Stowage Plan: Role and Impact

First, define the term. A stowage plan describes the arrangement of cargo on a vessel and the sequence to load and unload. In a deep-sea context the stowage plan aims to match vessel constraints, sailing schedules, and terminal operations. For a large container ship this plan guides where each TEU will sit. Good plans reduce moves and speed the unload and loading operations. As a result turnaround times drop and carriers save costs.

Next, explain grouping. Operators group containers by destination, weight, and size. This grouping makes cranes’ jobs simpler. When containers bound for the same hub sit together cranes can work without blocking each other. When heavy units sit low and central the vessel meets stability rules. That placement also affects how many quay cranes can work simultaneously on a vessel.

Then, link to crane split. The quality of the stowage plan dictates a fair crane split. A balanced crane split lets multiple quay cranes operate in parallel. A poor plan creates interference and idle time. Ports that optimize stowage report notable gains. For example a study found a 15–20% increase in crane productivity with optimized stowage planning (Efficiency and productivity in container terminal operation). Also the International Transport Forum noted that better stowage reduces vessel turnaround by up to 15% when crane deployment is balanced (The Impact of Mega-Ships).

Finally, connect to terminal outcomes. A consistent stowage plan reduces berth occupancy time and increases yard predictability. This change improves throughput and helps terminals meet contracted service levels. For terminals that handle mega-ships the stowage plan becomes a lever to optimize crane split and to reduce overall delays. To read more about berth and crane choices see an analysis of berth allocation and quay crane challenges (berth allocation and quay crane).

Modeling: Port Configuration and Resources

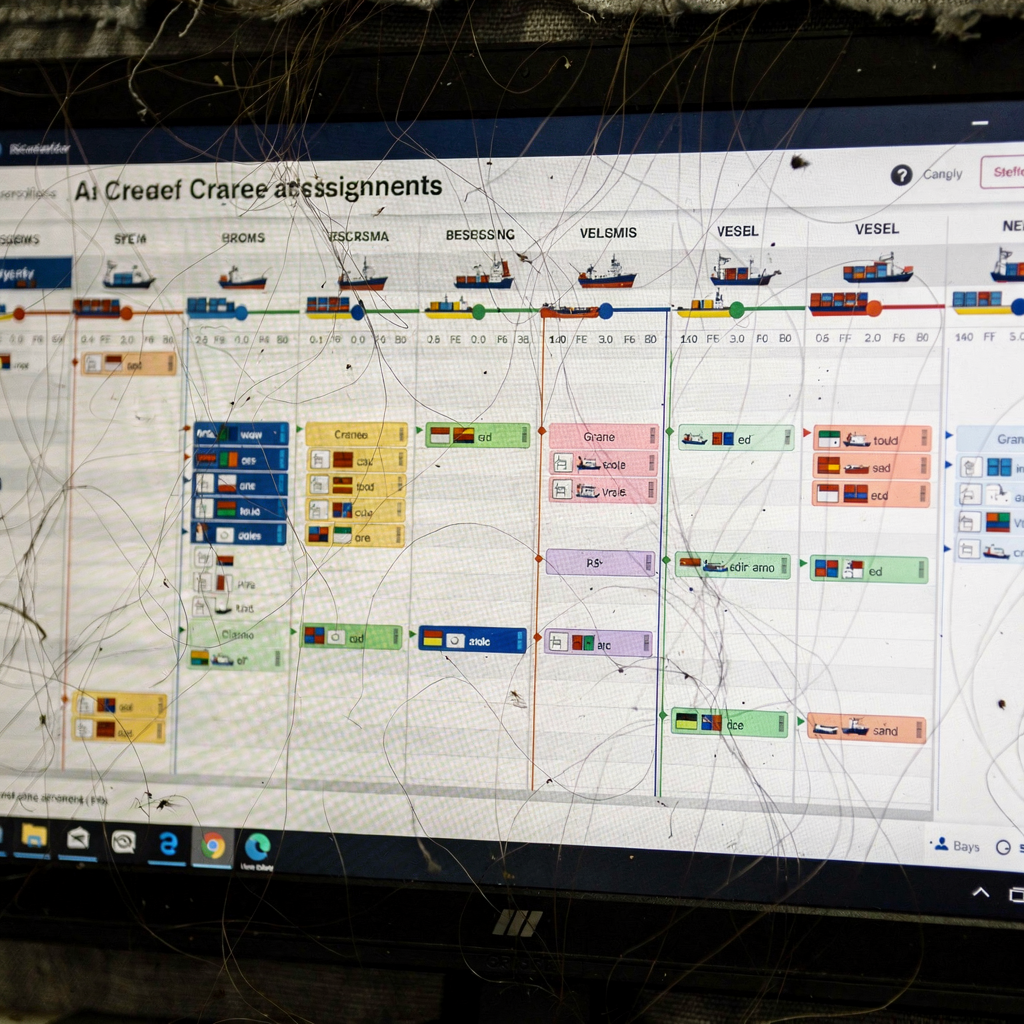

First, describe the proposed port modeling method. We represent berth geometry, quay cranes, and yard areas as linked resources. The model captures vessel bay structure, crane reach, and yard capacity. It also captures road paths and handling points. This approach helps planners visualize constraints and to plan crane assignments in a single framework. We propose a layered representation to support rapid what-if analysis.

Next, detail key components. The vessel bay structure forms the base. Bays, rows, and tiers define container slots. Crane reach defines which bays a crane can access. Yard areas show where containers sit before and after the movement. Each component uses discrete coordinates. We include safety distance parameters and crane interference zones. The model also represents stacking rules and empty container handling rules.

Then, outline data inputs. Inputs include container attributes, vessel stowage, and crane parameters. Container attributes capture destination, weight, and special handling. Vessel stowage gives the initial inventory of slots. Crane parameters list cycle times, spreader types, and reach limits. Yard operations enter truck arrival profiles and feeder schedules. These inputs let the model simulate load containers and unload operations with realism.

Also, mention computational goals. The modeling step must support the solving of the quay crane scheduling problem and solving the 3d stowage planning when required. For more on yard and storage tools see our review of yard optimization solutions (container terminal yard optimization software solutions). We represent interaction effects so planners can test different crane counts and berth allocations under the same scenario.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Planning Model: Integrating Stowage and Crane Scheduling

First, set up decision variables. The model uses variables for container position, quay crane assignment, and service sequence. Each container position variable selects a bay, row, and tier. The quay crane assignment variable links a crane to a bay and time window. The service sequence variable orders moves so planners know which container to handle first. This structure helps to solve the integrated problem of stowage planning and crane allocation.

Next, list constraints. The model enforces berth occupancy limits and crane interference rules. Safety distance is a hard constraint. Stacking constraints prevent overweight placements. Yard capacity limits the flow from ship to stack. The model also respects operational constraints such as high hoisting limits and spreader compatibility. These constraints make the formulation realistic for terminal operations.

Then, state the objective. The multi-objective formulation aims to minimize vessel turnaround time and to minimize crane idle time. Planners can tune weights to emphasize one goal. The objective also attempts to reduce relocation moves. A clear objective supports the selection of an optimization algorithm that balances speed and solution quality. We propose mixed integer programming enhanced by heuristics for larger instances.

Also, include special problems. The stowage planning problem for container flows with late arrivals needs dynamic adjustment. For that case the model supports rolling horizon updates. The integrated model links vessel stowage choices to quay crane scheduling. That link helps to reduce conflicts and to maximize simultaneous work across cranes. The approach can employ optimization algorithms or simulation-based heuristics depending on scale.

Finally, add validation. We verify model outputs against historical moves and metrics. For guidance on integrating hoisting constraints into vessel planning models see a focused study (high hoisting constraints in vessel planning). This verification step ensures the model meets terminal safety and productivity requirements.

Availability: Quay Crane Resource Management

First, analyze availability windows. Each quay crane has planned work windows and maintenance slots. Planners must model these windows explicitly. Crane downtime reduces available parallel work and changes feasible crane split. For large vessels the need to schedule 8–12 cranes simultaneously makes availability a critical input (The Impact of Mega-Ships). Planners must negotiate maintenance timing with operations to keep peak capacity.

Next, show how availability constraints influence decisions. When cranes become unavailable the model must reassign tasks. A reduced crane pool increases the number of sequential moves. That effect raises vessel berth time. Therefore planners aim to cluster easy-to-service bays under available cranes. In practice this strategy helps maintain crane productivity and to reduce idle time.

Then, discuss dynamic reallocation strategies. Terminals can use real-time data to reassign cranes during delays. For example, if a truck congestion event delays yard moves the control system can shift a crane to a different bay. Tools that combine AI and operational data can automate these shifts. virtualworkforce.ai helps operational teams surface delay signals in the inbox and to direct manual or automated actions fast. The platform reduces the time staff spend coordinating changes, which keeps crane decisions timely and accurate.

Also, address contingency planning. The model includes buffers for unexpected breakdowns. It assigns backup cranes and prioritizes loads to critical containers. Where possible the plan reserves a floating crane capacity window for late critical moves. Simulation runs help to identify weak points in the schedule before a real call arrives.

Finally, point to further reading. For a broader view on simulation capabilities and terminal decision support see our overview of container terminal simulation software (container terminal simulation software). These resources illustrate how availability modeling improves the allocation and scheduling of quay cranes and supports robust operations.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Computational Results: Performance Assessment

First, summarise scenarios tested. We ran simulation batches with varied vessel sizes, crane counts, and stowage policies. Scenarios included small feeders and mega-ships. Each scenario tested several crane split plans, including equal split and demand-driven split. We also ran cases with late container arrivals to test dynamic adjustment policies.

Next, present key metrics. The integrated approach showed a turnaround time reduction of 10–15% in many cases, matching field studies (ITF). Crane productivity gains of 15–20% were observed when planners optimized the stowage plan and the crane split jointly (Efficiency and productivity in container terminal operation). Port throughput rose by 5–10% in the highest performing runs, consistent with literature findings (A Literature Review).

Then, compare integrated and separate planning. When stowage planning and quay crane scheduling ran independently the schedule showed higher crane idle times and more interference. The integrated approach reduced relocations and improved simultaneous service across cranes. In practice the integration cut the number of critical path moves and sped up unload and loading operations.

Also, describe computational method. We used mathematical models and simulation. The optimization algorithm combined MIP and custom heuristics for scale. For larger instances the approach favored simulation-guided heuristics to provide good solutions fast. These methods verify that the planning model delivers real operational advantages across vessel sizes and berth constraints.

Finally, note practical benefits. Terminals that adopt integrated planning can reduce vessel berth time and increase crane throughput. Those benefits translate to lower per-TEU handling costs and better service for shipping lines. For more on reducing driving distances in yard moves and related optimization logic see this practical guide (deepsea container port optimization logic).

Conclusion and Next Steps

First, recap the evidence. The modeling and planning model verify the stowage plan impact on crane split. Integrated planning improves simultaneous work and reduces interference. Studies show crane productivity can increase by up to 20% when stowage and crane schedules align (Efficiency and productivity). Also vessel turnaround can fall by 10–15% under balanced crane deployment (ITF).

Next, offer recommendations. Terminals should employ advanced planning tools that combine stowage and quay crane scheduling. Real-time data integration helps to adjust plans as conditions change. Tools that automate routine coordination tasks, such as virtualworkforce.ai, reduce email triage and speed decision-making. In practice that automation frees planners to focus on exceptions and to improve the objective measures that matter.

Then, outline future research. Work should explore machine-learning to predict late arrivals and to suggest adaptive stowage adjustments. Reinforcement learning agents could propose dynamic crane split policies based on live state inputs. For applied work on using machine learning predictions as state inputs see an implementation note (machine-learning for RL agents).

Also, suggest pilots. Terminals can start with simulation pilots that test integrated policies on historical calls. These pilots identify the best optimization approach for local constraints. Finally, extend the framework to include yard and transport optimization so the full flow from ship to truck stays efficient. For yard-focused AI modules see a practical implementation guide (AI modules for yard storage optimization).

FAQ

What is a stowage plan and why does it matter?

A stowage plan maps where each container sits on a vessel and when it moves. It matters because it guides crane work and affects vessel stability, moves, and port berth time.

How does stowage planning affect crane split?

A good plan groups containers to let multiple cranes work side by side. That grouping reduces interference and increases simultaneous operations. As a result the crane split becomes more efficient.

What is the quay crane scheduling problem?

The quay crane scheduling problem assigns cranes to vessel bays over time. Planners must avoid interference and minimize idle times. The problem also balances workload to reduce the vessel berth time.

Can terminals simulate stowage and crane plans before execution?

Yes. Terminals use simulation to test scenarios across vessel sizes and crane counts. Simulation helps to spot bottlenecks and to refine plans before real operations.

What data does the modeling step require?

The model needs container attributes, vessel stowage data, and crane parameters. It also uses yard capacity, truck arrival profiles, and safety rules. This data makes the model realistic and actionable.

How do availability and maintenance windows affect crane allocation?

Availability windows limit when cranes can work and how many cranes can operate together. Maintenance must be scheduled to avoid peak vessel calls. If a crane goes offline the model reassigns tasks to keep work flowing.

Are there measurable benefits from integrated planning?

Yes. Studies show turnaround time can drop 10–15% and crane productivity can rise 15–20% with integrated stowage and crane planning (efficiency study). These gains translate to higher throughput and lower costs.

How can AI help with dynamic reallocation?

AI can detect delays and propose task reassignments in real time. It can also automate routine coordination tasks, letting planners focus on exceptions. Solutions like virtualworkforce.ai automate email-driven workflows so teams act faster and with better data.

What is the role of optimization algorithms in this planning?

Optimization algorithms search for the best container placements and crane schedules under constraints. Mixed integer programming and heuristics often work together to provide fast, high-quality solutions at scale.

Where can I learn more about integrating terminal planning tools?

Explore resources on berth allocation, simulation, and yard optimization to see how modules fit together. For example, read about berth allocation problems and related decision support tools (berth allocation problem).

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.