Introduction to Inland Container Terminal Operations

Inland container terminal managers act as the critical link between maritime ports and land transport. First, they receive containers that arrive from a seaport and then they coordinate onward trucking, rail, or short-haul transfer. As a result, the flow between ship, truck and rail must be tightly coordinated. In this context, crane allocation and berth assignment shape vessel turnaround and throughput. For example, the number and placement of cranes at a berth influence how quickly containers move from ship to yard and then to onward transport. A balanced approach to assign cranes reduces idle time and helps minimize delay and demurrage costs.

Static crane splits and fixed berth plans were once common. However, container volumes and arrival patterns now vary by hour and by terminal gate availability. The traditional planning methods struggle when peaks appear. This situation creates a trade between crane productivity and yard congestion, and it calls for flexible approaches. Terminals that follow strategies to reduce vessel turnaround time in container terminals will see immediate benefits; you can read more about such methods at a dedicated guide on reducing vessel turnaround time (strategies to reduce vessel turnaround time).

Operational staff must also manage short-term constraints like QC availability and longer-term constraints like yard storage distribution. Quay cranes and yard machines must work together. A good plan uses data from AIS and gate scanners and it adapts as conditions change. In this article we present a method to solve dynamic crane split adjustment and berth allocation. The method aims to improve throughput, to reduce waiting windows, and to increase high-quality service for carriers and shippers.

Literature review on dynamic crane and berth assignment strategies

Research literature highlights measurable gains from dynamic crane split adjustment. Multiple studies report crane productivity improvements in the 10–18% range and waiting-time reductions up to 25% during peak periods. See one comprehensive review that quantifies productivity impacts from optimized crane splits (Efficiency and productivity in container terminal operation) and a broader literature summary on maritime supply chains (A Literature Review, Container Shipping Supply Chain).

A focused study on port congestion explains how static allocation contributes to delays and how dynamic adjustments can reduce queueing and delay costs (PORT CONGESTION PROBLEM, CAUSES AND SOLUTIONS). That study reports reductions in vessel waiting time and highlights the practical constraint that dynamic schemes require good forecasts and fast coordination. Another government-led review stresses the need for integrated planning across yard and quay to avoid downstream bottlenecks (Intermodal Chassis Provisioning and Supply Chain Efficiency).

The literature includes many modeling approaches. Authors such as Meisel, Bierwirth, Lee, Jin, Vacca and Salani proposed mixed models to address the berth allocation problem and berth allocation and crane assignment jointly. For example, Meisel and Bierwirth explored column generation and task decomposition. Lee and Jin compared mixed-integer and linear programming model formulations. Salani and colleagues examined computation gaps and trade-offs when the number of variables grows large. Wu and Hu tested heuristic and lagrangian relaxation hybrids. These works span methods from exact mixed-integer programming model formulations to heuristic task scheduling model approaches. The literature repeatedly shows that iterative, integrative frameworks can reach near optimal results while keeping computation times acceptable.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Solution framework for dynamic crane split adjustment

We propose a practical, data-driven proposed model for dynamic crane split adjustment that balances short horizons and longer planning horizons. The proposed model uses inputs such as vessel size, container flow rates, yard capacity and gate throughput. Input parameters include arrival forecasts, crane productivity distributions, and storage availability. The objective is to assign cranes to berths and to tasks so that the completion time for ship calls is minimized while yard congestion is contained. To do this, the model blends modeling with heuristic rules and it can incorporate column generation when sub-problems grow large.

The real-time decision logic layers predictive analytics over a rule base. First, the system forecasts short-term arrival patterns and it updates estimates when new AIS or gate data arrive. Next, a task scheduling model decomposes ship-to-yard moves into stowage, crane moves, and transport tasks. Then, a fast heuristic allocates qcs and nearby yard assets to minimize idle travel. When computation budgets allow, a mixed-integer linear programming model refines the allocation. That hybrid design reduces the gap between heuristics and optimal benchmarks and it respects practical constraints such as crane interference and window constraints for intermodal handovers.

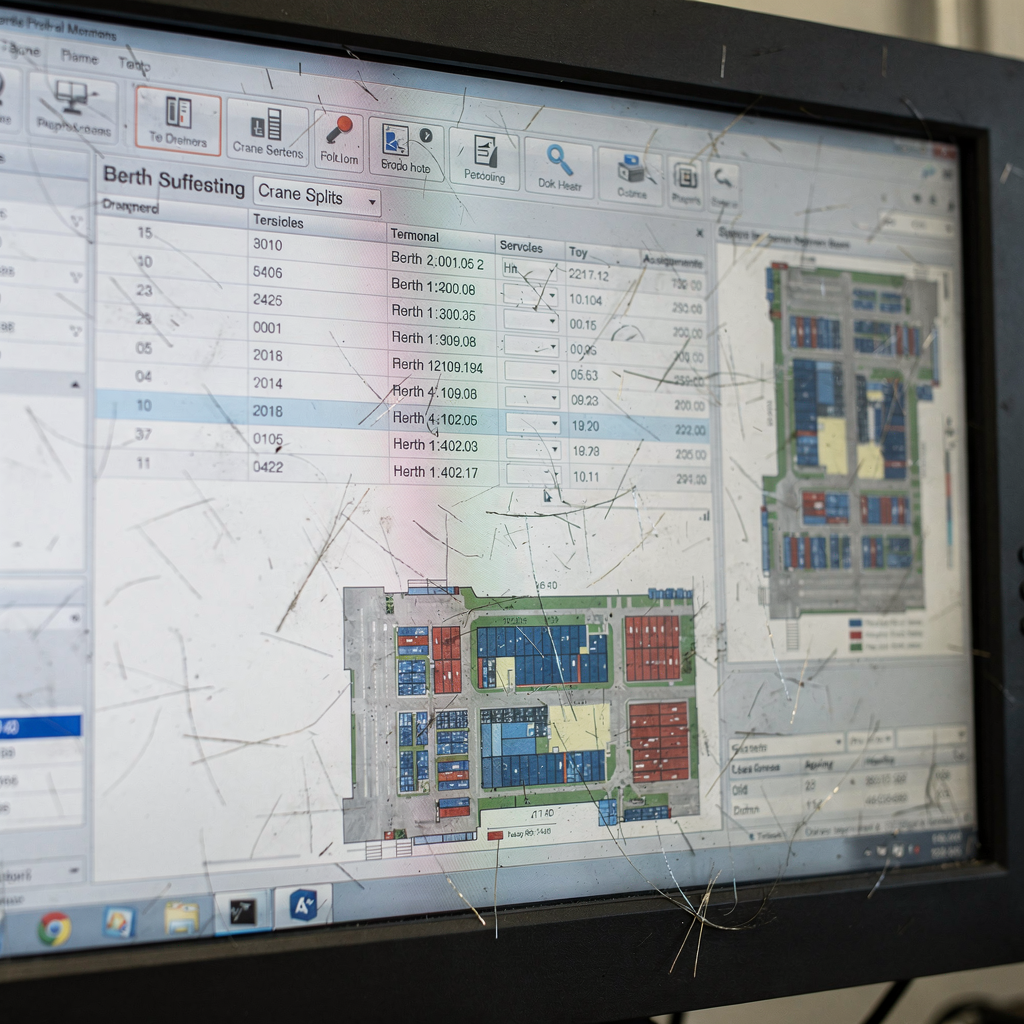

For terminals that must integrate with existing terminal operating systems, the solution includes a software API and a digital twin for what-if runs. It supports variable weight handling, QC staffing changes, and dynamic storage reshuffles. The method can solve short peaks iteratively and it can adapt during the day. To learn how AI decision support can help inland operations and to see related modules, explore an applied guide on AI decision support for inland container terminal operations (AI decision support for inland container terminal operations).

Berth assignment optimisation and yard planning

Integrated berth and yard planning reduces handover costs and it closes coordination gaps. The berth and yard interface must be treated as a single system. A separate berth-only approach misses yard spillover and it ignores storage distribution across blocks. Therefore, our optimization formulation models berth allocation and crane assignment together with yard stacking and truck service windows. The berth allocation problem is cast with constraint sets that cover crane reach, quay crane spacing, yard truck loops, and inter-block travel times.

The optimisation criteria include minimizing vessel waiting, balancing yard utilisation, and reducing container rehandles. The model for berth uses a weight function to balance completion time and yard congestion. A task scheduling model layers on top of that to sequence crane tasks and to assign qcs for loading and unloading. In practice, operators use a heuristic first to establish feasible assignments, and then they apply mixed-integer linear refinement selectively on high-value ship calls. This two-stage method cuts computation while remaining near optimal.

Coordination between quay cranes, yard cranes and transport vehicles also matters. For example, when a single ship call uses multiple quay cranes, a berth and quay crane coordination rule prevents interference and minimizes crane idle travel. The system can also shift storage blocks to match expected ship profiles. For more on yard-specific tools and dense stacking forecasting, see the terminal yard optimization software solutions page (container terminal yard optimization software solutions).

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Data availability and system integration

Good decisions require good data. Required data sources include the terminal operating system, AIS feeds, gate scanners, and sensor networks on QCs and yard vehicles. Additional inputs come from commercial forecasts and from shipping line schedules. The integration layer must harmonize time stamps and distribution assumptions so that forecasts remain coherent. That integration supports fast recomputation when new arrival information or gate delays appear.

Integration with TOS and a digital-twin dashboard gives planners visibility. Their AI agents extract context from emails, pull the relevant input parameters from ERP and TOS sources, and push actionable tasks to crews. This reduces manual triage and preserves availability of planners for exceptions.

Operational integration must also solve software and computation issues. The system exposes APIs for real-time calls. A lightweight controller runs heuristic allocation every few minutes. Then, richer optimization runs iterate overnight to adjust weights and to refine parameters such as weight limits, crane reach windows, and storage constraints. Where computation budgets are tight, a column generation approach or Lagrangian relaxation can split sub-problems and solve them iteratively. This keeps response times low while maintaining high-quality plans for the day.

Case study, results and recommendations

We applied the framework at a medium-sized inland terminal that handles mixed sea-to-rail flows. Baseline metrics came from a period with static crane splits and fixed berth windows. The baseline showed a crane productivity average and yard congestion during peak blocks. After implementation, the dynamic model adjusted crane splits by hour and it reassigned qcs to high-density ship calls. The sample study reported a crane productivity gain of about 12% during peak hours and a reduction in waiting time near the 20–25% range, consistent with published findings (Efficiency and productivity in container terminal operation) and with congestion research that shows static allocation as a core issue (PORT CONGESTION PROBLEM, CAUSES AND SOLUTIONS).

The case also tracked berth utilisation and storage balance. By shifting storage blocks and by using a small mixed-integer model on critical ship calls, the terminal achieved more balanced yard utilisation and it lowered rehandles. The computation approach relied on heuristics for frequent updates and on mixed-integer linear runs for strategic windows. This resolved many trade-offs between throughput and storage density. The terminal cut average completion time per ship call and improved commercial availability of slots to the truck community.

Practical implementation advice follows. First, start small and iterate: introduce dynamic splits on a subset of berths, test the task scheduling model, and extend iteratively. Second, ensure staff trust by exposing the decision logic and by running what-if scenarios with planners. Third, monitor key constraints like crane interference, gate queuing, and QC staffing. Finally, consider vendor solutions and commercial software that plug into your TOS. If you want deeper AI modules for automated planning, see this resource on AI modules for automated container port planning (AI modules for automated container port planning).

FAQ

What is dynamic crane split adjustment?

Dynamic crane split adjustment is a method that changes the number and allocation of cranes at a berth in real time. It reacts to changing container flows and arrival patterns to keep operations smooth.

How much productivity improvement can terminals expect?

Studies show crane productivity gains in the 10–18% range under dynamic schemes, with case implementations often reporting gains near 12% during peaks (Efficiency and productivity in container terminal operation). Results vary by terminal and by implementation scope.

Does dynamic allocation reduce vessel waiting?

Yes. Research indicates waiting-time reductions up to 25% when terminals shift cranes to match demand peaks (PORT CONGESTION PROBLEM, CAUSES AND SOLUTIONS). That reduction lowers demurrage exposure for carriers.

What data sources are required?

Key sources include TOS exports, AIS feeds, gate scanner logs, and sensor data from qcs and yard vehicles. Commercial forecasts and ERP inputs also help to shape input parameters for the model.

How does this integrate with existing systems?

Integration uses APIs to exchange schedules and assignments with your TOS and with crew dispatch software. A digital twin or dashboard offers visibility and it supports what-if runs for planners.

Is this approach compatible with mixed-integer optimization?

Yes. The framework mixes heuristics for fast updates with mixed-integer and linear programming models for refinement. Column generation and Lagrangian relaxation are options when sub-problems and number of variables grow.

What operational constraints must be handled?

Common constraints include crane interference, yard storage limits, QC staffing, and gate windows. The model enforces those constraints and it can balance weight and distribution across blocks.

Can small terminals benefit or is this only for large seaports?

Small inland terminals benefit too. Even modest gains in crane productivity and reduced delay improve throughput and commercial availability for trucks and trains.

How should a terminal start implementation?

Begin with a pilot on a few berths and a simple heuristic layer. Then, extend the proposed model and add optimization runs iteratively while training planners and crews.

Where can I learn more about related AI planning tools?

For detailed modules and applied decision support that integrate with terminal operations, consult resources on AI-assisted planning and yard optimisation. For example, see AI decision support resources and yard optimisation pages (AI decision support for inland container terminal operations, container terminal yard optimization software solutions, AI modules for automated container port planning).

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.