syncs with real-time telemetry to reflect current yard state. A traditional simulation model may use historical inputs and static scenarios. The twin supports live decision support and ongoing validation.

Which software do terminals use for port simulation software?

Popular choices include Simio for digital twin and Arena for discrete event modelling. AnyLogic also offers hybrid capabilities. For practical comparisons see our guide on what simulation software do container terminals use (what simulation software do container terminals use).

Can simulation minimize demurrage and waiting times?

Yes. By testing berth and crane allocations ahead of time, simulation reduces waiting times and idle time and demurrage. Simulation helps planners choose schedules that lower costs and improve customer satisfaction.

What role does automation play in gantry operations?

Automation can assign jobs to gantries and route trucks to reduce travel. It pairs with allocation algorithms and a port simulator to balance workload and to reduce rehandles.

How do you validate a terminal simulation model?

Validate by calibrating model inputs, comparing simulated throughput to recorded data and running stress tests. Then refine parameters until simulated results match real-world performance closely.

Is simulation-based training effective for terminal operators?

Yes. Simulation-based training offers a risk-free environment to rehearse responses and to transfer tacit knowledge. It shortens ramp-up times and reduces on-site errors.

What improvements can terminals expect from terminal optimization?

Terminals often report higher equipment utilisation and shorter vessel turnaround. Studies and vendor reports cite 20–30% better utilisation and 15–25% faster turnarounds when using advanced scheduling tools [Simio].

How does Loadmaster.ai fit into simulation and optimization workflows?

Loadmaster.ai trains RL agents inside a digital twin to create policies for stowage, stacking and dispatch. The approach requires no historical data and focuses on measurable KPIs with operational guardrails. It integrates alongside existing TOS systems and supports pilots to full-scale rollout.

Where can I find more practical guides and case studies?

Our site contains practical resources, including simulation case studies and guides on capacity planning and bottleneck reduction. Start with the simulation case studies page to see pilot outcomes and lessons learned (simulation case studies).

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.