Port Operations: Overview and Challenges

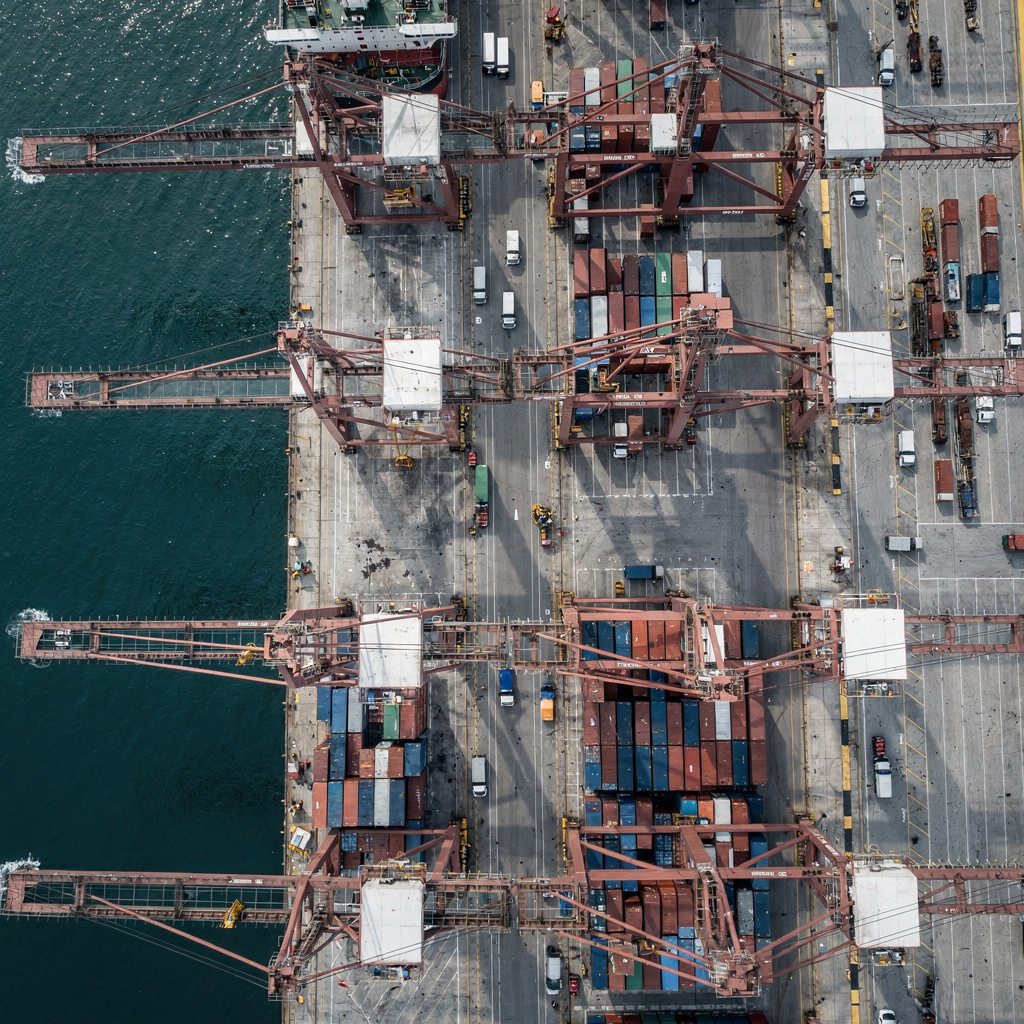

Container terminals sit at the heart of global trade, and they link ships, trucks, and trains into a working supply chain. For a single maritime port the quay is the physical meeting point of many actors, and the decisions made there shape costs and delays. First, planners measure performance with vessel turnaround time, yard throughput, and dwell time. Second, they track crane productivity and berth occupancy. Third, they log waiting time at the quay side and yard side so leaders can improve service for each shipping line. For example, studies show that better sequencing and yard planning can cut turnaround by as much as 15–20% and lift throughput by nearly 12% (systematic review). Also, research ties port congestion to a 10–25% rise in vessel operating costs from extended waits (port performance study).

Common hurdles include yard congestion, crane idling, and peak-period bottlenecks. Planners must manage the allocation of yard slots, container moves, and gate throughput, and they often face a scheduling problem when multiple vessels compete for limited resources. That variability in arrivals creates day-to-day disruption. In practice, firefighting replaces planning when systems lack automation. For instance, yard clash and reshuffling harm productivity, and they increase unnecessary moves and energy consumption. To address this, operators use operations research tools and a mix of heuristics. Then, they combine these methods with a digital twin to simulate scenarios and reduce deviation from plan. In addition, modern terminals integrate data-driven approach layers with TOS systems to improve robustness and reduce rehandles. Loadmaster.ai works in this space, training RL agents inside a digital twin to create policies that balance quay productivity and yard flow, and thus help terminals to minimize crane travel, reduce reshuffling, and stabilize results. Finally, ports that invest in scheduling, berth allocation, and resource planning gain resilience versus those that rely only on historical rules. For deeper technical context see our piece on scalable AI engines for deepsea container port planning (scalable AI engines).

Optimization Strategies in Terminal Logistics

Terminal operations rely on many optimization techniques to handle complexity. In one camp, exact integer programming and mixed-integer linear programming model formulations give provable bounds and clear constraints. In another camp, genetic algorithms, simulated annealing, tabu search, and heuristics offer fast and practical solutions on large instances. For example, researchers document hybrid approaches that pair integer programming with heuristics to get near-optimal solutions within operational time limits (literature review). Also, simulation-based optimization allows planners to test policies before they touch real vessels. When you simulate realistic arrival and yard states, you can observe bottleneck formation and test a scheduling method under stress (simulation-based optimization).

Importantly, integration of simulation with real-time telemetry enables adaptive planning. A data-driven approach that uses real-time input from yard cranes, TOS feeds, and berth sensors lets a model reweight priorities on the fly. Next, integrated algorithms can adjust a discharge sequence when a vessel’s arrival slips. Then, the system recomputes allocation and crane assignments to minimize waiting time and reduce reshuffling. As a result, terminals achieve measurable gains. For instance, applying these methods often leads to up to 20% reduction in turnaround and about 12% higher throughput in numerical experiments. In addition, mixed-integer programming model instances help benchmark new heuristics and reveal trade-offs between crane productivity and yard congestion. Furthermore, Loadmaster.ai builds closed-loop RL agents that learn policies in a digital twin, so the system can propose plans that outperform historical rules while respecting operational constraints. For more on coordinating AI with TOS and workflows see our article on integrating TOS with AI optimization layers (integrating TOS with AI).

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Discharge Sequencing Model for Efficient Unloading

Building a discharge sequencing model starts with clear decision variables. Planners define which container to unload first, where to place it in the yard, and which crane will handle the move. The programming model must include container priority, yard slot coordinates, and expected travel paths. Also, it must model stowage restrictions and safe handling rules. A mixed-integer programming model can capture those rules, while heuristics speed up the plan for day-to-day use. For robust operation, the model treats quay side and yard side costs separately. Then it balances crane cycles, yard cranes, and truck handling to minimize total makespan.

Constraints in the model cover crane availability, stowage plan limits, and yard handling paths. Furthermore, the model enforces safety and container stability rules, and it respects the vessel bay plan and any special cargo needs. To address the allocation problem, the model includes berth allocation windows and resource planning for yard equipment. The optimization objective may aim to minimize vessel’s discharge time, minimize reshuffling, or maximize crane utilization. For example, the optimal sequencing objective can be set to minimize sum of completion times while penalizing restows. A data-driven approach can update the model parameters using short-term forecasts for arrivals and yard occupancy. Also, the model supports hierarchical decision-making where a high-level planner sets goals and a local scheduler enforces equipment constraints. In practice, well-tuned models achieve 15–20% faster discharge and reduce yard congestion by directing moves that avoid future conflicts. For practitioners facing a scheduling problem on busy days, the model can act as a benchmark and a decision aid. See our discussion of container terminal stowage planning and how stowage and safety rules interact (stowage planning).

Scheduling Optimization Techniques for Crane Deployment

Crane deployment determines throughput at the berth. Effective scheduling optimization matches crane allocation to vessel arrival patterns and cargo mix. First, planners forecast crane demand per bay. Second, they sequence crane moves to cut idle time. Third, they balance workloads across multiple quay cranes so no single crane becomes a bottleneck. One approach applies integer programming to assign time windows and lift sequences. Another uses heuristic or metaheuristic methods, such as tabu search and genetic algorithms, to explore many feasible schedules quickly. For complex terminals, integrated algorithms combine exact and heuristic solvers to achieve practical run times.

Balancing workloads reduces waiting time and smooths yard flow. The scheduling method must also coordinate between the quay and yard to avoid excessive truck queues and yard clash. For example, a coordinated schedule that staggers crane assignments prevents peak pileups on the yard side. Numerical experiments show that smarter crane schedules can cut operational delays by up to 18% and reduce energy consumption by lowering idle moves. Moreover, a hierarchical control structure helps: strategic allocation sets crane counts per berth, and tactical controllers adjust minute-by-minute. In stressful scenarios, stochastic models and robust schedules help maintain service levels despite variability in arrivals. In addition, simulation tools allow planners to simulate different dispatch rules and see their impact on the number of containers moved per hour. For an applied view on balancing restow reduction with crane productivity, read our analysis on balancing restow and crane productivity in deepsea container ports (balancing restow).

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Forecasting Demand and Resource Allocation

Accurate forecast tools allow terminals to allocate resources proactively. Machine learning models predict vessel arrivals, peak volumes, and gate traffic. For example, ETA prediction models use AIS feeds and historical patterns to reduce deviation from schedule. Then planners use those forecasts to adjust staffing, crane counts, and yard slot allocation. A data-driven approach paired with a digital twin can simulate scenarios before implementation. That way, resource planning adapts to predicted peaks and reduces unnecessary waiting time.

Predictive models also support decisions on where to place incoming containers. When forecasts show a surge, the system can reroute containers to less busy stacks to minimize reshuffling later. In addition, combining forecast outputs with a scheduling optimization layer helps create discharge plans that are resilient to stochastic delays. For terminals that aim to minimize rehandles, the integrated plan protects future moves while maximizing moves per hour. Loadmaster.ai’s RL agents use simulated experience to learn policies that adapt to forecast uncertainty and maintain robustness. This system-of-systems view treats quay cranes, yard cranes, truck dispatch, and gate flows as interacting subsystems, and it optimizes their coordination between the quay to the yard. For further reading on ETA prediction and forecast techniques, see our work on machine learning for port operations ETA prediction (ETA prediction).

Case Study: Impact of Discharge Sequence Optimization

In a real-world case study at a major global terminal, a program of discharge sequence reforms produced clear gains. The terminal combined a mixed-integer linear programming model for strategic allocation with heuristic scheduling for operational execution. Then, they layered simulation-based tests and a set of integrated algorithms to refine the policy. The result was a measured 12% increase in throughput and an 18% drop in vessel dwell for peak-season calls (operational performance evaluation). Also, the terminal reported fewer yard clashes and lower energy consumption after they reduced the number of unnecessary moves.

Key lessons included the importance of data quality, the benefit of a benchmark programming model for comparison, and the need to test robustness under stochastic scenarios. The project used a mixed-integer programming backbone and numerical experiments to evaluate trade-offs between crane productivity and yard congestion. In addition, adoption succeeded because planners retained control through explainable decision outputs, and because the new plan addressed loading processes on both the quay side and yard side. For teams considering similar projects, start with a clear definition of objectives and a pilot that focuses on a small set of berths. Then expand the scope as you measure gains and tune the system. Finally, terminals to minimize disruptions should pair forecast updates with real-time adjustments to the discharge process. For a pragmatic guide to scenario-based capacity optimization and AI, see our scenario-based capacity optimization article (scenario-based capacity optimization).

FAQ

What is discharge sequencing and why does it matter?

Discharge sequencing is the order in which containers are unloaded from a vessel. It matters because the sequence affects crane cycles, yard placement, and future moves, and it therefore impacts vessel turnaround and terminal throughput.

How much can optimization reduce vessel turnaround?

Studies show that well-executed discharge sequencing and optimization can reduce turnaround by up to 15–20% and increase throughput nearly 12% in simulation and pilot studies. The exact gain depends on terminal layout and cargo mix.

Which algorithms work best for sequencing?

A mix works best: integer programming and mixed-integer linear programming model formulations give strong baselines, while heuristics, simulated annealing, tabu search, and genetic algorithms provide speed. Combining methods yields practical, robust solutions.

Can forecasts improve resource allocation?

Yes. Forecasts for arrivals and gate peaks let planners pre-allocate cranes and yard slots, which reduces waiting time and reshuffling. Machine learning and ETA tools make those forecasts more accurate over time.

How do cranes influence terminal performance?

Crane deployment directly sets the pace at the berth. Balanced workloads across quay cranes lower idling and avoid creating yard congestion. Smart scheduling reduces waiting time for trucks and yard cranes.

What role does simulation play in implementation?

Simulation lets teams simulate policies, test edge cases, and run numerical experiments without risk to live operations. It supports training agents and validating programming model assumptions before deployment.

Is automation necessary to optimize sequencing?

Automation helps but is not strictly necessary. However, automation and AI enable real-time adjustments and closed-loop control, which significantly improve robustness and consistency compared to rule-based approaches.

How do you measure success for a sequencing project?

Measure success with vessel turnaround time, yard throughput, number of rehandles, crane utilization, and waiting time metrics. Energy consumption and reduced operational delays are also useful KPIs.

What challenges impede adoption?

Common challenges include data quality, change management, integration with TOS, and ensuring explainability for planners. Pilots that preserve planner control and produce clear benchmarks overcome these hurdles more easily.

Can terminals optimize train-related flows too?

Yes. There are solutions focused on optimizing train discharge in port and optimizing train discharge in port terminals that coordinate rail and yard moves. Integrated planning across modes reduces bottlenecks and improves optimal efficiency.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.