latest news

AI in port operations stowage planning

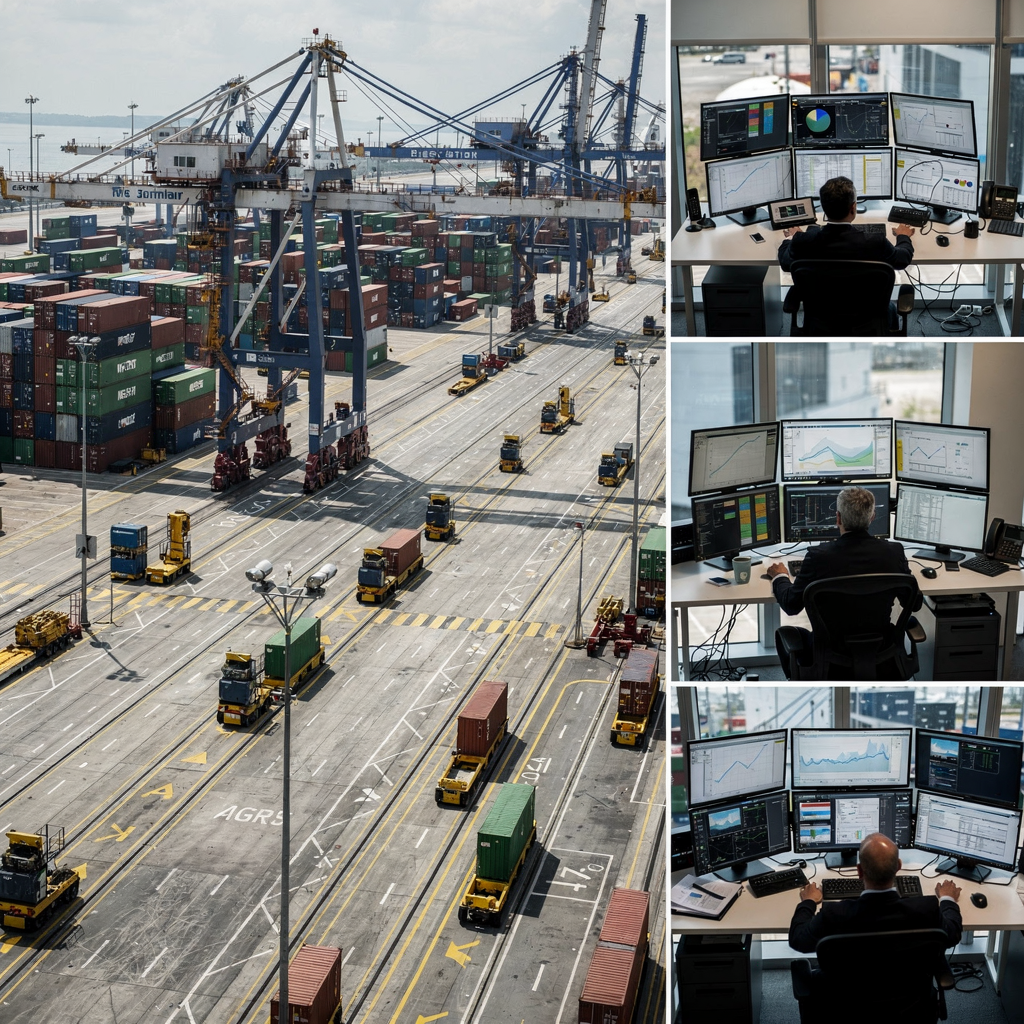

AI and Machine Learning in Port Operations AI and machine learning are reshaping how terminals plan cargo and run operations. First, AI gives terminals models that learn patterns in vessel arrivals, cargo types, and yard capacity. Second, machine learning improves predictions about berth timing and resource needs. Third, these tools help determine the most efficient […]

Predictive maintenance at container terminals with AI

Terminal operating systems and analytics: automating anomaly detection Terminal operating systems pull together telemetry from cranes, trucks, reach stackers and yard equipment. They collect sensor streams, transform them, and feed dashboards for terminal operators. For effective predictive maintenance using this telemetry, the terminal operating systems must ingest high-frequency data and present clean, actionable signals. For […]

Container tracking API for terminal latency and consistency

Terminal operations and container tracking api essentials First, define what matters at a terminal when you expect fast, consistent data. Terminal operations depend on clear latency thresholds and strict data consistency rules. For yard work and gate workflows, many operators set soft latency limits near 200 ms for routine queries and hard limits below 1 […]

Reducing crane idle time in ports with twistlock automation

container terminals and twistlock handling: causes of crane idle time Crane idle time hits container terminals when spreader operations stop and waits stack up. And this pause matters because every minute off the hook pushes ship calls later and raises berth occupancy. A recent technical handbook documents “loss of time due to jammed twistlocks” and […]

Handling special containers in container terminals and ports

Overview of Special Container Types in terminal operations at the port Special container types shape how a port organises flows, space, and equipment. First, refrigerated (reefer) containers keep perishable goods cool and require powered plug points and continuous monitoring. Second, hazardous materials containers carry regulated substances and demand segregation, dedicated handling zones, and written procedures. […]

Container lashing plan and weight calculation

container stowage fundamentals in maritime logistics Container stowage refers to the planned placement of containers on a vessel to protect safety and maintain vessel stability. It involves arranging units by weight, contents, destination, and handling priority. Planners consider centre of gravity, stack patterns, and the interaction between stacks and vessel motions. The arrangement prevents containers […]