Problem description of stowage planning in container terminals

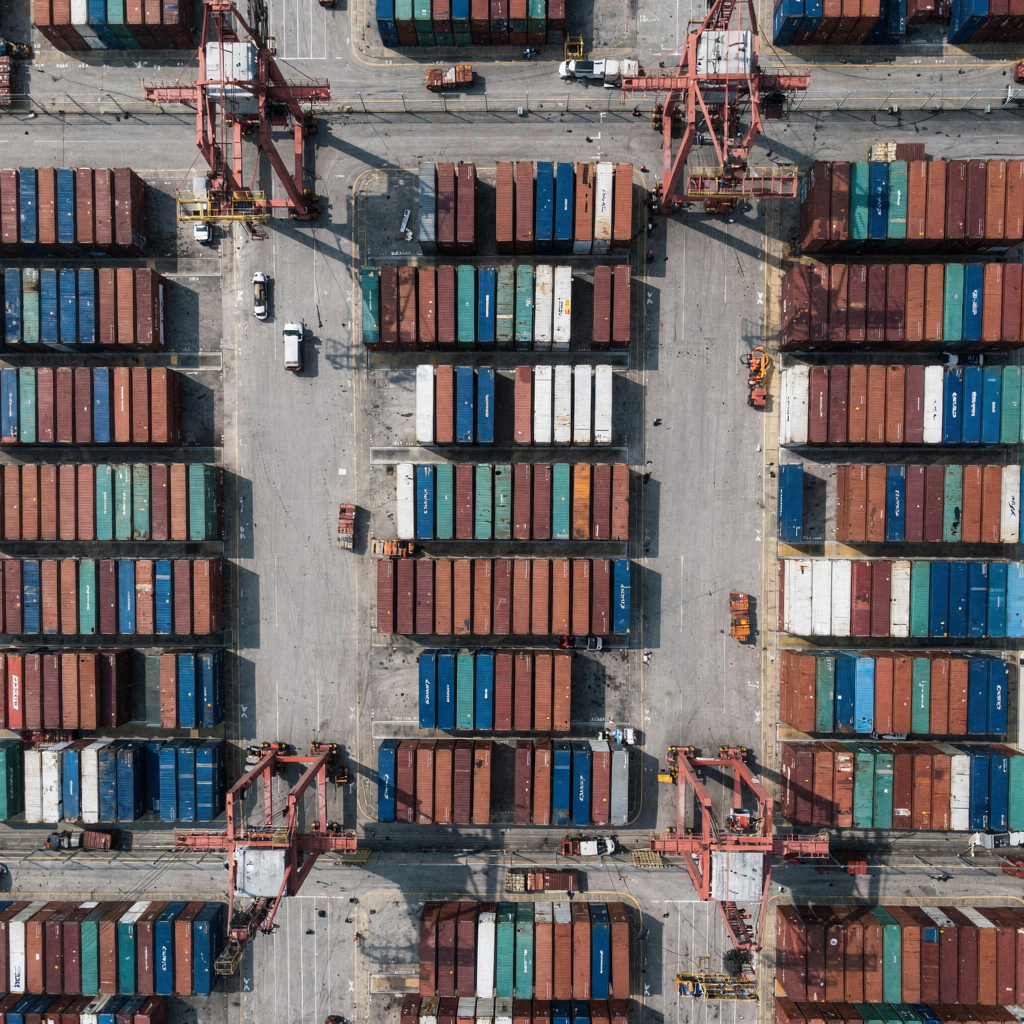

Stowage planning assigns containers to slots so a vessel sails safely and terminals operate smoothly. At its core, stowage balances vessel stability, weight distribution and port efficiency. Planners must consider the arrangement of containers on decks and in holds so the ship stays within stability limits and cranes can load and unload efficiently. The problem description often frames this as a multi-objective job: preserve balance, reduce container rehandling and speed up unloading and loading.

Key constraint categories shape the plan. Weight and center of gravity drive trim decisions, while destination clusters affect sequencing for unloading. Handling equipment availability, such as yard cranes and quay crane schedules, limits what can be executed in a given window. Planners also factor in constraints of the container, like hazardous cargo rules, special lifting needs and size classes. In research, people model these trade-offs with mathematical and binary linear programming, and with pragmatic rules used on the gate and in the yard.

Operational impact appears in measurable KPIs. Poor plans increase container rehandling and reduce throughput at the seaport container terminal. Conversely, a good plan reduces vessel turnaround time and increases moves per hour. A storage location assignment can influence truck waiting times and yard congestion. For a single bay or across the whole containership, the objective of minimizing unnecessary moves matters. Studies show that smart software can cut idle crane time and reduce rehandling, so shipping companies and port operators take notice. For example, McKinsey estimates that advanced tools can improve stowage efficiency and reduce idle time by up to 20% (McKinsey).

Academic methods range from integer programming models to heuristic search. The storage location assignment problem and storage space limits make the plan problem difficult to solve. Many texts reference NP-HARD formulations and propose branch and bound, integer programming, and simulation model approaches. Practical port teams prefer fast, reliable plans that keep containers within reach of quay cranes and yard cranes and that reduce the number of shifts spent firefighting. For more fundamentals on how vessels are planned in terminals, see our guide to stowage planning fundamentals for port operations.

Algorithm: predictive analytics approach

Predictive analytics in stowage planning uses data to forecast arrivals, equipment status and yard flows. Teams feed historical and real-time feeds into models. Then the models recommend slot assignments and sequences that meet multiple goals. This model based approach blends regression, decision trees and neural networks so planners can forecast container arrival windows and probable outbound containers per call. In many cases the models run as part of a larger system that integrates with a TOS. For terminals that need deeper coverage, companies can follow research on model based scheduling and optimization problems.

Machine learning techniques offer dynamic slot assignment and sequence recommendations. For example, regression helps estimate dwell time and probability of outbound containers, while decision-tree ensembles classify containers by handling priority. Neural networks, trained on sensor and telemetry streams, learn subtle patterns in yard flow. Some teams even wrap these predictors into an integer programming model or into reinforcement learning agents to generate executable plans. At Loadmaster.ai we use RL agents to train policies in a digital twin so the AI does not just imitate past practice but seeks improved policies over millions of simulated moves. This approach can be cold-start ready and avoids the need for pristine historical data.

Quantitative benefits appear compelling. Implementations with predictive capabilities reportedly cut vessel idle time by up to 20% and reduce container rehandling by around 15%, which in turn boosts throughput and lowers costs (McKinsey, whitepaper). As the whitepaper states, “Predictive analytics enables terminals to move from reactive to proactive planning, significantly enhancing operational resilience and efficiency” (shipzero).

This approach demands good data and compute. Teams need clean manifests, feeder schedules, crane telemetry and yard status. Computational time can grow when many objectives are included. On the other hand, predictive analytics adapts as new conditions evolve. It can handle complex constraints and multi-objective trade-offs such as throughput versus yard congestion and quay productivity. For readers who want to understand how AI meets vessel planning, our piece on AI-assisted vessel planning for shortsea container terminals explains practical integration paths.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Heuristic: rule-based methods for stowage planning

Heuristic approaches use rules and experience to make quick stowage choices. Simple guidelines include destination clustering, weight-based grouping and sequence-based loading. Planners often rely on these rules when data are sparse or when decisions must happen quickly. Heuristics provide robust baseline plans that are easy to audit and to execute under the pressure of tight berthing windows.

Typical heuristic tactics include stacking export containers by port of discharge and grouping heavy cargo to preserve trim. A greedy placement rule can put the highest-priority container in the nearest available slot. Meanwhile, rule sets can enforce master bay limits and maintain access lanes for cranes. These methods require minimal data: a manifest, a crane schedule and a basic yard state. Because of the minimal inputs, heuristics produce a stowage plan in seconds, which suits time-critical contexts at the port and at busy container ports.

Research confirms that heuristics often reach near-optimal solutions quickly. For example, literature on container shipping supply chain planning notes that heuristic methods can complete plans in seconds and save computation relative to exhaustive search (literature review). However, that speed comes with trade-offs. Heuristic approaches may be 5–10% less efficient than predictive, data-driven methods in terms of rehandling and space use (TUHH research).

Heuristics shine when planners need to reduce the number of shifts spent firefighting and when data quality is poor. They also work well as fallback logic when computational resources fail. Yet heuristics struggle to adapt to real-time disruptions. They can’t predict equipment failures or learning patterns that affect outbound containers. For complex scheduling problems that involve sequencing of quay cranes and yard cranes, planners often combine heuristics with more advanced models to get a faster starting point and then refine it.

Heuristic algorithm: strengths and limitations

Practical heuristic algorithms include greedy placement, tabu search variants and heuristics based on genetic operators. A based on genetic approach may hybridize rules and mutation-like moves to improve arrangements of containers across bays. In many papers, researchers compare greedy rules to more advanced genetic algorithm methods and to mathematical programming models. For instance, a genetic algorithm can explore non-intuitive stacking patterns while keeping computation tractable for medium-sized problems.

Advantages are clear. Heuristic algorithms require little computing power and run fast on modest hardware. They are robust under poor data quality and they support quick decision loops for yard operation. Port crews can apply a heuristic and keep cranes working without waiting for long computation cycles. In tight windows, when unloading and loading must happen within hours, heuristics preserve throughput and maintain predictable execution.

Still, drawbacks limit their use. Static rules lack the adaptability needed during major disruptions or when a containership faces unexpected stowage changes. Heuristics often yield sub-optimal space utilization and higher container rehandling. In academic tests the difference may be 5–10% in rehandling rates compared to predictive solutions. Also, heuristics can miss subtle correlations that a model captures, such as how yard congestion in one block affects downstream retrieval times.

Researchers use examples from the literature, such as branch and bound studies and integer programming model baselines, to show where heuristics fall short. Studies by authors like Avriel and Ambrosino et al provide formal analyses and comparisons. For readers interested in algorithmic foundations, methods in the literature range from binary linear programming to tabu search and include references to authors such as avriel, avriel et al, ambrosino, ambrosino et al, zhang and zhang et al. To see how heuristics can form part of a larger automation stack, consult our article on TOS-agnostic software plugins for terminal operations.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Comparative analysis of predictive analytics algorithm and heuristic algorithm

Accuracy and adaptability separate the two approaches. Predictive methods adjust as new data arrive and they can solve complex multi-objective trade-offs. Heuristics follow rules and deliver consistent, explainable outcomes. For planners the trade-off often comes down to how much time they have and how clean their data are.

Computational time differs widely. Predictive pipelines need training time and may require substantial computation during inference for large combinatorial problems. Heuristics, by contrast, produce near-instant plans. Where computational resources are limited, heuristics remain attractive. Where terminals invest in compute, predictive analytics can improve operational efficiency and reduce container rehandling, raising throughput.

Data requirements also vary. Predictive analytics demands big, high-quality datasets and telemetry inputs. Heuristics work with basic manifests and yard snapshots. Yet hybrid workflows prove valuable in practice. Teams often generate an initial heuristic plan and then refine it using a model based optimizer. This hybrid idea matches research and practice. McKinsey and other sources recommend combining fast heuristics with advanced software to capture both speed and better outcomes (McKinsey).

Operational impact depends on the terminal. In deepsea container terminals, optimizing quay schedules and yard routing can change the economics of a call. Reinforcement learning agents can produce policies that reduce driving distances and balance crane workload. At Loadmaster.ai we train agents in a simulation and then validate with live telemetry, which reduces the need to retrieve perfect historical data. Our approach addresses problems from scheduling of quay cranes to retrieving containers in a way that preserves execution guardrails. For more on integrating AI into port operations, read our piece on AI in port operations: stowage planning.

Integration and future prospects

Modern terminals blend heuristics and predictive analytics to get the best of both worlds. A common pattern uses a heuristic to create an initial plan and then a model to refine that plan. This hybrid workflow combines speed and optimality. It reduces computation time while improving outcomes. Hybrid systems also support guardrails so planners can accept model proposals with confidence.

Emerging trends point toward intelligent stowage driven by AI and digital twins. Reinforcement learning, simulation model training and intelligent optimization enable policies that adapt online. Digital twins let teams test proposed algorithm based policies against realistic scenarios. For terminals that want to minimize risk, simulation lets teams verify plans before live rollout. At Loadmaster.ai, RL agents learn in a sandbox and then operate within explainable KPIs, avoiding the need to train on flawed historical records.

Research directions include real-time sensor integration and collaborative models across multiple terminals. Integrating berth allocation and the scheduling of quay cranes with stowage choices creates new opportunities. Work on storage location assignment problems and on simulation model fidelity will improve the quality of decisions. Papers by scholars like Sciomachen and Bazzazi et al explore simulation and optimization approaches. Other authors such as Tanfani examine yard operation specifics and sequencing challenges.

Policy and technical challenges remain. Many of the optimization problems are discrete and NP-HARD, which makes exact solutions impractical at scale. However, hybrid methods, genetic algorithm variants, and branch and bound heuristics provide feasible paths. Future research directions include reinforcement learning for continuous improvement, collaborative planning across container terminals, and tighter integration with TOS via APIs to manage latency and data consistency. For terminals seeking reduction in crane idle time or in empty driving, practical integrations exist and pilots can show measurable gains in throughput and in minimize the number of shifts spent firefighting. See our article on reducing deepsea container port equipment idle time for practical tactics (reducing deepsea container port equipment idle time).

FAQ

What is stowage planning and why does it matter?

Stowage planning assigns containers to positions on a vessel so the ship stays balanced and loading and unloading run smoothly. Good planning reduces container rehandling, shortens vessel turnaround, and increases terminal throughput.

How do predictive analytics models improve stowage plans?

Predictive models use historical and live data to forecast arrivals and equipment availability, then suggest dynamic slot assignments. They can reduce idle time and cut rehandling by learning patterns and adjusting plans proactively.

When are heuristic methods preferable?

Heuristics suit time-critical cases or when data quality is poor. They run fast, require minimal computation, and give planners dependable baseline plans that they can execute immediately.

What is a heuristic algorithm in the context of terminals?

A heuristic algorithm uses rule-based logic or search shortcuts to place containers quickly, such as greedy placement or tabu search variants. These methods trade some optimality for speed and simplicity.

Can predictive analytics and heuristics work together?

Yes. Terminals often use heuristics to create initial plans and then refine them with predictive or model based optimizers. This hybrid flow balances speed and solution quality.

What role does simulation play in modern stowage planning?

Simulation models and digital twins let teams test proposed strategies safely. They provide training environments for reinforcement learning and help validate plans before live deployment.

How does Loadmaster.ai approach stowage planning differently?

Loadmaster.ai trains reinforcement learning agents in a digital twin, which avoids reliance on historical data and finds multi-objective policies. The system focuses on executable KPIs and integration with TOS systems for safe rollouts.

Are these methods suitable for all container terminals?

Suitability depends on terminal size, data availability and operational priorities. Smaller terminals may prefer heuristics, while larger, data-rich operations benefit from predictive and RL approaches. Hybrid approaches can work across scales.

What are common constraints planners must handle?

Planners must manage weight, vessel trim, hazardous cargo rules, handling equipment schedules and space limits. These constraints shape feasible plans and influence crane sequencing and yard moves.

Where can I read more about implementing AI in port operations?

Start with practical guides and case studies on AI-assisted vessel planning and on AI in port operations. Loadmaster.ai also offers resources on TOS-agnostic plugins and on reducing equipment idle time for container ports.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.