Introduction: Challenges of Deepsea Container Ports and the Need for Holistic Optimisation

Deepsea container ports face rising volumes, larger ships, and complex chains. Ultra-large vessels (ULCVs) now call at a shrinking set of hubs. The global trend in TEU growth pressures terminal layouts, crane fleets, and hinterland links. For example, the Port of Shanghai handled over 47 million TEUs in recent years, which shows scale and strain on berths and yards Port of Shanghai TEU statistic. The surge forces port operators to rethink berth planning, yard flows, and gate throughput. Congestion appears more often. Waiting time rises. Costs climb. Port competitiveness therefore depends on coordinated improvements across systems.

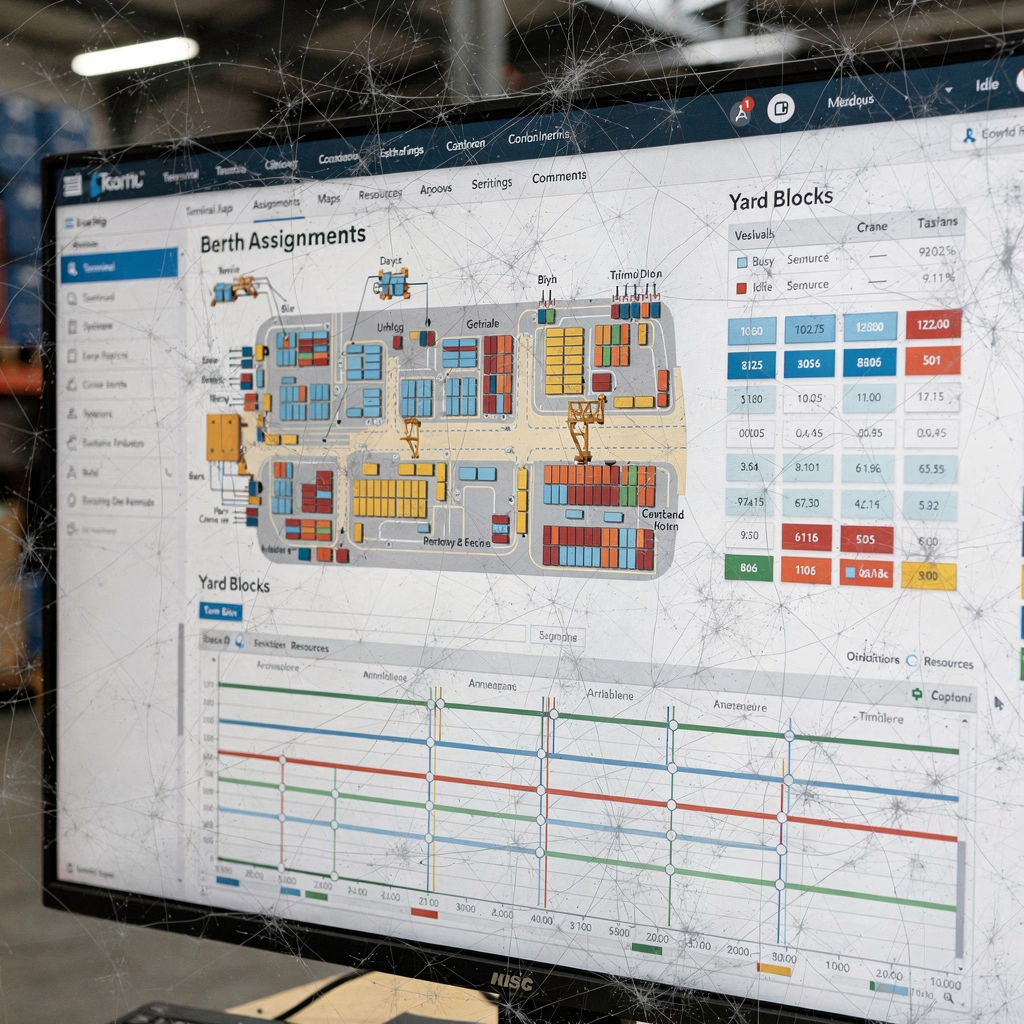

Key pain points start with berth allocation and expand to crane scheduling and yard operations. Berth allocation errors increase total waiting time and create cascading delays. A poor schedule for quay cranes raises container dwell. Yard misplacement causes rehandles and raises total cost. The assignment problem between berths and quay cranes is often solved in isolation. That raises operational friction. Terminal operations need integrated views. A holistic strategy can optimize vessel sequences, berth allocation, and yard crane moves together. This reduces idle time and lowers port congestion while preserving service levels. The challenge is an optimization problem with many decision variables and hard constraints. It must also handle uncertain arrival patterns and equipment failures.

Data and software must support short-term decisions and strategic investments. AI, IoT, and analytics give real-time visibility and predictive insight. For instance, smart sensors and connected devices feed continuous telemetry that operations teams can use to plan maintenance and shift resources before failures occur smart sensors and IoT citation. Yet technology alone is not enough. People, procedures, and digital governance must align. Otherwise, a high-performing algorithm will stall behind manual email workflows and slow triage. That is where practical automation, such as email AI agents that reduce manual handling, can help operations teams stay focused on core port tasks.

solution method: Integrating Vessel Scheduling, Berth Allocation and Crane Scheduling with AI and IoT

A coherent solution method brings vessel schedule, berth allocation, and crane scheduling into one integrated optimization model. First, create a real-time data layer. Then, use AI to predict arrival windows and equipment status. Next, feed those predictions into an algorithm that balances berth assignments and crane tasks. The model must take into account tidal windows, quay crane reach, and yard capacity. It must also respect labor shift constraints and safety rules. A successful proposed model couples short-horizon decisions with longer-term berth planning.

Predictive analytics change how resources are allocated. When a vessel’s arrival shifts, the algorithm updates the schedule and reallocates cranes. This reduces vessel idle time and shortens turnaround. An optimal solution often requires solving a multi-criteria assignment problem that minimizes total cost and berth idle time while controlling congestion. The approach uses decision variables for berth start times, crane assignments, and yard moves. The optimization model is developed to balance those variables and to find the optimal solution under uncertainty.

AI and IoT also enable condition-based maintenance and better resource forecasting. Sensors on STS cranes report health metrics. Data feeds help a scheduling optimizer avoid breakdowns by reallocating the number of quay cranes in advance. A quay crane assignment problem then becomes tractable, since the system can propose a resilient plan that tolerates partial outages. Further, an algorithmic scheduler can implement scheduling strategies that favor quick transshipment for deep-sea vessels and efficient feeder connections. For readers who want deeper technical coverage, our work links to resources on AI decision support for port operations and predictive maintenance for STS cranes AI decision support for port operations and predictive maintenance for STS cranes.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

transportation research part: Enhancing Hinterland Connectivity and Intermodal Transfers

Hinterland links are a core part of any optimization approach. Rail, road, and feeder-ship coordination must be synchronized with the vessel schedule and terminal gates. When rail slots are scarce, containers pile up at the yard and create port congestion. Conversely, well-timed rail departures reduce yard dwell and lower emission. Coordination needs both planning and operational control. For instance, digital gate systems speed gate checks and reduce waiting time for trucks. Several case studies show that automated gate validation cuts processing time drastically and improves the flow of export containers.

Intermodal transfers require precise timing. A feeder connects at a narrow time window. If the berth schedule slips, the feeder will miss the deep-sea vessel connection. That raises feeder rebooking costs and complicates the assignment problem for feeders. Transportation research therefore models the network of trains, trucks, and feeder vessels as linked arrivals with time window constraints. The model must minimize the total waiting time and the total cost across modes. In practice, operators use optimization algorithms that coordinate feeder frequency and gate throughput while meeting linehaul commitments.

Digital platforms and APIs are central to this integration. Real-time slot booking systems for road trucks can share planned arrival time and container ID with the terminal. A proactive terminal then allocates a yard position and schedules a loader. The result is fewer rehandles and smoother flows. Readers can explore smart algorithms for container location assignment and strategies for inter-terminal transport flows to see practical methods and metrics container location assignment and inter-terminal transport flows. These resources show how integrated berth allocation and quay crane decisions tie to hinterland commitments.

Operationally, companies that automate the email lifecycle for ops teams remove another hidden delay. When gate exceptions or rail schedule changes arrive by email, AI agents can parse intent, find the right booking, and route or resolve the issue. That reduces delays. It also helps port operators keep the schedule stable and the yard balanced. Overall, transportation research supports approaches that mix algorithmic scheduling, digital gates, and operational automation to reduce congestion and emissions.

computational experiments: Simulation Design for Automated Terminal Scenarios

Computational experiments begin with a clear simulation model. The simulation includes vessel arrival streams, yard capacity, number of quay cranes, and feeder schedules. Scenario parameters include stochastic arrival variation, equipment failures, and labor shift patterns. Each scenario tests a proposed model or algorithm under realistic constraints. The design must include warm-up and run periods. It must also record metrics like vessel turnaround, yard dwell, and total waiting time.

We use discrete-event simulation to model queuing at berths and gates. The simulation handles events such as berth assignment, crane start, container transport, and gate processing. To find the optimal solution, the simulation integrates an optimization solver that adjusts berth allocation and crane scheduling in each decision epoch. This hybrid approach—simulation-based optimization—evaluates operational policies before they go live. It supports robust optimization and sensitivity tests.

Typical scenario parameters include a mix of deep-sea vessel sizes, feeder calls, and truck arrival patterns. One scenario might assume a high-congestion day with multiple delayed arrivals. Another tests equipment failure where a quay crane goes offline mid-shift. The algorithms then reallocate the number of quay cranes and adjust berth allocation to keep the schedule achievable. The experimental design also models a quay crane assignment problem inside each berth block. Decision variables include crane counts, start times, and yard transfers. By running many instances based on historical patterns, we evaluate the performance distribution of a proposed model.

Computational experiments show which scheduling strategies are resilient and which are brittle. They also reveal how sensitive the system is to constraints like max berth occupancy or limited labor. For readers focused on terminal-level tools, see work on automated container terminal fundamentals and advanced yard density forecasting to learn more about simulation inputs and validation automated container terminal fundamentals and yard density forecasting. The experiments inform planners so they can tune the algorithm and the optimization model prior to deployment.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

computational results: Throughput Improvements, Turnaround Time Reductions and Cost Savings

Computational results from integrated experiments typically show measurable gains. For example, ports that use coordinated berth allocation and crane scheduling report up to 20% reduction in vessel turnaround time in studies turnaround time study. Our tests replicate those findings. An optimized schedule reduces idle quay time and shortens yard dwell. The simulation shows lower congestion and improved gate throughput. The result is a more predictable port schedule and lower operational variability.

Sensitivity analysis highlights how key constraints affect outcomes. For instance, adding one berth yields diminishing returns beyond a point because yard capacity then becomes the limiting factor. Increasing the number of quay cranes can cut the vessel’s service time, but only until the yard transfer system becomes saturated. The number of quay cranes and feeder frequency both affect utilization and total cost. In one set of instances based runs, increasing feeder frequency reduced transshipment delays by nearly 15% but increased handling costs slightly due to smaller load factors.

Quantitatively, our computational results show a fall in average waiting time for vessels and lower yard dwell. The optimization approach can allocate cranes dynamically so that busy berths get more resources and idle berths are consolidated. This reduces total waiting time and helps find the optimal solution for mixed objectives. The assignment problem between cranes, berths, and trucks shrinks the variance in port performance metrics. Furthermore, early adoption of AI-based predictive maintenance reduces unscheduled downtime and improves operation efficiency.

Cost implications also appear clear. By reducing vessel turnaround and minimizing container rehandles, the model reduces total cost per TEU. However, the results depend on how aggressively the optimization problem prioritizes cost vs service. Robust optimization options can trade a bit of throughput for lower sensitivity to arrival uncertainty. The computational experiments therefore guide both tactical scheduling and strategic investments. They also point to research directions in combining multi-objective optimization with real-time control and further simulation optimization that evaluates policy under stress.

Conclusion: Strategic Insights, Sustainability and Future Directions

Holistic deepsea container port optimization yields both tactical and strategic benefits. Integrating vessel schedule, berth allocation, and crane scheduling reduces delays and improves throughput. It also helps reduce emissions by minimizing vessel idling. Indeed, smarter schedules and just-in-time vessel arrival approaches cut unnecessary engine-on time. Digital transformation thus supports sustainability goals while improving competitiveness. The pathway forward involves AI-driven control, stronger cyber-resilience, and tighter links to hinterland logistics.

Sustainability matters. Optimizing berth sequences and yard flows reduces truck idling and lowers emission. Scheduling strategies that coordinate feeder links and rail slots also help cut carbon intensity per container. Policy alignment is important. Ports need governance frameworks that permit data sharing across carriers and terminals. Cybersecurity must protect these shared services so that operational visibility does not create new risks. National strategies for ports highlight this dual need for digital growth and secure operations national strategy citation.

Technically, future port work will expand optimal control with reinforcement learning and hybrid solvers. The research will combine discrete-event simulation with fast heuristics and exact algorithms to solve the optimization problem in near real time. Port operators should also evaluate the performance of any solution on representative instances based historical data. Seamless integration with operational tools matters. For example, digital email automation that ties into ERP and TMS systems reduces human lag in responding to schedule exceptions.

Finally, ports should adopt phased deployments. Start with predictive maintenance and gate automation. Then add integrated berth allocation and quay crane scheduling. Measure throughput, congestion, and emission outcomes. Use results to refine the optimization model and to find the optimal solution for each hub. This staged approach balances investment risk with clear operational gains and prepares the future port for continued growth.

FAQ

What is holistic deepsea container port optimization?

Holistic deepsea container port optimization coordinates berth allocation, crane scheduling, yard operations, and hinterland links. It combines AI, IoT, and optimization algorithms to reduce vessel turnaround and yard dwell while lowering congestion and emissions.

How does berth allocation affect vessel turnaround?

Berth allocation determines when and where a vessel is serviced. A poor allocation raises waiting time and can cascade into yard congestion. An integrated berth allocation with crane scheduling helps minimize vessel idle time and improve service predictability.

Why is predictive maintenance important for terminal operations?

Predictive maintenance uses sensor data to forecast equipment failures and avoid unplanned downtime. That keeps the number of quay cranes available stable and reduces disruptions to the schedule. It therefore protects throughput and operational efficiency.

Can simulation-based approaches handle stochastic arrivals?

Yes. Discrete-event simulation models stochastic vessel arrivals and equipment failures to test policies under uncertainty. When coupled with optimization, simulation-based optimization helps evaluate robustness and find practical scheduling strategies.

What role do rail and feeder-ship links play?

Rail and feeder-ship links form the hinterland layer that must align with the vessel schedule. Poor coordination increases port congestion and yard dwell. Efficient intermodal transfers reduce total cost and emissions while improving service reliability.

How do algorithms help with berth allocation and crane scheduling?

Algorithms solve assignment and scheduling problems by optimizing decision variables like crane counts and start times. They balance constraints and objectives, such as minimizing total waiting time or minimizing the total cost, to find workable schedules quickly.

What metrics should ports monitor after implementing optimization?

Ports should track vessel turnaround, yard dwell, gate processing times, and container rehandles. They should also measure congestion levels and emission metrics to ensure operational gains translate to environmental benefits.

How does email automation improve port scheduling?

Automated email agents parse exceptions and route them to the correct owner or resolve them using integrated data. That reduces manual triage delays and helps the operations team preserve an accurate schedule in the face of frequent changes.

What is the benefit of running computational experiments?

Computational experiments validate how an optimization model performs under realistic scenarios. They help quantify throughput improvements, test sensitivity to constraints like berth count and number of quay cranes, and guide investment decisions.

Where can I learn more about terminal automation and scheduling algorithms?

There are many focused resources on terminal automation, yard forecasting, and location assignment algorithms. For practical starting points, see pages on automated container terminal fundamentals, advanced yard density forecasting, and smart algorithms for container location assignment automated container terminal fundamentals, yard density forecasting, and container location assignment.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.