overview of ai-powered container terminal operating system in maritime logistics

A container terminal operating system combines software, hardware and procedures to manage yard and quay activities. It tracks containers from ship to truck and rail, schedules crane work, and assigns storage. When AI is added, the container terminal operating system gains predictive capabilities, dynamic allocation and faster decision-making. AI-powered modules forecast arrivals, suggest storage locations and adjust plans in real time. This container terminal operating system helps TERMINAL OPERATORS reduce manual planning and increase throughput.

The role of this system in maritime logistics is central. It coordinates vessel handling, truck gates and rail operations so that cargo moves smoothly. A robust system controls crane movements, manages container stacking and drives yard planning. It also integrates with TMS and ERP, so data flows to operator screens and automated guided vehicles. Terminals using AI get alerts, optimization suggestions and improved workflow for everyday tasks.

Common challenges in global container port yards include unpredictable vessel schedules, gate peaks, and limited yard space. Congestion grows when container dwell rises and rehandling happens. Operators face bottleneck incidents and suboptimal utilization. Automated stacking cranes and ASCS can help, but they need smart orchestration. A container terminal operating system that links automation to planning can automate routine decisions and free operators for exceptions. For example, virtualworkforce.ai reduces email triage and lets operator teams spend more time on tactical choices. Using AI, the system can automate notifications and keep operational data current, so the operator sees real-time status and can determine the best next action.

To succeed, deployments must integrate with existing TOS and be easy to operate. The container terminal operating system should support decision-making, connect data sources seamlessly and scale with traffic. That approach helps ports and terminals adapt to global trade shifts and maximise productivity. In short, a modern container terminal operating system with AI balances equipment use, reduces congestion and improves vessel turnaround.

predictive analytics for port optimization and kpis

Predictive analytics models forecast container arrivals, yard occupancy and equipment use to help optimize operations. These AI modules use historical records and real-time feeds. They predict gate peaks and vessel schedules, and they estimate container dwell and processing time. Predictive analytics is essential for accurate allocation of cranes and automated guided vehicles. A recent study shows AI-powered tracking at Jebel Ali Port improved space utilization and eased congestion; operators reported measurable efficiency gains in throughput and yard flows Transforming UAE’s Supply Chain Management through Artificial …. This example highlights how predictive models translate into lower delays.

Key KPIs include throughput, dwell time and space utilization. Throughput measures handled TEU per period. Dwell time shows how long containers stay in the container yard. Space utilization indicates how well yard space is used and affects container stacking and rehandling. Predictive analytics links these KPIs to upcoming vessel calls and truck traffic, so the TOS can schedule slots and crane cycles more efficiently. Ports that apply predictive analytics often see faster vessel turnaround and reduced idle equipment.

Machine learning models can forecast equipment starvation and crane workload, and they can recommend resource pooling. For deeper study on similar modeling approaches, see predictive modeling for port operations and yard capacity predictive modeling for port operations. In practice, models use input like ship schedules, gate logs, container movements and weather. They output short-term forecasts that terminals use to automate dispatch and allocation. That automation to streamline dispatch reduces delays and improves utilization of cranes and AGVs.

Quantitative impacts vary by site. South Korean research reports up to a 20% improvement in yard storage efficiency when AI-enhanced logistics systems are deployed AI-Enhanced Smart Maritime Logistics. Capgemini research suggests unlocking siloed data and deploying AI platforms can raise supply chain efficiency by up to 15% New-generation supply chain – Capgemini. These figures support investment in predictive analytics to optimize KPIs and improve terminal operations.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

ai-driven digital twin for enhanced port management

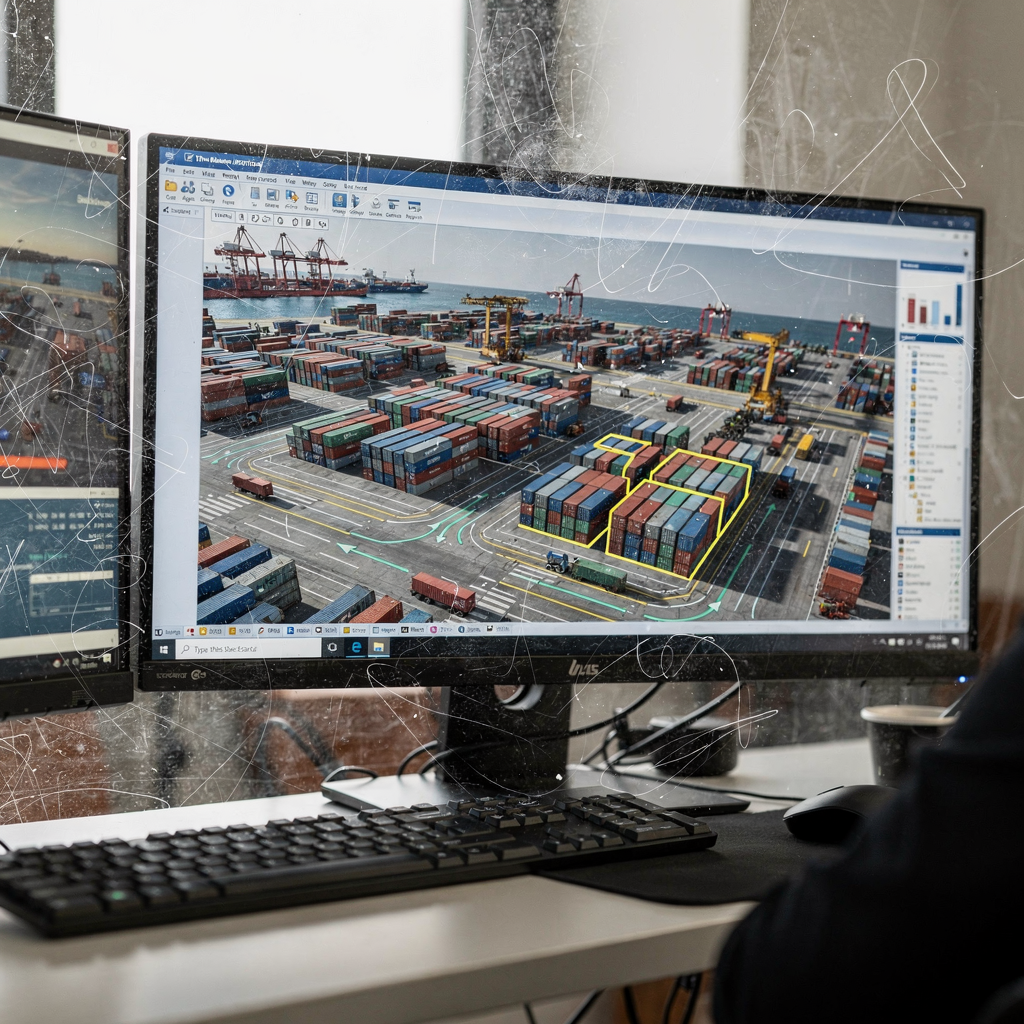

Digital twin technology creates a virtual replica of yard and quay processes for simulation and what-if analysis. A digital twin runs on live feeds and historical records, and it utilizes MACHINE LEARNING to mirror container terminal behavior. When AI is layered on top, simulations become prescriptive rather than only descriptive. The digital twin can test recovery plans, predict congestion propagation and help decision support systems choose resilient courses of action. Researchers report that combining simulation optimization with digital twinning improves port resilience and recovery planning A decision support system for maintaining a resilient port.

Digital twin simulations let operators using a container terminal operating system run scenarios before making changes. For example, the twin can emulate rerouting yard traffic after a crane outage and predict the impact on vessel turnaround. This reduces reliance on trial-and-error in the yard. Digital twin outputs inform automated stacking cranes, AGVs and gate dispatch logic. They also inform container stacking patterns to reduce rehandling and improve utilization.

Metrics for resilience include recovery time objectives, lost throughput during disruption and excess handling events. A well-tuned digital twin helps terminals reduce the recovery time and the number of rehandlings. It also supports safety by simulating traffic flow and identifying transfer points where accidents occur more often. For practical guidance on dynamic replanning during disruptions, see dynamic internal transport replanning during disruptions in deepsea container ports dynamic internal transport replanning. That resource shows how simulation and decision support systems enhance response speed.

Digital twin adoption requires connectivity and clean operational data. Systems must ingest real-time telemetry from cranes, truck gates and yard sensors. They must also link to existing TOS so simulation insights can be applied in current operations. When done correctly, AI-driven twins enable terminals to determine the best allocation under pressure and to maximise throughput without compromising safety or sustainability.

dynamic slot allocation with terminal operating and yard management

Dynamic slot allocation uses algorithms to assign storage slots by considering size, destination and handling priority. Machine learning models analyze container flows and recommend allocations that minimise reshuffles. These recommendations travel from the container terminal operating system to yard crews and automated guided vehicles. A key goal is to reduce rehandling and improve crane productivity while balancing space utilization.

Within the TOS, algorithms rank containers by priority, and they map slots that shorten travel and crane movements. The system can also reserve contiguous slots for export blocks, which speeds loading. By using AI models that learn from past operations, allocation becomes adaptive. That reduces bottleneck risks and shortens processing time for each container. South Korean ports saw up to a 20% efficiency improvement in yard storage when AI-enhanced logistics controlled allocation and layout AI-Enhanced Smart Maritime Logistics.

Yard management benefits directly. Fewer reshuffles mean fewer crane cycles and less fuel consumption for yard tractors. The optimized yard increases utilization and keeps container dwell lower. Terminals also notice higher productivity in crane work and faster vehicle turnaround. For strategies that reduce driving distances and improve crane workload distribution, consult container terminal optimization logic to reduce driving distances reduce driving distances and crane workload distribution resources crane workload strategies.

Algorithms must handle uncertainty in ship schedules and truck arrivals. They must also integrate human preferences and safety rules. The best solutions combine rule-based logic with learning models so the allocation adapts while respecting constraints. This hybrid approach helps terminal operators and their crews trust automated recommendations and improves adoption. In time, these systems maximise throughput and support higher service levels that attract shipping lines.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

ai modules to integrate container terminal and terminal operating systems

AI modules must integrate smoothly with existing TOS and with broader management systems. Integration lets predictive analytics, digital twin outputs and dynamic allocation feed into daily operations. The module architecture often exposes APIs for event-driven data exchange and for upstream systems like ERP and TMS. When systems integrate well, real-time data flows and decision-making improve. Event data exchange among stakeholders also improves gate and vessel coordination Whitepaper Machine Learning in Maritime Logistics – shipzero.

Benefits include reduced manual handoffs, faster responses to exceptions and fewer information gaps. For example, AI systems can parse emails about schedule changes and update the TOS automatically; virtualworkforce.ai provides that kind of automation for email workflows so operators get faster, data-grounded updates. This reduces processing time and keeps operational data consistent across teams. Integration also supports automated guided vehicles and ASCS by supplying slot and task directives.

Technical challenges include legacy TOS APIs, inconsistent data formats and limited connectivity. Recommended solutions start with an event-driven API architecture and a middleware layer that normalises messages. For details on event-driven approaches, see event-driven API architectures for container terminals event-driven API architectures. Security and governance must be part of the integration plan so that data to improve planning stays accurate and auditable.

Seamless integration lets the container terminal operating system automate routine work and escalate only exceptions. That automation reduces email and manual triage, boosts operator productivity and helps teams focus on strategic tasks. As AI adoption grows, modules that integrate well will drive better port operations and higher overall terminal performance.

case studies of optimization in terminal management with ai-powered yard management

Real-world deployments show measurable gains. Dubai’s Jebel Ali Port uses AI for container tracking and yard optimization. That deployment improved space utilization and reduced congestion while raising throughput; details are available in an industry study Transforming UAE’s Supply Chain Management through Artificial …. The Port of Newcastle in Australia is extending AI analysis modules to improve yard operations, which signals growing AI adoption across global ports Driving the digital transformation of transportation.

South Korean ports that adopted AI-enhanced logistics reported up to 20% improvement in yard storage efficiency AI-Enhanced Smart Maritime Logistics. These improvements came from better allocation, fewer rehandlings and smarter yard planning. Capgemini estimates that AI platforms that break down silos can increase supply chain efficiency by up to 15% Capgemini research. Those figures reinforce the business case for investment in AI.

Best practices include starting with a clear set of KPIs, phasing rollouts, and linking AI outputs to operator interfaces. Terminals should pilot predictive analytics for scheduling, then layer on allocation and digital twin simulation. They should also build trust by showing measurable gains in processing time and throughput. For practical steps to improve crane productivity and reduce truck turnaround, examine optimizing quay crane productivity and reducing truck turnaround time resources optimizing quay crane productivity and reducing truck turnaround time.

Looking ahead, AI will further connect yard decisions with wider supply chain flows. Terminals that integrate AI modules with their TOS will better manage congestion, improve vessel turnaround and help global trade move more predictably. With careful integration and governance, AI-powered yard management can deliver durable gains in utilization and productivity.

FAQ

What is a container terminal operating system and why add AI?

A container terminal operating system is software that manages quay, yard and gate activities. Adding AI gives the system predictive analytics and dynamic allocation so operators can optimize crane schedules and reduce rehandling.

How does predictive analytics improve terminal KPIs?

Predictive analytics forecasts arrivals, yard occupancy and equipment demand. That forecasting helps operators reduce dwell time and increase throughput by planning resources ahead of peaks.

What is a digital twin and how does it help during disruptions?

A digital twin is a live virtual replica of yard and quay operations. It runs simulations to test recovery actions and shows decision-makers the fastest ways to restore throughput during a disruption.

Can AI reduce container reshuffles and rehandling?

Yes. Dynamic slot allocation and machine learning-driven allocation reduce the need to move containers several times. Fewer reshuffles lower crane movements and save time and energy.

How do AI modules integrate with existing TOS?

Integration usually happens through APIs or middleware that normalise event data. An event-driven architecture helps modules exchange messages and update the TOS in real time.

Are there measurable benefits from AI at real ports?

Yes. Studies report up to 20% improvement in yard storage efficiency in South Korea and clear throughput gains at Jebel Ali Jebel Ali study. These results depend on data quality and rollout strategy.

What technical challenges do terminals face when deploying AI?

Common challenges include legacy software, inconsistent data formats and limited connectivity. Using an event-driven API layer and data governance helps address these issues.

How do AI modules affect operator workflows?

AI modules automate routine planning and flag exceptions, so operators handle fewer repetitive tasks. Tools like virtualworkforce.ai can also reduce time spent on emails and manual coordination.

Can AI improve sustainability at terminals?

Yes. Better allocation and fewer rehandlings reduce fuel use and emissions. Optimized yard planning also improves energy efficiency in equipment operation.

Where can I read more about specific AI solutions for terminals?

Explore resources on predictive modeling, crane productivity and event-driven APIs for practical guidance. For example, check predictive modeling for yard capacity predictive modeling for port operations, optimizing quay crane productivity crane productivity, and event-driven API architectures API architectures.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.