Maritime environment and dynamic forces

The MARITIME environment exposes every container on deck to a broad set of dynamic forces. Ships experience roll, pitch and heave as primary ship motions. Roll tilts the container bays and creates lateral loads on a stack of containers. Pitch shifts weight longitudinally and changes the forces acting on twistlocks and lashing bars. Heave produces vertical accelerations that alter the effective weight of containers in the upper tiers. Each motion combines with wind and wave action to generate lashing forces that secure the container stacks.

Waves and wind act together to create complex loads. Wind pressure pushes on exposed containers so stacks act like sails and amplify lateral loadings. Wave impacts and ship accelerations can multiply static weight by factors of 1.5 to 2 under severe sea conditions, so the forces on the lashing rise dramatically during rough weather. Experimental research documents that dynamic loads can exceed static estimates, and that simulation must include these multipliers to predict safe securing and avoid stack collapses at sea [source]. Therefore, terminals and ship crews plan for greater loads than the simple weight of each container.

These dynamic forces affect terminal handling and safety in multiple ways. First, stack stability during loading or discharging changes when wind gusts or residual roll remain. Second, heavy stacks on certain bays can change how cranes lift and place containers; on-deck handling must account for both weight and the resulting lashing tension. Third, decisions about which containers to stow on deck versus underdeck influence exposure to lashing loads and bad weather. Terminal planners often rely on stowage and securing rules and the ship’s cargo securing manual to coordinate safe lifts and reduce the risk of loss of containers during departure and transit [source].

Operators should check acceleration limits and the content of the cargo securing manual when they load heavy stacks. The cargo securing manual notes: “The basic acceleration data are to be considered as valid under the following conditions with respect to lashing,” and it guides the selection of lashing gear and securing points for each tier of containers [source]. In practice, safe stowage requires that terminal teams, ship crews and planners work together, and that they respect force limits and stack weight tables when they place containers on deck and in bays. For rapid operational decisions, many terminals now integrate AI tools that help translate stowage rules and lashing constraints into actionable moves, which reduces errors and speeds handling while protecting cargo and the hull.

Container ship stability and stacking limits

Container ship stability rests on a set of measurable criteria, notably GM or metacentric height. That parameter defines initial stability and the ship’s tendency to right itself after roll. A high GM gives faster roll periods and larger accelerations, and a low GM lengthens the roll and can lead to large angles that stress lashing. Therefore accuracy in weight declarations and distribution is essential for a safe stow and a predictable centre of gravity. Classification societies and the international maritime organization set frameworks that help shipowners and terminals compute safe loading limits, and the shipowner must ensure the stowage plan keeps the vessel within stability envelopes.

Regulators and investigators emphasise stack and tier weight compliance. The TSB report stresses that “stack and tier weights are not exceeded” as a core requirement for safe operations [source]. Stack weight tables and the ship’s cargo securing manual provide limits per bay, and they record the correct weight for each tier of containers to prevent overloading posts and twistlocks. Exceeding these limits increases the chance of stack collapses and structural damage to the hull.

Lashing forces interact with stability. Tension and compression from lashing systems transmit through lashing rods and turnbuckles into the container posts and the deck fittings. When heavy stacks raise the centre of gravity, the same sea motions produce larger moments, and the lashing must resist both lateral and vertical components. Designers account for these forces in lashing and securing gear selection, but in practice the dynamic loads depend on weather conditions and sea state. Simulation and dynamic investigation of container stacks under roll and pitch excitation show that uncontrolled lashing forces can transfer large loads to the bottom tier and the deck structure, and they can lead to structural failures if the forces on the lashing exceed design values [source].

Terminal teams must therefore integrate stability checks into stowage plan verification and yard planning. Automated checks that compare declared weights to stack weight tables reduce the risk of mis-declared weights and speed compliance. For deeper operational integration, see approaches that link vessel planning with yard planning to maintain safe loading sequences and to avoid dangerous concentrations of heavy containers in a single bay link. That coordination helps prevent both loss of cargo and costly delays caused by rework during port calls.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Container stack weight considerations and properties

Standard containers come in defined tare and payload combinations. A modern container, fully loaded, often approaches the maximum gross weight limits set by convention and by port equipment capacities. Typical twenty-foot and forty-foot units have tare and payload ranges that affect the weight of the containers when stacked. Accurate weight declarations remain critical; industry reports note that the shipping industry transported 226 million containers and that misdeclarations persist as an operational risk. The correct weight and accurate documentation reduce surprises at the quay and during lashing operations.

Weight distribution matters. Heavy containers concentrated in the upper tiers increase the centre of gravity of the stack and raise moments on the twistlocks and posts. That change affects both the forces acting and the required lashing to secure the stack. Properly distributed weight lowers accelerations transmitted through the stack and reduces the loads on the bottom tier. Terminals and ship planners implement stack weight tables and stowage plan rules to ensure the entire bay carries acceptable loads. Bays where the stack weight becomes excessive need load redistribution before sailing.

Heavier stacks demand larger lashing forces. The vertical and horizontal components of wind and wave-induced accelerations create tensile forces in external lashings and compressive forces in internal lashings. When weight increases in upper tiers, the tensile demands on lashing systems grow. Experimental comparisons show that external lashings can reduce vertical compressive loads on container posts, which lets operators plan higher allowable payloads for certain stacks. As a result, terminals can sometimes increase efficiency by adjusting lashing configuration and weight distribution, while still meeting force limits [source].

Operationally, terminals must monitor weight of the containers as they move through yard and quay. Verification software and automated stowage plan verification reduce manual errors and speed compliance checks; see methods that automate stowage plan verification in inland container terminals for ideas on reducing rework and ensuring the correct placement of heavy units link. These tools help teams avoid situations where an entire bay ends up overloaded and require last-minute lashing adjustments that delay vessel departure.

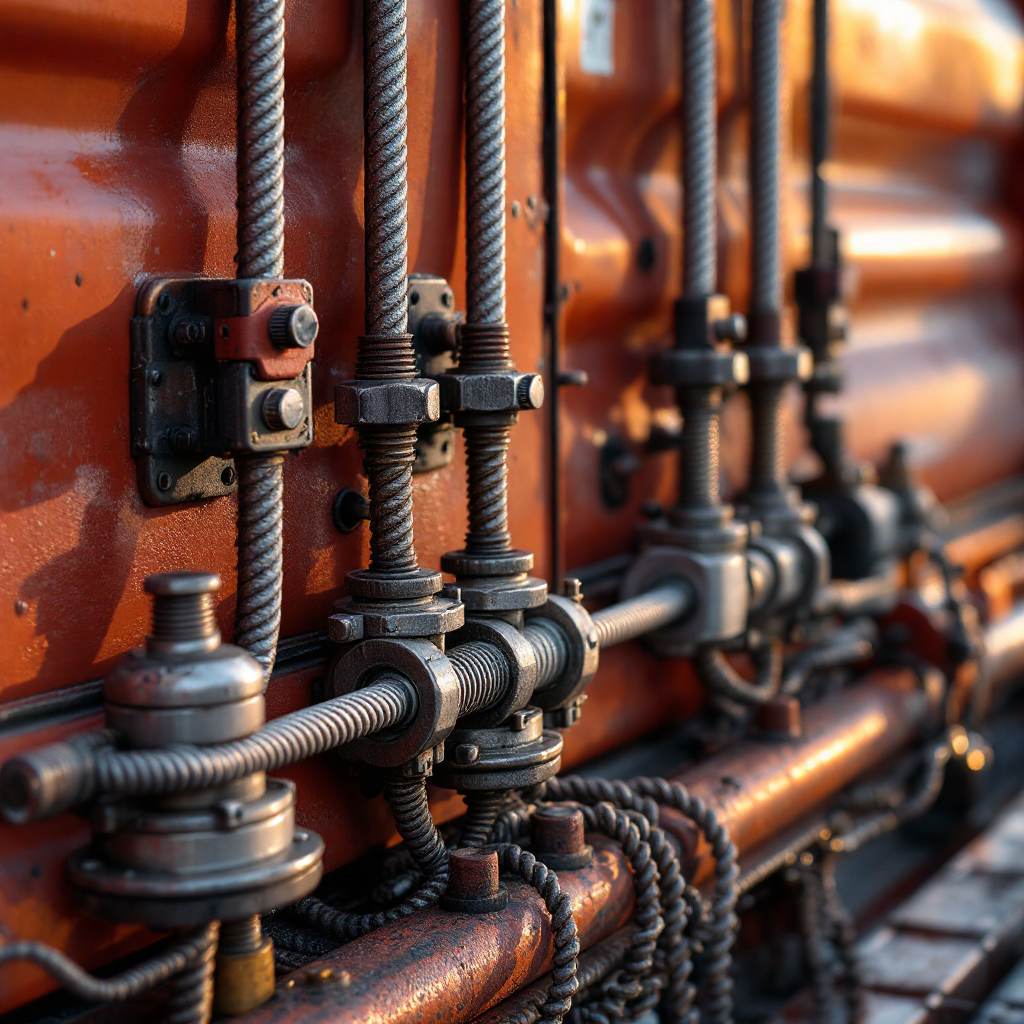

Lashing systems: external vs internal lashings

Lashing systems fall into two broad groups: internal and external lashings. Internal lashings work within the corner-post interfaces, typically adding compressive support between containers in the stack. External lashings secure the lifted side of a container stack and apply tensile force that resists uplift and lateral movement. Each configuration affects forces on the posts, twistlocks and deck fittings differently and they influence how the stack reacts during roll and pitch.

Under dynamic loads, external lashings often perform better. Research shows external lashings absorb dynamic loads more effectively because they act on the free, lifted side of the stack and reduce compressive loads on container posts. Consequently, external lashings can permit payload increases for certain container stacks, with studies quoting improvements in allowable stack weights of up to 10–15% when external lashings replace internal arrangements [source]. That benefit translates to higher payload capacity for container vessels, but operators must balance gains with hardware costs and deck configuration constraints.

Performance differences are also visible in the loads on the container lashing and securing points. Internal lashings can generate high compressive forces in the bottom tier under high vertical accelerations, and they can lead to higher strain on posts and twistlocks. External lashings move those loads into tensile elements, and they use lashing rods, lashing bars and turnbuckles to distribute the forces to deck fittings and lashing bridges. Studies that model seven-tier and four-tier stacks show a marked change in load distribution depending on which lashing system a ship uses [source].

Terminals and shipowners considering a change in lashing practice should consult stack weight tables and the ship’s cargo securing manual. A classification society or international maritime organization guidance will clarify allowable modifications. For practical port-side planning, integrating lashing choices into the stowage plan helps the quay team select which containers to move and where. When terminals combine improved lashing systems with optimized stow placements, they reduce the probability of deck stack collapses and improve overall cargo safety.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Container lashing practices and software tools

Calculating lashing forces requires understanding both static weight and dynamic load factors. Planners compute expected accelerations from ship motions and weather conditions, then multiply by container weight to estimate tensile and compressive demands. The forces acting on each lashing element determine whether lashing rods, lashings and turnbuckles meet force limits. For repeatable results, the industry recommends using formal lashing software that checks forces against stack weight tables and simulates different sea states.

Modern lashing software automates many of these calculations. For example, modules like the Easeacon lashing module evaluate stacks and flag stacks with excessive lashing forces before departure; they also help teams check compliance with the ship’s cargo securing manual and classification society requirements [source]. Lashing software must meet industry standards; Nippon Kaiji Kyokai and other societies publish requirements for lashing software so terminals and shipowners choose certified tools [source].

Software helps reduce incidents of excessive lashing forces by identifying problem stacks early. Case studies indicate that using lashing and stowage tools can improve compliance and reduce the incidence of dangerous stack configurations by about 20% in operational trials. This reduction comes from automated checks, forced prompts to correct the stowage plan, and integration with weight declaration systems. For terminals pursuing digital transformation, integrating vessel planning and yard planning systems further streamlines the process and reduces handoffs during port calls link.

Operational tips from the World Shipping Council and cargo securing guidance include verifying twistlocks and securing points, monitoring weather conditions and bad weather alerts, and ensuring correct weight declarations before stow. When planners receive accurate, timely information, they can adjust stowage plans and lashing configurations to secure the container stacks and avoid costly rework or loss of containers.

Securing points and cargo safety in container stowage

Securing points are the interface between the lashing gear and the ship. Deck fittings, lashing bridges, and corner castings on containers form a load path that transfers lashing forces safely into the hull. Proper placement and condition of these securing points determine whether the lashing systems work as intended. Regular inspection of twistlocks, lashing bars and lashing rods ensures the loads on container corner posts and deck fittings stay within allowable limits.

Best practices in container stowage focus on weight distribution and correct placement. Place the heaviest containers low and centered in the bay and avoid stacking many heavy units on a single column. That approach keeps the centre of gravity low and reduces the tensile force demand on lashings during roll. Use the ship’s stack weight tables and the content of the cargo securing manual for final checks. When terminals plan moves, they must ensure that the entire bay is within limits and that the bottom tier can accept the loads from the stacks above without exceeding compressive strength.

Operational checks help prevent deck stack collapses. Verify twistlocks, confirm locked lashing rods and turnbuckles, and ensure the number of containers loaded in each bay matches the stowage plan. Training for stevedores and crane operators should include recognition of potential load concentrations and signals to halt loading when the stack looks unstable. The World Shipping Council recommends consistent procedures for securing cargo and for handling stacks act like giant sails when wind acts on them; these procedures reduce lost at sea incidents and the risk of loss of cargo during heavy weather.

Inspection and documentation tie the process together. The ship’s cargo securing manual and cargo securing standards from classification societies outline inspection intervals and acceptable hardware conditions. Where possible, terminals should automate records and link lashing checks to the stowage plan so that any change in loads triggers revalidation. For example, integrating yard crane scheduling and dispatching with stowage verification reduces the chance that containers loaded in the wrong place create dangerous concentrations. That integration supports safe stowage and securing and reduces potential commercial impact when a bay requires rework after the vessel has already loaded.

Finally, read the signals from the sea and react early. If rough seas or severe weather is forecast, adjust the lashing arrangement, redistribute heavy units, and consider moving sensitive cargo underdeck. These steps help secure the container stacks to the deck and reduce the risk that lashing and securing gear will fail when the vessel encounters extreme forces.

FAQ

What are lashing forces and why do they matter?

Lashing forces are the tensions and compressive loads applied by lashing gear to secure containers on a vessel. They matter because they keep container stacks stable under roll, pitch and heave and they protect against loss of containers and stack collapses at sea.

How do external lashings differ from internal lashings?

External lashings secure the lifted side of a container stack and transfer forces through tensile elements like lashing rods and turnbuckles. Internal lashings rely more on compressive load sharing between containers and posts. Studies show external lashings can permit higher payloads by reducing compressive stresses [source].

Can software really reduce excessive lashing forces?

Yes. Lashing software can simulate dynamic loads, flag problematic stacks and verify force limits against stack weight tables. Trials indicate such tools can improve compliance by about 20% and prevent excessive loads before departure [source].

What role does weight distribution play in safe stowage?

Weight distribution controls the centre of gravity of the vessel and of each stack. Placing heavy containers low and balanced across the bay reduces roll-induced accelerations and the demand on lashing systems. Correct weight declarations and stowage plans support this process.

How do I check stack weight limits for a specific bay?

Consult the ship’s cargo securing manual and the stack weight tables for the vessel. These documents specify the allowable weights per tier and per bay. If you need automation, stowage plan verification tools can run these checks during planning link.

Does lashing choice affect container payload capacity?

Yes. Using external lashings can reduce compressive loads on posts and allow allowable stack weights to rise by as much as 10–15% in some configurations [source]. However, operators must weigh benefits against hardware and operational constraints.

What inspections should be done before sailing?

Inspect twistlocks, lashing rods, turnbuckles, and deck fittings for wear or damage. Verify that lashing bars are properly installed, that twistlocks are locked, and that the stowage plan matches the loaded configuration. Follow the ship’s cargo securing manual for specific inspection intervals [source].

How do weather conditions influence lashing requirements?

Bad weather and rough seas increase accelerations and dynamic load factors, which in turn raise the forces on lashings. When severe weather is forecast, reassess securing arrangements and consider moving sensitive cargo below deck or redistributing heavy containers.

What causes most stack collapses at sea?

Stack collapses often occur when weight distribution and lashing fail to account for dynamic forces, or when incorrect weight declarations lead to overloaded tiers. Contributing factors include damaged securing points, faulty twistlocks, and concentrated heavy stacks that raise the centre of gravity.

How can terminals reduce coordination friction during lashing operations?

Terminals can automate information flows between operations teams, the shipowner and stevedores so that weight, stowage and lashing data remain consistent. Tools that integrate vessel planning with yard planning and that automate job scheduling reduce manual email traffic and errors; see solutions that integrate vessel and yard planning for better operational flow link.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.