port: an overview of modern terminal operations and logistical complexities

Ports are complex hubs for global trade. A container terminal handles unloading and load planning, vessel schedule, and yard stacking. First, vessels arrive and request a berth slot. Next, quay cranes navigate containers from decks to trucks or rail. Then, yard tractors move containers to storage bays. Meanwhile, intermodal transfers link ships with inland barge or rail routes. stakeholders range from shipping lines to customs officers, crane operators, and port authorities. Business processes in these environments demand clear workflows, robust communication, and precise timing. For example, cargo volume peaks can trigger yard congestion, long waiting times, and higher demurrage costs. Therefore, planners must coordinate vessel berthing, crane assignment, and gate dispatch in a cohesive plan. real-time dashboards drive situational awareness, providing clear views of slot availability and equipment utilization. A maritime hub might process over 100,000 TEUs monthly, and any delay can cause cascading backlogs. In addition, rising global trade complexity demands more adaptive scheduling solutions. In complex systems, manual rules struggle with dynamic yard states and sudden equipment failures. However, by analyzing data on arrival times, planners can refine container stacking patterns for faster quay turnaround. Also, cross-stakeholder coordination ensures that shipping lines, truckers, and rail operators align on timing. Finally, as ship sizes expand, ports must revisit terminal optimization strategies to boost capacity and reduce idle time. The next chapter outlines how simulation modeling captures these dynamics in a safe, risk-free environment using digital representation of key variables in a simulation model.

simulation modeling: employing discrete-event models to replicate port activities

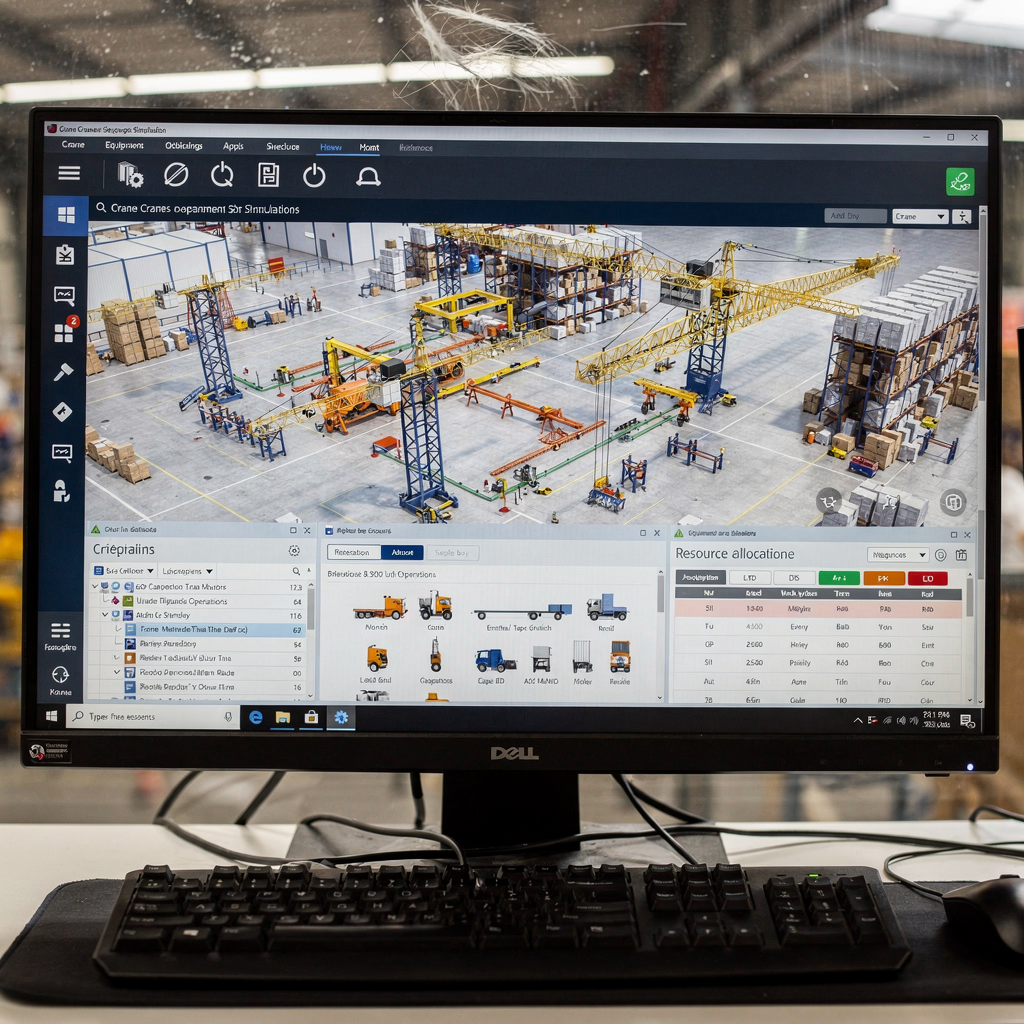

Discrete-event simulation software offers a way to analyse equipment usage and vessel flows. In port operations, planners test schedules without interrupting live activity. They deploy simulation tools that mirror quay crane performance and yard stacking. For example, a DES approach can capture variable truck arrivals, stochastic crane breakdowns, and peak demand periods. That method creates a stress test environment for container handling processes. In addition, discrete event modules allow fine tuning. Furthermore, by using agent-based modules, users simulate collaborations between automated guided vehicles and human operators. Also, risk mitigation plans can be verified by evaluating worst-case scenarios. In one study, terminal regulators reported a 15% gain in throughput using AI-enhanced models [15% gain]. Discrete event simulation software integrates data on vessel ETAs, turn cycles, and crane operations. Users can input variables for yard crane speeds, truck loading rates, and quay space. A common tool, flexsim, provides drag and drop interfaces for quick scenario building. Also, using 3d modules enhances analysis. With anylogic libraries, engineers link scheduling software to simulation engines. When planners review visual feedback on a control console, they spot bottlenecks days before actual deployment. Using simulation, teams can predict truck delays for trucks and reduce idle time. That leads to topline savings and lower demurrage risk. A robust port and terminal simulation software package will include lifecycle analytics, reporting tools, and support for visualization. Meanwhile, a port simulator can model cross berth coordination and yard resource allocation. In addition, some providers offer consultancy to train in-house staff. Finally, this chapter shows how simulation is a powerful tool that drives smarter berth allocation and supports continuous performance improvement.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

digital twin simulation: creating a virtual replica of port and terminal operations

Teams can also test unload performance under heavy winds. Digital twin simulation builds a virtual copy of a container port to mirror physical layouts and resource flows. Proper logistics coordination reduces errors. First, engineers define system requirements, including yard dimensions, quay lengths, and gate locations. In addition, users set performance targets and safety margins. Then, the digital model ingests live sensor data, IoT feeds, and TOS inputs to update the virtual system on the fly. Analysts gain visual feedback through interactive interfaces that show vessel berths, container yard slots, and truck circuits. In this framework, a tool for port and terminal integrates mapping, equipment telemetry, and weather data to account for environmental factors like wind speeds or tide variations. Furthermore, terminal simulation software layers traffic rules on top of the physics engine to control mover speeds and crane acceleration. That approach lets teams evaluate unloading sequences under different weather conditions. Also, developers can apply optimization algorithms to refine container stacking patterns and gate dispatch routines. For instance, simulation modeling helped improve system performance and reduce energy use by 12% in a pilot study [12% improvement]. Users can inspect kpis in a scenario comparison view to decide on equipment upgrades. Meanwhile, since this method supports port and terminal operations planning, executives get confidence in investment decisions. A verifiable process ensures that any option can be audited. Through agent logic and event triggers, the twin tests disruption response plans for storms, equipment breakdowns, or labor shortages. With this digital twin framework, port planners can conduct what-if analysis on berth expansion or yard layout changes. They can simulate new quay sections, test truck lane configurations, and run pressure scenarios for crane spacing. That capability is crucial when budgets limit physical pilots. Also, the twin supports training of new operators without risking real equipment. Because the model runs separate from live processes, developers achieve an isolated environment for innovation. Overall, digital twin simulation accelerates decision cycles and sharpens resource use, moving port hubs toward higher operational efficiency.

optimize allocation and throughput: using simulation software to enhance crane productivity

Simulation software can optimize resource allocation to improve quay crane productivity. Initially, planners assign moves based on container sizes, yard block proximity, and vessel loading sequences. Then, they adjust parameters through batch runs to compare results. For example, a South Korean study showed a 20% reduction in container dwell time and a 12% rise in crane output [20% reduction]. That finding demonstrates how dynamic rules trim idle time and demurrage costs. Simulation also sharpens crane operations by sequencing tasks to avoid idle swings. Also, by simulating gate flows, teams identify peak arrival clusters and reroute trucks to less busy lanes. In addition, they test allocation of straddle carriers to limit equipment overlap in storage blocks. As a result, crane stays busy without waiting for ground handling. Meanwhile, a port simulator can compare multiple scenarios in parallel, offering rapid what-if insights. Planners then review a central control panel to measure resource uptime and travel distances for each crane. Through iterative trials, they refine rules to balance quay and yard workloads. Furthermore, system architects evaluate the impact of adding cranes or reallocating storage zones before committing to capital expenditure. Finally, these exercises enable operational teams to adopt best practices in scheduling and maintain a steady flow of containers in the yard. Also, teams can model varied crane speeds to estimate resource uptime under high volumes. They can simulate fog or rain conditions to assess buffer zone sizes. Such granular analysis boosts resilience and consistency in everyday terminal operations.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

case studies: analysing real-world applications of terminal simulator implementations

To illustrate the impact of advanced analytics, we examine three real deployments. In Australia, a coastal facility implemented an AI-driven dispatch module to adjust truck schedules and match crane availability. The result was a 15% faster vessel turnaround and a 10% drop in standby fees [15% faster]. In the UAE, operators used port simulation software to test a new berth layout. They achieved a 25% improvement in overall logistics efficiency and reduced vessel idle berths by 8% [25% improvement]. Next, a European terminal enlisted support to integrate a virtual twin of its port terminal. Using high-fidelity models, the team identified idle crane periods and rebalanced yard workloads, boosting crane utilization by 10% [10% boost]. Another project in North America combined TOS integration with a virtual prototype. The site cut turnaround times by 20% and improved stack stability. Planners analysed gang sizes, straddle carrier dispatch rates, and stack assignments to minimize dwell. They also revised forklift paths to ensure safe stacking margins. By tweaking crane cycle times and stack heights, they cut rehandles in half. This tool delivered ease of use, enabling rapid scenario changes. These gains translated into smoother vessel schedules and lower handling expenses. For more detailed reports, see our simulation case studies page. Also, planners can compare leading solutions on our best container terminal simulation software for planning guide. In addition, port simulation reduces operational risks by forecasting trade-offs. Ultimately, these examples show how any port or terminal can harness simulation to inform capital planning and upgrade strategies.

decision support and automation: integrating digital twin and automation for smarter terminal optimization

Integrating digital twin insights with automation drives proactive decision support in complex port environments. Modern solutions layer AI agents on top of real-time twins to balance quay and yard demands. For example, our StowAI, StackAI, and JobAI modules collaborate to sequence vessel moves, assign storage slots, and orchestrate equipment dispatch. Similarly, port and terminal managers rely on unified dashboards that visualize live KPIs and identify potential bottlenecks. This closed-loop system uses reinforcement learning to explore policy spaces beyond historical patterns. In practice, decision support interfaces aggregate live KPIs, highlight planning conflicts, and propose corrective actions. Simulated what-if trials for gate peaks or crane failures run in seconds, helping planners preempt holdups. automation scripts then trigger equipment tasks without manual handoffs, ensuring constant crane liveness and minimal queue buildups. Also, hybrid rigs can reroute lifts to spare machines during breakdowns. Meanwhile, a central control panel shows resource allocation, system alerts, and performance trends. By combining digital twin data and AI-driven rules, operators achieve more stable port volume and better resilience to disruptions. To learn more about our approach, visit our terminal decision support simulation page. With this framework, terminals shift from reactive firefighting to proactive planning, reducing rehandles, cutting travel distances, and enforcing operational guardrails in real deployments.

FAQ

What is port logistics simulation software?

Port logistics simulation software creates a virtual representation of container handling, vessel berthing, yard stacking, and gate operations. Users can test scenarios like different vessel mixes, crane assignments, and truck flows without disrupting live activities.

How does discrete-event simulation help terminal operations?

Discrete-event simulation captures stochastic arrivals, equipment usage, and resource queues as a sequence of events. It supports stress testing, what-if analysis, and risk mitigation strategies for terminal planners.

What benefits do digital twins provide for port and terminal operations?

Digital twins integrate live sensor data, equipment telemetry, and environmental factors to mirror real-world conditions. They enable real-time decision support, visual feedback, and continuous performance improvement.

Can simulation software reduce vessel turnaround times?

Yes. Studies report up to 15% faster turnaround using AI-enhanced models and optimized berth assignment. Simulation allows planners to refine scheduling, crane sequences, and yard flows.

What role does AI play in port decision support?

AI agents analyze dynamic variables in a simulation model to recommend load sequences, yard placements, and dispatch actions. They learn policies that optimize multiple KPIs and adapt to new conditions.

Is automation safe for live terminal operations?

Automation scripts run in a closed-loop environment with hard constraints and live guardrails. This risk-free environment ensures that tasks only execute when conditions match simulation criteria.

Which internal links explain container yard modelling?

For detailed methods, see our guide on how to model container yard operations. It covers layout design, demand forecasting, and scenario testing.

How do case studies illustrate simulation value?

Case studies show real deployments where ports achieved 20% dwell time reductions, 10% crane utilization gains, and 25% logistics efficiency improvements. They highlight proactive planning and capital investment decisions.

What is the ease of use for terminal simulation software?

Most platforms offer drag-and-drop interfaces, prebuilt libraries, and interactive dashboards. These features enable rapid scenario building and minimize system requirements for hardware setups.

How soon can a terminal see ROI from simulation?

Terminals can observe measurable benefits within weeks of running initial scenarios. Savings on demurrage fees, reduced idle time, and smoother vessel schedules often deliver ROI within months.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.