Introduction: Role of AI in Modern Container Terminals

AI stands for Artificial Intelligence, and it refers to software that learns, reasons, and acts on data. In modern container terminals, AI helps operators predict congestion, route containers, and schedule equipment. The role of AI in modern container terminals often centers on faster, safer, and more consistent decisions. Ports face intense pressure from rising cargo volumes, tighter schedules, and stricter environmental rules. Deepsea container terminal operations must manage vessel arrivals, yard stacking, gate throughput, and crane cycles every day. That mix creates friction, and so port teams need tools that can reduce friction while keeping operations resilient.

Challenges in deepsea container terminal operations include long vessel queues, unpredictable berth occupancy, variable container dwell time, and fragmented communication between stakeholders. These issues raise costs, increase emissions, and reduce throughput. AI helps by analyzing disparate data streams from sensors, terminal operating systems, and vessel reports. For example, predictive analytics models estimate vessel stay times and delays. One study found that predictive tools can reduce vessel waiting times by up to 20%, and so they directly lower queue length and demurrage risk.

This article gives an overview of AI integration and its strategic importance for port operators and port authorities. It covers trends since 2018, automation use cases, and real-time applications in port management. It also explains how a container terminal operating system can embed advanced AI to deliver measurable port efficiency, and it lists ten AI-driven innovations that transform port operations and efficiency. Readers who want deeper technical detail can explore predictive yard congestion and quay crane productivity resources for guidance. For instance, teams can learn about predictive analytics for yard congestion at this practical guide on predictive analytics for port operations and yard congestion.

By using AI agents that ground replies in ERP and TMS data, teams improve response speed and clarity. This support complements on-dock automation and helps ports coordinate faster across agencies, carriers, and terminal operators. In short, the role of AI extends from equipment control to communications, and it drives better throughput, lower costs, and improved environmental performance.

Trends in AI Integration for Port Operations and Logistics

Since 2018, the adoption of AI across global ports has accelerated. Data shows an increase in projects and pilots that apply AI to vessel scheduling, yard planning, and cargo flows. A review documented an 11% rise in maritime projects utilizing AI, and that trend kept momentum into 2024 as smart port programs expanded across multiple hubs. First, ports began with pilot systems for berth allocation. Next, they integrated sensors and cameras for yard monitoring. Then, they connected stakeholders through digital platforms, and now they focus on scaling AI into daily terminal operations.

AI integration with IoT and big data creates new visibility. Smart port designs fuse data from gate cameras, quay cranes, vessel AIS, and weather feeds. That data feeds ai systems which run analytics and feed control loops. For example, integrating crane logs with yard positions and truck ETA creates a feed that allows ai-powered scheduling to sequence moves more efficiently. Research shows AI-enabled optimization can yield a 15-25% increase in container handling efficiency and a 10-30% reduction in turnaround times in practice.

Impact on logistics workflows is clear. AI reduces manual coordination work, and so ports and terminal operators can coordinate faster with shipping lines and customs. That coordination improves smooth operations, and it also supports sustainability goals. For instance, an ai-driven port queuing system lowered CO2 emissions by about 12% during peak congestion periods in one study. Thus, AI and big data help ports deliver both operational and environmental gains.

Integration of AI has a governance angle. Port community system updates, data-sharing agreements, and cyber security need attention. Still, the potential of AI to transform port management and logistics continues to attract investment. For those building solutions, connecting predictive models to business rules and to existing management systems matters. Readers who want practical tactics for gate throughput and yard efficiency can study container terminal gate optimization explained and inland container terminal yard efficiency improvement techniques for step-by-step practices.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

AI-Powered Automation to Optimize Container Terminal Operations and Port Traffic

AI-powered predictive analytics help ports optimize vessel scheduling and berth allocation. Predictive ai models ingest AIS, weather, and terminal load to forecast arrival and stay times. As a result, terminals can sequence berths and reduce idle crane time. In fact, predictive tools have shown meaningful reductions in vessel waiting times and delays in academic trials. That reduction improves berth utilization and lowers demurrage costs. Next, AI optimizes resource pools by forecasting crane demand and truck flows. So planners can allocate labor and equipment where they will be most effective.

Automation extends to yard handling and gate operations. Automated guided vehicles, remote cranes, and yard planning algorithms combine to shorten container dwell time. AI models predict yard density and prompt dynamic slot moves to avoid bottlenecks. When terminals automate container matching and stowage replanning, they reduce unnecessary container moves and speed up quay cycles. Concrete approaches to improve yard performance include dynamic equipment pool allocation and predictive models for yard density; these practices help ports move from reactive to proactive operations.

Case studies show clear benefits. One deepsea hub reduced port traffic congestion by applying multi-vessel crane scheduling and smart gate sequencing. That pilot improved quay crane productivity and cut truck wait times. For more on practical crane improvements, see optimizing quay crane productivity in container terminals. Applied AI algorithms sequence multiple vessel cranes to avoid idle time and to smooth crane handovers. Moreover, AI can recommend pre-staging plans for peak windows, and so truck throughput rises without adding space.

Terminal operations gain when AI connects to TOS and to a port community system. Then carriers and customs see accurate ETAs, and trucks receive precise pickup windows. That coordination reduces the frequency of missed moves. Understanding intent, routing messages, and drafting accurate replies reduces manual triage and supports faster decisions on the quay and in the yard. Overall, AI helps ports optimize traffic, manage congestion, and improve service for shipping lines and haulers.

Real-Time Application of AI in Container Terminals for Port Management and Cargo Handling

Real-time monitoring systems are central to modern port management. Sensors and cameras stream data to AI systems for instant analysis. The term real-time appears repeatedly for a reason. Operators must react quickly to vessel delays, crane faults, or sudden weather changes. AI in real-time flags anomalies and triggers alerts so teams act sooner. For safety, ai-powered monitoring detects risky movements or equipment malfunctions and sends immediate warnings. That capability reduces accident risk and supports compliance with safety protocols.

Application of AI in container terminals includes anomaly detection, safety alerts, and automated exception handling. Machine learning models learn normal equipment patterns and then detect deviations. When a crane motor shows unusual vibration, the model raises a maintenance ticket. When gate queues exceed thresholds, the system issues dynamic slot offers to inbound trucks. The rapid feedback loop cuts dwell time and improves throughput. In real-time environments, AI models feed decision dashboards and drive automated actions that handle routine events without human intervention.

AI-driven cargo handling optimisation lifts throughput significantly. By optimizing discharge and load sequences, AI optimizes crane moves and minimizes repositioning. Trials indicate increases in container handling efficiency between 15% and 25% when AI tools coordinate quay and yard moves in applied settings. Also, predictive alerts reduce idle time for quay cranes and lower truck turnaround. When ports combine these capabilities with a container terminal operating system, they achieve smooth handoffs across teams and reduce friction across the supply chain.

Real-time systems also enable better stakeholder coordination. Carriers, terminal operators, and customs share status updates instantly. That transparency supports faster inspections and fewer surprises. In practice, real-time integration helps ports meet service level agreements and helps ports keep vessels on schedule. For readers seeking deeper methods, explore automated container terminal stowage replanning software and AI models for deepsea container port yard density prediction to see how real-time modeling ties into higher-level planning.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Container Terminal Operating System (CTOS for Container) for Port Efficiency and Benefits of AI

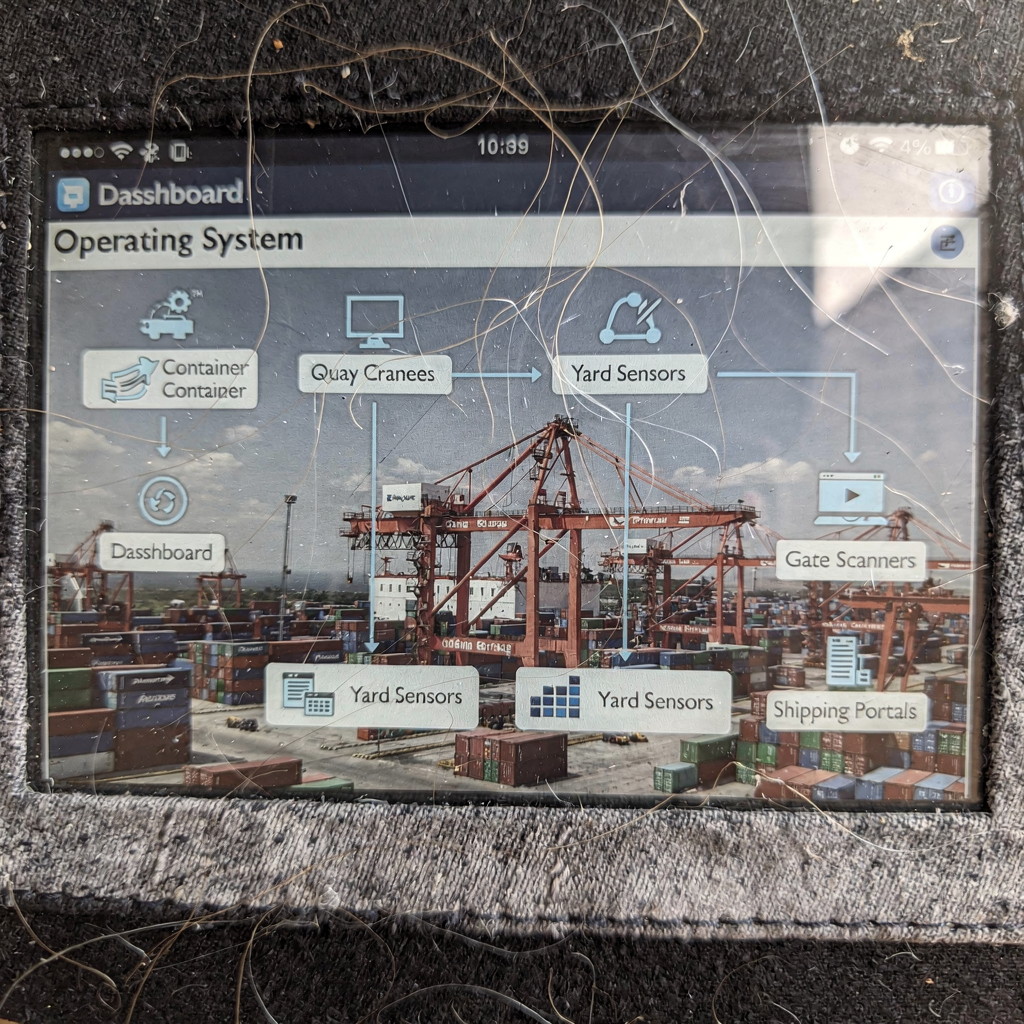

A container terminal operating system is the nervous system of a terminal. A CTOS for container centralizes bookings, yard maps, crane assignments, and gate slots. It interacts with vehicles, cranes, and other management systems. When advanced AI is embedded, the CTOS becomes prescriptive. It recommends moves, sequences work orders, and adapts to live conditions. That architecture reduces manual intervention and supports robust decision-making.

The architecture of a container terminal operating system combines a data layer, a rules engine, and AI models. Data flows in from AIS, TOS logs, camera feeds, and ERP records. The AI layer runs predictive ai and optimization routines, and so it suggests berth windows and yard restow plans. The rules engine enforces safety constraints and business policies. Together, these parts deliver faster cycle times and improved resource allocation. The system often connects to the port community system to share ETAs and to coordinate inspections.

How CTOS for container drives port efficiency is simple to state. CTOS reduces guesswork. It arranges tasks so cranes and trucks face fewer interruptions. It shortens container dwell time and streamlines customs workflows. Quantitative benefits of AI inside a CTOS include reduced turnaround times and lower CO2 emissions. Studies show that AI-driven yard and quay coordination can reduce turnaround by 10–30% and deliver measurable emission cuts, such as a drop in CO2 during peak periods documented in research. That matters for compliance and for cost control.

Port operators should plan implementation of ai carefully. Data quality, change management, and governance are essential. Also, CTOS upgrades must ensure integration of ai with existing port management systems and with customs IT. When implemented ai models are validated and monitored, ports gain consistent performance and predictable outcomes. For hands-on techniques, terminals can refer to dynamic equipment pool allocation and predicting yard congestion in terminal operations to align CTOS actions with real-world demand.

AI Port Solutions: Top 10 Container Terminal Innovations and Application of AI in Container Supply Chains for Port Operators

AI solutions now power many innovations in container terminal workflows. Below are the top 10 container terminal innovations powered by AI. First, predictive berth allocation using ai algorithms. Second, dynamic crane scheduling that minimizes idle time. Third, yard density prediction that reduces unnecessary container moves. Fourth, automated gate triage that speeds truck throughput. Fifth, real-time anomaly detection for safety alerts. Sixth, automated stowage replanning to optimize vessel work. Seventh, energy-efficient job allocation that lowers fuel use. Eighth, AI-driven container matching to reduce handling. Ninth, digital twin simulation for scenario planning. Tenth, AI-enabled communications automation that turns unstructured email into structured tasks.

Application of AI in container supply chains covers end-to-end visibility, from vessel ETAs to last-mile delivery. AI links port events to inland terminals, customs windows, and carrier schedules. That linkage reduces handoff friction across the global supply chain and helps ports and terminal operators respond to disruptions faster. For terminals, leveraging ai for real-time alerts and for predictive capacity planning helps maintain steady throughput. If you want to see technical use-cases, consult reinforcement learning in terminal operations for crane scheduling and multi-vessel crane scheduling optimization for deepsea container ports.

The future role of AI for port operators includes broader autonomy and stronger decision support. AI may recommend staffing changes during peaks. AI may help plan maintenance windows to avoid crane downtime. AI may also enhance compliance by monitoring emissions and suggesting slow-steaming windows. Still, challenges remain: data silos, model governance, and change management. Port authorities and port operators must invest in training, in robust data pipelines, and in cybersecurity.

To transform port operations, teams should start with high-impact pilots, measure outcomes, and scale proven models. In the same way, integrating ai into core TOS and port systems lets teams handle complexity without adding headcount. Finally, ports that embrace AI and that invest in clean data will see measurable benefits: ai reduces waiting time, ai optimizes resource use, and ai is transforming how terminals operate day to day.

FAQ

What is AI-powered port optimization?

AI-powered port optimization uses AI to improve vessel scheduling, yard planning, and equipment allocation. It applies models and automation to reduce delays, lower emissions, and increase throughput.

How does AI reduce vessel waiting times at deepsea ports?

Predictive models forecast arrival times and berth occupancy so terminals schedule work more efficiently. For example, predictive analytics have been shown to reduce vessel waiting times by up to 20% in research.

Can AI improve container handling efficiency?

Yes. Trials report a 15–25% increase in container handling efficiency when AI coordinates quay and yard moves in applied projects. That improvement comes from better sequencing and reduced repositioning.

What role do real-time systems play in port management?

Real-time feeds let AI detect anomalies, send safety alerts, and adjust plans instantly. Real-time visibility shortens reaction time and supports continuous optimization across terminals.

Are there environmental benefits from AI in ports?

Yes. AI-driven queuing and scheduling can cut CO2 emissions during congestion. A study found approximately a 12% reduction in CO2 during peak periods for a port queuing system. That helps ports meet sustainability targets.

What is a container terminal operating system (CTOS for container)?

A CTOS for container centralizes bookings, yard maps, and equipment control. When combined with AI, it prescribes moves and adapts to live conditions, which increases port efficiency and lowers dwell time.

How do ports integrate AI with existing systems?

Integration involves connecting AIS, TOS, ERP, and sensor feeds to AI systems. Ports implement data governance, model validation, and APIs to ensure reliable operations and secure sharing.

Can AI handle communications between stakeholders?

Yes. AI agents can automate emails and ticketing to reduce manual triage.

What are common challenges in implementing AI at ports?

Key challenges include data quality, system integration, governance, and staff training. Addressing these issues requires structured pilots, clear KPIs, and phased rollouts.

Where can I learn more about practical AI techniques for terminals?

Explore resources on predictive analytics for yard congestion, container terminal gate optimization, and quay crane productivity. These guides show tangible steps to implement AI and to measure benefits.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.