Overview of AGV Charging in Terminal Operations

Automated Guided Vehicles play a central role in the modern automated container terminal. They handle horizontal transportation between quay cranes and yard stacks, and they support loading and unloading operations with precision. For an automated container terminal to sustain throughput, battery management must run like clockwork. Inefficient battery management raises energy consumption, forces waiting for charging, and increases completion time for container moves. Therefore, terminals must optimize AGV charging plans and deploy robust algorithmic approaches to keep flows steady.

First, consider the basic scheduling problem for AGVs. Terminals coordinate quay crane cycles, yard crane lifts, and truck gates. Then, they must schedule charging so AGVs remain available without creating queueing at charging stations. The challenge multiplies when terminals use battery-powered automated guided vehicles with limited charging rate and limited charging stations. To solve the problem, researchers model battery levels, charging time, and task queues. They also include charging constraint and charging threshold settings to protect battery life. A well-crafted algorithm reduces idle time, and it reduces repair and replacement costs.

Next, operators apply scheduling models and integrated scheduling to align energy for AGVs with terminal cycles. For example, an algorithm based approach can assign charging tasks to specific slots and sequence trips so that AGVs avoid peak congestion. This reduces overall energy consumption, shortens completion time, and helps meet service-level targets. For more context on related yard and crane planning techniques that interact with AGV flows, see our guide on container terminal automation fundamentals (container terminal automation fundamentals).

Moreover, the agv scheduling problem becomes a joint configuration and scheduling optimization when operators consider swapping strategies or limited number of charging points. In practice, terminals use an algorithmic mix of heuristics and exact models, and they sometimes include genetic algorithm routines for route assignment or for balancing loads. Also, terminals often test scheduling optimization against historical demand to validate charging scheduling before live deployment.

SCSD-ITT Strategy for Balanced State of Charge and Downtime

SCSD-ITT stands for State of Charge and Scheduled Downtime – Intelligent Time Threshold. This algorithmic strategy combines a battery-aware scheduling model with planned downtime windows. The idea is simple and powerful. First, an algorithm monitors State of Charge for each automated guided vehicle in the fleet. Then, the algorithm triggers scheduled downtime when it identifies an efficient slot, and it uses an intelligent time threshold to avoid unnecessary top-ups. As a result, the approach balances AGV utilization and battery health in a coordinated way.

SCSD-ITT treats charging as a scheduling task rather than as an emergency fix. It sequences charging tasks so that AGVs recharge during natural idle periods or low-demand windows. This reduces interruptions to transportation and cutting waiting for charging. In trials, SCSD-ITT helped terminals cut battery life loss by up to 20% reducing battery life loss through optimized charging strategies. The study notes that this effect lowers equipment replacement costs and minimizes operational interruptions caused by battery maintenance “reducing battery life loss through optimized charging strategies not only lowers equipment replacement costs but also minimizes operational interruptions caused by battery maintenance, which is vital for long-term ACT cost control”.

Furthermore, SCSD-ITT can integrate charging constraint parameters such as charging rate limits and maximum allowed depth-of-discharge. Operators can tune the charging threshold for each AGV type and charging station. The model also reduces unnecessary charging time by avoiding frequent shallow charges. As a result, SCSD-ITT improves AGV availability. To explore how yard layout and crane timing affect these gains, consult our piece on dynamic stowage and yard optimization (container terminal yard optimization software solutions).

Finally, the SCSD-ITT algorithm can run alongside fleet-level scheduling and agv dispatching systems. It provides a scheduling plan that coordinates transportation and charging tasks, and it reduces costly clashes between AGV trips and charging slots. The approach solves the agv scheduling problem with battery constraints while protecting battery life.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Flexible Dual-Threshold Charging for Adaptive Scheduling

The Flexible Dual-Threshold Charging (FDTC) algorithm adapts charging thresholds to workload rather than using fixed cutoffs. FDTC sets two SoC limits. The upper threshold limits how long an AGV must charge before returning to service. The lower threshold triggers a return to base for a recharge. This flexible approach lets the scheduling model adapt in real time. As a result, terminals can better align AGV charging with short spikes in horizontal transportation demand.

Compared to fixed-threshold methods, FDTC improves throughput by roughly 15% on average in published tests Battery-Powered AGV Scheduling and Routing Optimization with Flexible Dual-Threshold Charging Strategy. The algorithm reduces idle time and reduces the frequency of emergency charging tasks. Consequently, the agv scheduling strategy becomes more resilient when workloads fluctuate across shifts or when vessel calls bunch up. The FDTC algorithm also reduces energy consumption by preventing unnecessary top-ups and by smoothing charging load on limited charging stations.

In practice, FDTC connects with other algorithms that manage routing and agv path planning. The algorithm uses real-time telemetry to choose whether an AGV should accept a delivery task or head to an available charging station. Also, the model takes into account charging characteristics, limited number of charging plugs, and charging rate limits to avoid conflicts. This results in fewer delays in transportation operation and improved completion time for container moves.

FDTC fits into broader scheduling optimization frameworks. For instance, it can plug into an integrated scheduling tool that synchronizes quay crane cycles, yard moves, and charging schedules. For operators interested in AI modules that aid terminal planning and in automating decision rules, see our resource on AI modules for automated container port planning (AI modules for automated container port planning).

Reinforcement Learning for Dynamic Charging and Routing

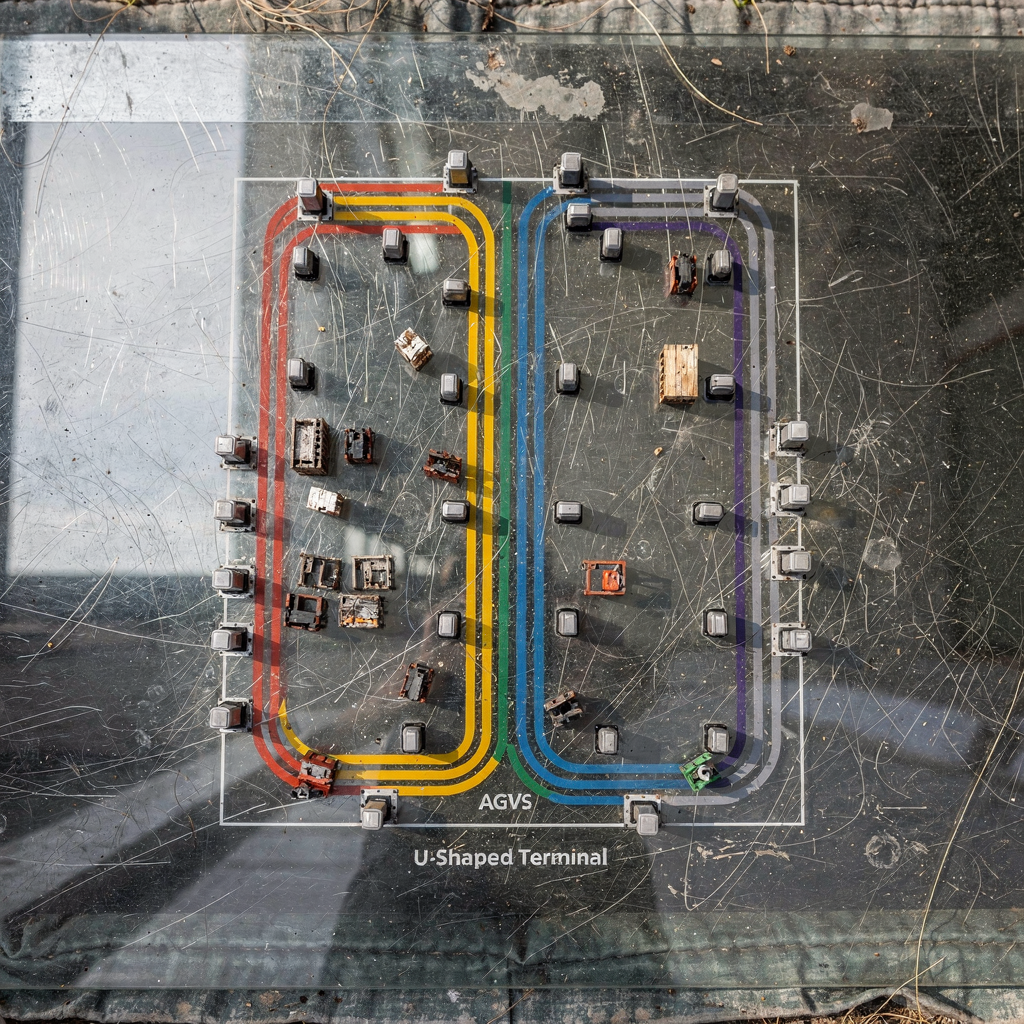

Reinforcement learning algorithms offer a dynamic alternative to rule-based scheduling. For example, a reinforcement learning based AGV scheduling model developed by Yang and colleagues targets U-shaped automated container terminal layouts. In that u-shaped automated container terminal, RL learns when to route AGVs, when to recharge, and when to accept tasks. The algorithm adapts online to congestion, to changing arrival times, and to variable energy demands.

RL makes decisions that reduce idle time and improve scheduling resilience. Reported results show more than a 10% reduction in AGV idle time and improved container handling rates when using RL in trials A Reinforcement Learning-Based AGV Scheduling for Automated Container Terminals. The algorithm balances routing with charging scheduling, and it learns to sequence charging tasks to avoid creating bottlenecks at agv charging stations. Importantly, deep reinforcement learning and genetic algorithm hybrids may further refine policy search while keeping training feasible.

Additionally, RL can incorporate charging constraints and charging characteristics such as non-linear charging curves and differences between battery chemistries. Then, the agent decides whether to accept a transport job or to route the AGV to a charging station. This joint configuration and scheduling optimization helps reduce waiting for charging and it protects agv battery life. For terminals that seek robust real-time conflict resolution between equipment pools, see our guidance on real-time conflict resolution between equipment pools in port operations (real-time conflict resolution between equipment pools in port operations).

Finally, reinforcement learning based solutions support scheduling for automated container terminals by learning from actual operation logs. They handle the scheduling problem with battery constraints, and they help schedule agv transportation to maintain steady throughput even when truck arrivals or berth times shift unexpectedly.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Performance Metrics – Battery Life, Throughput and Cost Impact

Measuring the impact of charging strategies requires clear metrics. Key indicators include battery life extension, AGV availability, throughput, energy consumption, and capital expenditure. For example, optimized charging strategies can reduce battery life loss by up to 20%, which in turn lowers replacement cycles and capital expenditure Optimizing AGV utilization and battery life in automated container terminals. Likewise, FDTC offered about a 15% throughput improvement compared with fixed-threshold methods in experiments Battery-Powered AGV Scheduling and Routing Optimization with Flexible Dual-Threshold Charging Strategy.

When terminals evaluate scheduling models, they track completion time per move and average waiting for charging. Also, they monitor agv energy consumption and agv battery health indicators. Algorithms that reduce unnecessary charging time and that schedule charging during low-demand windows typically show better long-term economic viability. For instance, reducing unnecessary top-ups not only prolongs agv battery but also smooths peak power draw at charging stations, lowering electricity demand charges.

Comparing SCSD-ITT, FDTC, and RL approaches shows trade-offs. SCSD-ITT focuses on battery life and predictable downtime. FDTC adapts SoC thresholds to workload peaks. Reinforcement learning adapts in real time and learns policies under variable conditions. In trials, RL achieved more than a 10% gain in scheduling efficiency and lower idle times A Reinforcement Learning-Based AGV Scheduling for Automated Container Terminals. Combining methods often yields the best results: for example, an RL policy can use FDTC-style thresholds as safety rules, while SCSD-ITT provides scheduled maintenance windows.

To support these algorithmic systems, operations teams need accurate data feeds. By removing manual triage, teams speed responses to charging task alerts and reduce delays that otherwise affect the efficiency of the agv system.

Challenges and Future Directions in AGV Charging Optimisation

Real-world deployment exposes new constraints. Congestion, path conflicts, and fluctuating workload make scheduling for automated container terminals difficult. An algorithm must cope with stochastic arrivals and with path conflicts among automatic guided vehicles. Also, operators must manage limited charging station capacity and unequal charging rates across stations. Addressing these challenges requires richer scheduling models that include stochastic models, digital twins, and multi-resource collaborative scheduling.

Future research should focus on integrated scheduling that pairs quay cranes, yard cranes, and AGV dispatching. Joint configuration and scheduling optimization will improve overall terminal throughput. Also, novel agv resilient scheduling approaches can help maintain service levels when disruptions occur Novel AGV resilient scheduling for automated container terminals. In addition, researchers should study container terminals considering energy consumption explicitly, and they should design algorithms that minimize lifecycle cost of batteries while sustaining throughput.

Further tools, such as digital twins and deep reinforcement learning based planners, will help teams test policies before live rollout. For instance, a digital twin can simulate agv path planning and charging scheduling under different berth schedules. Then, operators can measure completion time, energy for AGVs, and waiting for charging. Genetic algorithm components can speed heuristic search for complex scheduling models, while deep reinforcement learning can learn robust policies from simulated variations.

Finally, cross-team automation matters. When operations teams respond faster to exceptions, terminals maintain throughput. As a result, human teams can focus on strategic adjustments instead of repetitive charging task emails. Continued collaboration between terminal operators, researchers, and AI vendors will help solve the agv scheduling problem with battery and congestion constraints, and it will support the move toward more sustainable transportation operation in ports worldwide.

FAQ

What is the main challenge in AGV charging for automated container terminals?

The main challenge lies in coordinating charging with high-priority transport tasks while avoiding congestion at charging stations. Battery constraints, variable arrival patterns, and limited charging rate make scheduling complex and require sophisticated algorithmic solutions.

How does SCSD-ITT improve battery life and availability?

SCSD-ITT schedules downtime intelligently based on State of Charge and predicted task windows, which reduces shallow cycling and unnecessary top-ups. This approach reduces battery life loss and keeps more AGVs available for operations.

What benefits does Flexible Dual-Threshold Charging offer?

FDTC adapts SoC limits to current workload, which prevents emergency charging and improves throughput. Trials indicate about a 15% throughput gain compared to fixed thresholds.

Can reinforcement learning handle real-time terminal changes?

Yes. Reinforcement learning models learn policies that adapt to congestion and shifting workloads in real time. Research shows RL can reduce AGV idle time by more than 10% in some layouts A Reinforcement Learning-Based AGV Scheduling.

How do charging strategies affect terminal costs?

Optimized charging strategies extend battery life and reduce replacement expenses, which lowers capital expenditure. Also, by reducing interruptions, they improve throughput and reduce labor and energy overheads Optimizing AGV utilization and battery life.

Are digital twins useful for testing AGV charging algorithms?

Absolutely. Digital twins let teams simulate various scenarios, including berth delays and truck surges, and they reveal impacts on completion time and charging scheduling. They enable safe validation of scheduling optimization before deployment.

What role do charging stations play in scheduling design?

Charging stations are critical resources that impose capacity and charging rate constraints. Scheduling models must treat them as scarce assets and sequence charging tasks to avoid bottlenecks and to reduce waiting for charging.

How can terminals combine multiple algorithms effectively?

Terminals can use hybrid approaches: rule-based thresholds for safety, SCSD-ITT for planned maintenance, and reinforcement learning for dynamic routing. This layered algorithmic design balances robustness and adaptability.

Can email automation help AGV charging operations?

Yes. This reduces delays in addressing charging tasks and supports more reliable operation of the agv system.

Where can I find more resources on integrating AGV charging with terminal planning?

For integrated planning and AI decision support, review resources on AI modules for port planning and on container terminal yard optimization. See AI modules for automated container port planning (AI modules for automated container port planning) and container terminal yard optimization software solutions (container terminal yard optimization software solutions).

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.