Container terminal challenges in quay crane scheduling

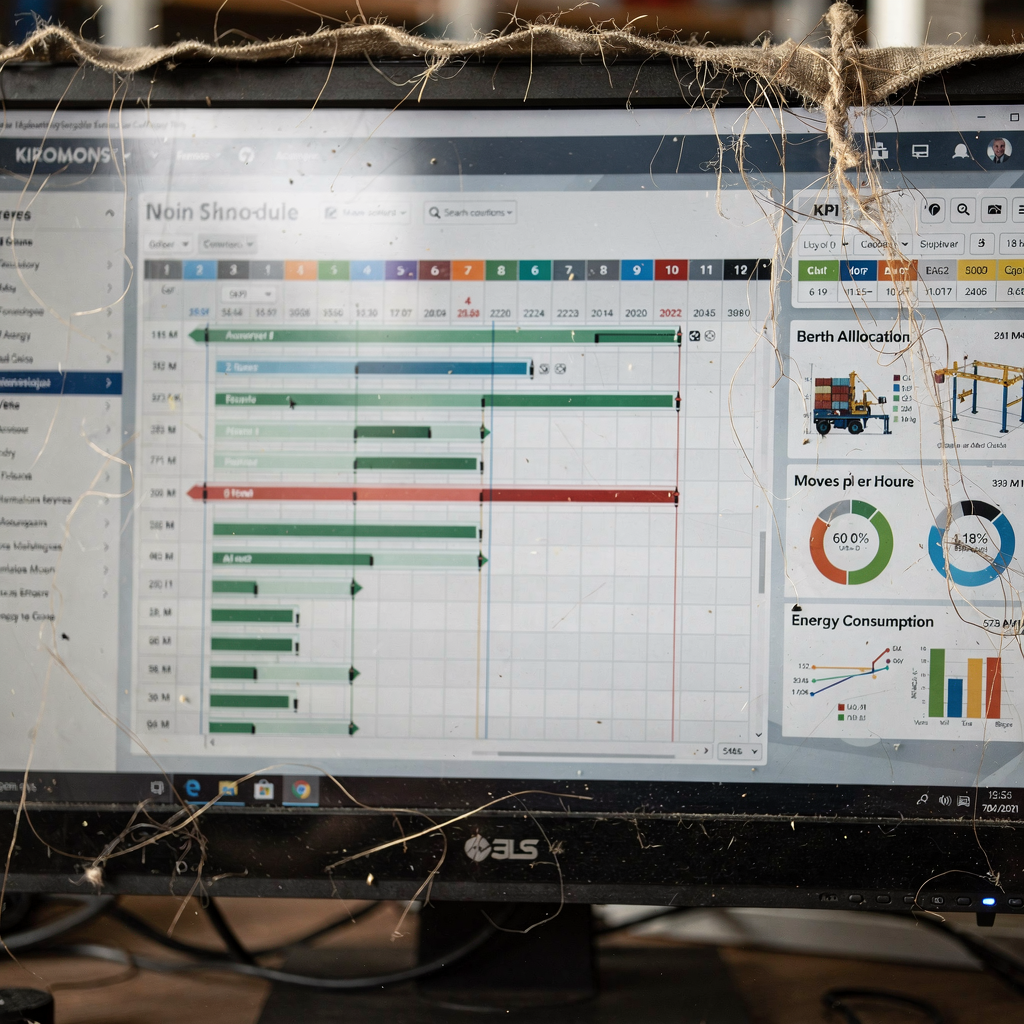

The quay crane scheduling problem sits at the heart of berth management. In a busy port, terminal planners must coordinate loading and unloading for multiple container ships while avoiding interference among cranes and yard services. The term QCSP sometimes appears in research focused on sequencing and resource allocation. Ship planners and terminal managers use QCSP models to allocate time slots, cranes and trucks so that vessel dwelling time shrinks and berth utilization rises. First, define key metrics. Moves per hour (MPH) and gross moves per hour (GMPH) measure how many container handling cycles a single quay crane completes each hour. Operators also track overall equipment effectiveness (OEE) to capture availability, performance and quality losses. For example, a well-tuned quay crane can reach 30–45 MPH under the right conditions, which shortens vessel time on berth and increases throughput; see empirical analysis of crane productivity for details Crane productivity optimisation in port operations.

Second, acknowledge the interplay with yard and gate. Scheduling of quay cranes must consider yard crane availability, truck flows and pre-stow plans. This integration reduces rehandle and waiting. In practice, berth allocation and quay crane assignment link tightly to truck dispatch and container stacking. Integrated berth allocation models and berth allocation heuristics can reduce conflicts and speed processing; these models appear in studies that test combined scheduling models Berth Allocation and Quay Crane Assignment Considering the …. Third, operational constraints raise a computational burden. The scheduling problem for multiple cranes has combinatorial complexity. Exact solutions work for small instances. Yet, for large-scale terminals solving large-scale QCSP instances, planners rely on heuristic and metaheuristic algorithm strategies that trade optimality for run time. In this context, metaheuristics such as tabu search and hybrid metaheuristics provide robust results, while particle swarm optimization and hybrid approaches appear in comparative research works.

Finally, real terminals using automation face extra constraints. Automated container terminals using AGVs or automated guided vehicles (AGV) require different timing rules for truck arrival and handover. To explore yard-side interactions, see multi-vessel crane scheduling optimization tools that simulate truck arrival patterns and stacking density multi-vessel crane scheduling optimization for deepsea ports.

Crane downtime and maintenance: analysing key loss factors

Downtime and speed reduction create the largest share of equipment losses at the quayside. Researchers identified six primary loss categories that lower crane output. These categories include mechanical breakdowns, control system faults, operator-induced slowdowns, scheduled maintenance overruns, suboptimal parts replacement strategies, and electrical degradation that increases handling time. A focused case study of Jakarta terminal equipment found that eliminating losses tied to reduced speed and breakdowns can materially lift OEE; the work quantifies potential gains of up to 15% when key losses are addressed Quay Container Crane Productivity Effectiveness Analysis. In practice, operators track loss events and assign root causes so maintenance teams can act faster.

Quay crane life cycles matter. Most ship-to-shore cranes have an expected lifespan around 30 years. Over that period, electrical control systems and mechanical parts age. That deterioration changes hoist and trolley responsiveness, which raises handling time and rehandle probability. A study on lifecycle extension recommends planned retrofits to restore kinematic parameters and maintain overall efficiency Quay Crane Performance Improvement and Lifecycle Extension: Retrofit. Preventive maintenance is one lever. Predictive maintenance is another. Statistical lifetime analysis and downtime prediction reduce unexpected outages, and some teams report downtime reductions of roughly 25% with predictive strategies Port Equipment Downtime Prediction and Lifetime Data Analysis.

Quantify the operational impact. When a quay crane slows by only 5% in cycle speed, the compound effect across the berth can increase vessel dwelling time by hours. When multiple cranes face similar slowdowns, berth utilization and port productivity fall. Thus, terminals focus on early detection of electrical control faults, which often precede larger failures. In many terminals, retrofitting PLCs and drives restores performance, reduces rehandle and supports double-cycling where safe. For terminal managers planning maintenance, integrated operation models that include quay crane maintenance help balance servicing with peak demand Integrated operation models with quay crane maintenance.

Finally, digital tools aid maintenance planning. Condition monitoring, neural network anomaly detection and machine learning models predict fault patterns, and the results feed into a mathematical model for scheduling maintenance windows. These tools reduce operational costs and minimize unplanned downtime.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Metaheuristic algorithm frameworks for the Quay Crane Scheduling Problem

The Quay Crane Scheduling Problem combines sequencing, spacing and resource balancing. It is an optimization problem that must respect inter-crane safety zones, handling time, and truck arrival patterns. Metaheuristics shine because they scale to realistic terminal sizes while delivering high-quality solutions. Common metaheuristic algorithm types include genetic algorithms, tabu search, simulated annealing and particle swarm optimization. Multiple metaheuristics are often combined to form hybrid metaheuristics that capture complementary strengths. In many research works, hybrid approaches outperform single-method heuristics on solution quality and convergence speed.

Algorithm design must include berth allocation and quay crane assignment. Integrated berth allocation and crane assignment models reduce conflicts by coordinating ship positions and crane pools. Benchmarks show that combining berth allocation with QC scheduling cuts vessel waiting time compared to sequential planning. For terminals exploring integrated approaches, see simulation and planning tools that emulate vessel arrival patterns and yard density impacts impact of inland yard density on throughput. In terms of computational complexity, the QCSP becomes NP-hard as the number of container ships, multiple cranes and loading plans grows. Exact solutions and mixed-integer programming models provide optimal results for small instances, but they struggle when solving large-scale practical cases. Therefore, many ports rely on metaheuristics to obtain near-optimal solutions quickly.

Metaheuristics can incorporate dynamic scheduling features. Scheduling using rolling horizons and stochastic demand inputs yields robust plans when truck arrivals and container handling tasks vary. For dynamic scheduling and real-time adaptation, some frameworks use a model using reinforcement learning or neural network surrogates to speed evaluation. For example, reinforcement learning research applies to crane and yard dispatching in simulation environments reinforcement learning in terminal operations. Finally, hybrid metaheuristics such as genetic algorithms combined with tabu search or local search heuristics deliver both exploration and exploitation. This mix improves solution quality and convergence rate while keeping computational demands manageable.

Genetic algorithms integration for quay crane optimisation

Genetic algorithms provide a flexible template for QC scheduling and berth planning. In a typical encoding, a chromosome represents a sequence of service tasks assigned to each quay crane. The algorithm evaluates fitness based on vessel turnaround, dwelling time and rehandle counts. Using crossover and mutation operators, the population evolves toward schedules that minimize delays and balance crane workload. Importantly, researchers often adopt a scheme using a hybrid genetic algorithm to blend population-based search with problem-specific local search. This hybrid approach improves solution quality and convergence rate in many testbeds.

A practical case study demonstrates benefits. A study applying a hybrid GA to the quay crane assignment problem found measurable gains in QC utilization and reduced vessel delays. The research reported that hybridization produced faster convergence than stand-alone genetic algorithms, and it reduced total service time compared to greedy heuristics. In associated sensitivity analyses, increasing multiple cranes per vessel and tuning kinematic parameters produced up to 20–30% gains in throughput under certain scenarios Modelling and Simulation of Ship-to-Shore Cranes. In addition, hybrid metaheuristics that integrate particle swarm optimization for local refinement sometimes beat single-method runs.

Implementation details matter. Solution encoding must prevent illegal overlaps between adjacent crane work zones. Selection and crossover should preserve feasible assignments while enabling exploration. Mutation rates balance diversification and intensification. Also, repair operators and constraint-aware decoding reduce infeasible offspring. When terminals adopt such methods, they often integrate berth allocation and truck scheduling so that handling tasks align with yard capacity. A study of Tangier port included a model using combined berth and QC scheduling; the case study of tangier med highlighted local constraints that affected crane cycles and truck handovers. The study of tangier med port recommended hybrid approaches for the specific quayside layout in Morocco.

Finally, genetic algorithms pair well with simulation. Planners use simulation to validate schedules under stochastic arrivals and to compute KPIs such as throughput and energy consumption. The QC scheduling framework then iterates between evolutionary search and simulation-based evaluation, leading to robust plans for container terminal optimization.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Simulation of quay crane scheduling and simulation results

Simulation models form the testing ground for scheduling decisions. A simulation captures container handling sequences, truck dispatch, yard stacking constraints and quay crane kinematics. Model components include arrival processes for container ships, berth allocation logic, QC scheduling heuristics, truck and AGV routing, and yard handling rules. The simulation outputs key performance indicators such as throughput, dwell time, moves per hour and energy consumption. Operators use these KPIs to compare scheduling model alternatives and to calibrate parameters.

Key indicators include OEE, crane utilization and rehandle rates. Simulation results often reveal bottlenecks that are invisible in static plans. For example, double-cycling an efficient QC can reduce per-container handling time but may increase yard congestion and rehandle if yard capacity is tight. To assess tradeoffs, planners experiment with mixed scenarios: different numbers of multiple cranes on a vessel, variable truck arrival rates, and dynamic electricity prices that affect energy-aware schedules. Recent models incorporate container mass data to schedule heavy lifts when electricity prices are low, which minimizes total energy consumption Optimizing Quay Crane Operations Considering Energy Consumption.

Simulation also proves essential when testing automated systems. Automated stacking cranes, AGVs and automated guided vehicles introduce timing dependencies. For automated container terminals, the handover timing between AGV and QC drives schedule feasibility. Simulation reveals how changes in handling time influence dwelling time and yard congestion. To prepare for software migrations and cutover, operators use predictive analytics and port emulation to study yard density and stacking impacts deepsea container port emulation software for planning.

Finally, simulation results guide scheduling policies. A scenario-based evaluation suggests whether to favor throughput (moves per hour) or reduced energy consumption. The findings of this study style evaluations often lead to multi-objective scheduling models that balance vessel turnaround and operational costs. Researchers combine exact solutions for small test cases with multiple metaheuristics and simulation-driven evaluation for solving large-scale systems. In practice, terminals adopt dynamic scheduling models that run frequently and adapt to real-time events, which improves responsiveness and overall efficiency.

Optimisation strategies for productivity and energy efficiency

Optimisation strategies now include energy-aware scheduling, predictive maintenance and hybrid control policies. Energy consumption drives new tradeoffs. By using container mass information and dynamic electricity tariffs, terminals can schedule heavy lifts during lower-priced intervals. This approach reduces operational costs and supports sustainability targets. Energy-efficient job allocation algorithms also minimize peak power draw and smooth crane motor usage. To explore energy allocation in port operations, see energy-efficient job allocation research energy-efficient job allocation in port operations.

Balancing moves per hour gains with sustainability matters. Terminals must weigh faster MPH against higher power spikes or increased rehandle. Multi-objective optimization models solve for Pareto-efficient schedules that minimize vessel turnaround and energy consumption simultaneously. For instance, mixed-integer programming formulations can target minimal dwelling time and minimal energy, while metaheuristics and particle swarm optimization handle scaling to realistic instances. For operational context, consider that global supply chains expect consistent turnaround. Ports that align scheduling with energy markets and predictive maintenance secure lower operational costs and better service reliability.

Maintenance policy ties into this picture. Proactive maintenance reduces unexpected downtime, thereby protecting throughput and lowering emergency repair energy and labour costs. Integration of machine learning and neural network models into maintenance planning improves fault prediction. Also, integrating email automation reduces coordination delays between operations and maintenance teams.

Finally, look ahead. Future work should explore deep learning surrogates for fitness evaluation, and testing of hybrid metaheuristics in a case study of tangier med and other busy ports such as those in Morocco. Directions for future research include tighter coupling of berth allocation, QC scheduling and yard management, refined models for handling heavy lifts and mixed stowages, and methods in port that combine automated guided vehicles, AGVs and human crews to optimize the movement of goods. These steps will help terminals increase port productivity while supporting global supply and maritime trade.

FAQ

What is the Quay Crane Scheduling Problem?

The Quay Crane Scheduling Problem (QCSP) is the planning task of assigning sequences of loading and unloading jobs to cranes at a berth. It must respect safety spacing, resource constraints and truck or AGV arrivals while seeking to minimize ship dwelling time.

How is crane productivity measured?

Crane productivity is commonly measured in moves per hour (MPH) and gross moves per hour (GMPH), plus metrics like overall equipment effectiveness (OEE). These indicators capture the speed, availability and quality of handling tasks.

Why is maintenance important for quay cranes?

Maintenance prevents breakdowns that cause the largest losses in crane availability and handling time. Predictive maintenance and timely retrofits extend a piece of equipment’s life and reduce operational costs.

What role do genetic algorithms play in scheduling?

Genetic algorithms search across many candidate schedules by evolving populations with crossover and mutation. They work well when combined with local search to improve solution quality and convergence speed for complex scheduling problems.

Can simulation help validate schedules?

Yes. Simulation models reproduce arrival variability, yard constraints and crane kinematics to test schedules under realistic conditions. Simulation results help compare alternatives on throughput, energy consumption and rehandle rates.

How do energy-aware schedules work?

Energy-aware schedules use information such as container mass and electricity price profiles to time heavy lifts when power costs are lower. This reduces total energy consumption and operational costs while keeping service levels.

Are there examples of hybrid optimisation in ports?

Numerous studies apply hybrid approaches, for example combining genetic algorithms with tabu search or particle swarm optimization. These hybrid metaheuristics often outperform single heuristics on solution quality and speed.

What is the impact of automation on QC scheduling?

Automation, including automated stacking cranes and AGVs, changes handover timing and increases interdependence between yard and quay. Scheduling must account for automated guided vehicles and precise AGV arrival windows to avoid bottlenecks.

How do terminals integrate berth allocation and crane assignment?

Terminals use integrated berth allocation models that coordinate ship placement with crane assignment to reduce idle time and interference. Integrated berth allocation improves vessel throughput and reduces waiting at anchor.

This reduces manual delays and improves the execution of optimized schedules.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.