terminal and TOS: Foundations of container terminal management

A terminal is where ships meet land logistics. In that space, a terminal operating system (TOS) coordinates moves, resources, and timing. The TOS schedules quay cranes, tracks cargo, manages the container yard, and plans vessel work. It links gate activity to yard planning and links yard planning to vessel sequencing. For terminals that aim to improve productivity, a modern TOS is essential.

Market figures show the investment scale. Implementation costs range from about $500,000 to over $2 million depending on scope and customisation ($500k–$2m+ implementation estimate). The top 25 TOS providers cover many terminal sizes and complexities (Top 25 TOS providers). Studies report up to 30% productivity gains after deploying advanced systems that include AI and rich data feeds (up to 30% productivity gain). These numbers help justify investment when terminals must handle changing vessel mixes and peak cycles.

Key features matter. Real time data collection underpins planning and execution. AI-driven predictive maintenance reduces downtime and out-of-service hours. Modular design and user-friendly interfaces let terminals scale capabilities block by block. TOS now integrate with external telemetry, equipment control systems, and third-party APIs to manage automation and manual assets alike. That means a single scheduling view that balances quay crane work, stack utilisation, and truck turn times. TOS parameters are tuned to local rules and to the actual configuration of the yard.

Operators must also evaluate vendor fit. For example, some terminals compare Navis and other vendors in depth to pick a system that matches their operational philosophy; see a detailed comparison for commercial context Navis vs alternatives. For an overview of leading solutions and alternatives, a useful resource summarises market offerings and features best terminal operating systems 2025. Our company, Loadmaster.ai, builds RL agents that work with your TOS. We create a digital twin to train policies and then integrate with TOS software via APIs so the planner uses smarter allocation without replacing the TOS.

simulation model to analyse port and terminal operations

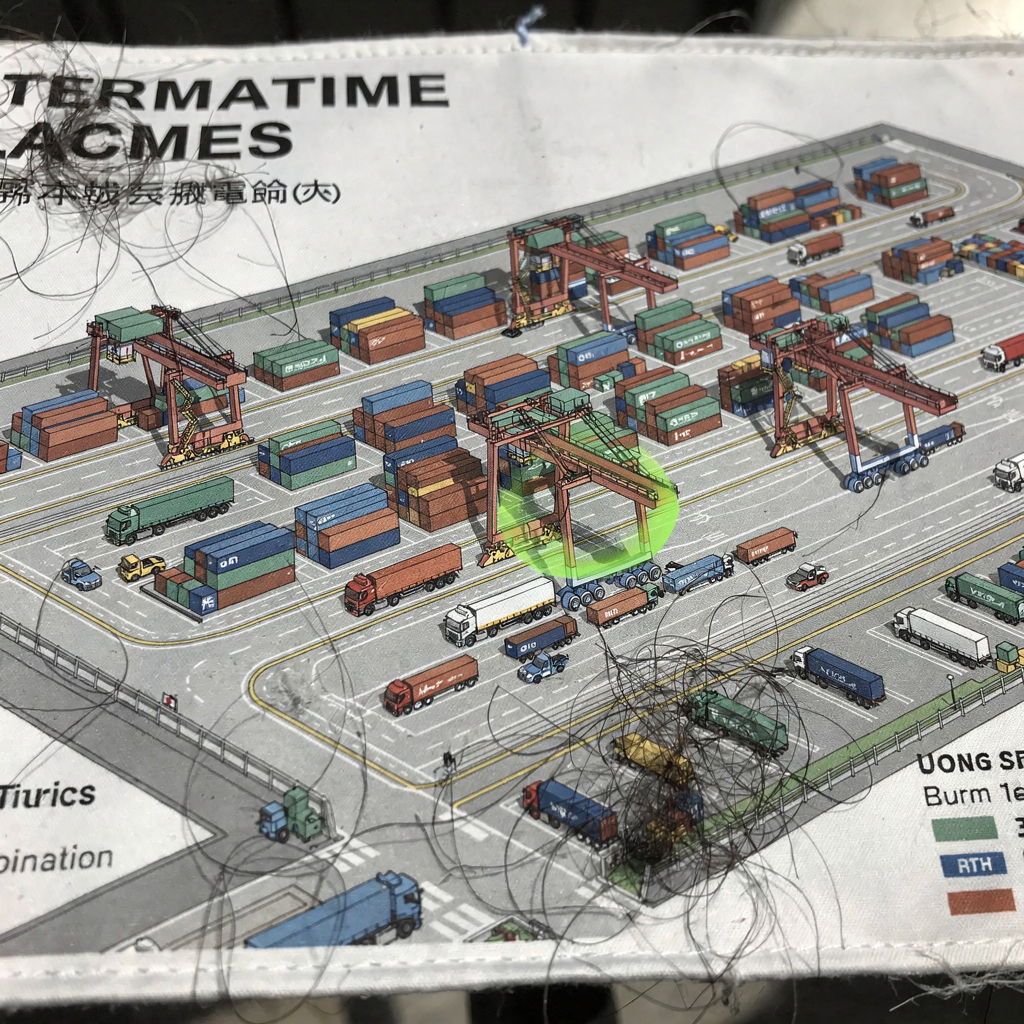

Simulation models are the tools planners use to test ideas before they touch the real terminal. There are three common approaches. Discrete-event models represent events such as truck arrivals, crane moves, and gate checks. Agent-based models treat yard actors as agents that interact and adapt. Digital twin models mirror live systems and allow dynamic testing. Each model type suits different questions. Discrete-event models are fast for queuing and resource studies. Agent-based models expose emergent equipment behaviour. Digital twins support real-time tuning and visualisation.

Quantitative benefits can be compelling. When linked to live TOS data, combined studies show as much as a 20% throughput increase and up to 15% cost reduction in some trials (20% throughput, 15% cost improvements). That occurs because the model identifies bottleneck sources and suggests smarter allocation of cranes and trucks. Simulation and emulation tools help run operational scenarios for berth assignment, quay crane sequencing, and gate staffing without risking normal operations (simulation across terminal lifecycle). Using simulation fosters data-driven decisions and builds a business case for automation investments.

Planners use the simulation model to optimise layout choices and test new terminal layouts before committing to heavy civil work. They can test different quay crane counts, yard block shapes, and equipment mixes such as RTGs, AGVs, or straddle carriers. Simulation allows visualisation of truck turn patterns and helps estimate moves per hour under varied staffing and gate policies. For teams that need tools and reviews focused on software selection, an internal guide outlines simulation software and planning workflows what simulation software do container terminals use. In short, models convert uncertainty into quantified trade-offs and provide a safe space to evaluate alternatives.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

model and emulation for virtual terminal training

Emulation differs from simulation. Emulation replicates real terminal interfaces and behaves like a real system under test. Simulation creates hypothetical flows and studies performance. Emulation allows operators to connect actual TOS software, or equipment control systems, and validate changes without impacting live operations. In practice, emulation provides a virtual environment where staff can learn and where new settings can be validated before rollout.

Virtual terminal setups serve multiple purposes. First, they train dispatchers and planners on new workflows in a realistic setting. Second, they let IT teams test new tos parameters and integrations with navis or other solutions. Third, emulation helps validate equipment behaviour and control logic for AGVs, RTGs, or straddle carrier fleets. For open-source options and tools suited to Linux, see an overview of available packages open source terminal simulation software. For commercial solutions, emulation tools are part of enterprise simulation toolkits that support vendor testing and operator training enterprise simulation tools.

Emulation to PSA’s Pasir Panjang terminal has been used in real projects to test changes without disrupting live activity. In that example, operators tested gate rule changes and quay crane sequences and thus reduced risk at go-live. Emulation allows a TOS vendor and terminal teams to run operational scenarios against a replica of their system. That approach lowers the chance of regressions when new tos software or new tos updates arrive. For teams building AI agents, emulation provides the real terminal signals needed to validate a policy before it goes back to the TOS and into operations.

container terminal simulation to optimise congestion and throughput

container terminal simulation helps planners prepare for peaks and sudden shifts in demand. The approach models arrivals, berth occupancy, yard congestion, and gate queues. Planners use the model to test buffer strategies, temporary blocks, and dynamic berth windows. In practice, simulation shows where bottleneck risks will appear and suggests tactical remedies to reduce dwell time.

Case studies show measurable wins. For example, tailored studies reduced average dwell time and smoothed container handling during peak weeks. In many terminals, moves per hour improved after layout tweaks and reallocation of quay crane time. The gains led to lower truck turn times and better utilisation of cranes. Terminal simulation has been successfully applied to plan temporary changes during equipment outages and to redesign gate operating hours without disrupting yard flow (test and optimise workflows).

Integration with a TOS is key for continuous optimisation. When live terminal data streams feed the model, the digital twin can recommend crane reassignments and yard reshuffles in real time. That is how teams can dynamically optimise crane allocation, reduce rehandles, and lower energy use. For terminals looking specifically at congestion, simulation can test changes in stacking rules or the introduction of automated guided vehicles (AGVs). A practical guide explains how to simulate container terminal operations and use results to change standard operating procedures how to simulate container terminal operations. The result is a repeatable process that improves efficiency and reduces costly surprises.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

turning to simulation and emulation to optimise TOS decision-making

Turning to simulation and emulation creates a feedback loop between planning and execution. First, models run what-if experiments. Next, teams feed results back to the TOS for better allocation of cranes and trucks. This closed-loop concept helps the TOS make smarter choices on allocation, berth windows, and yard placements. AI-driven optimisation then refines those choices over time.

AI plays a central role. Reinforcement Learning agents can learn policies in a sandbox and then operate against live signals. Our approach at Loadmaster.ai uses a digital twin and RL agents to train StowAI, StackAI, and JobAI. These agents optimise multi-objective KPIs and then link with the TOS via APIs. That reduces rehandles, balances stack workloads, and increases crane utilisation without changing core tos software.

Practically, the loop looks like this. Build a model that mirrors your actual configuration. Train or test policies in that virtual environment. Validate decisions using emulation and a replica TOS. Then move proven changes back to production. This lets terminals improve productivity and avoid larger disruptions. It also protects tribal knowledge and stabilises performance across shifts. For more on marrying simulation with TOS configuration, see a resource on simulation and optimisation tools for TOS simulation and optimisation tools for TOS.

analyse port and terminal operation for future trends

To plan wisely, terminals must analyse metrics and emerging technologies. Key metrics include throughput, utilisation, congestion levels, and cost per move. Measuring moves per hour and truck turn times gives a factual base for investment. Regular evaluation helps terminals prioritise where to automate and where to add staff. It also helps to identify the true bottleneck in each operational scenario.

Emerging tech will shape the next decade. Digital twin technology supports continuous improvement and allows rapid testing of new terminal layouts. Advanced AI will support berth and crane assignment and dynamic staffing recommendations. Cloud-based TOS solutions will enable collaborative planning across terminals and shipping lines, and they will let smaller operators access powerful tools. For terminals that want to explore capacity planning and reduce bottlenecks, there are dedicated tools and simulation software reviews to help choose the right stack terminal capacity planning software and port and terminal simulation software reviews.

Investment strategies should balance new tos features with simulation and emulation capacity. A phased approach works best. First, stabilise core TOS and instrumentation. Second, invest in accurate models and a virtual terminal. Third, deploy AI agents trained in-sim to improve operational decisions. That path reduces risk, speeds time to value, and helps terminals adapt to changing cargo mixes and berth schedules. As terminals modernise, the synergy among TOS, simulation, and emulation will grow and provide valuable insights for resilient, efficient port and terminal operations.

FAQ

What is the difference between a TOS and simulation?

A TOS runs and controls daily terminal operations in real time. Simulation creates models to test scenarios and quantify trade-offs before implementation.

Can simulation improve throughput?

Yes. Studies show that linking models to live data can increase throughput by up to 20% in some cases (throughput improvements). Simulation reveals bottlenecks and suggests targeted changes.

How does emulation help during TOS upgrades?

Emulation lets teams validate changes against a replica TOS without affecting live operations. This reduces rollout risk and lets operators test settings without disrupting the real terminal.

Do I need historical data to use AI agents?

Not always. Some agents, like our RL models at Loadmaster.ai, learn in simulation and do not require large historical datasets. That helps terminals that lack clean history to still improve productivity.

What is a digital twin in terminal management?

A digital twin is a live model of the terminal that mirrors flows and equipment. It supports continuous testing and helps optimise berth, crane, and yard allocation decisions.

How much does a TOS implementation cost?

Costs vary widely. Typical implementations range from $500,000 to over $2 million depending on scale and customisation (cost estimate). Additional modules and integrations add to the project scope.

Can simulation reduce yard congestion?

Yes. A targeted simulation study can evaluate changes in stacking rules and gate policies to reduce yard congestion and improve truck turn times. Results then guide practical layout and staffing adjustments.

What role does automation play with a TOS?

Automation, such as AGVs or remote cranes, extends the capabilities of a TOS by reducing manual steps. The TOS and equipment control systems must integrate closely for safe and efficient operation.

Is there open-source simulation software for terminals?

There are open-source options that support basic modelling and training. For consolidated enterprise needs, commercial simulation software provides advanced features and vendor support (open-source guide).

How can a terminal start with simulation and emulation?

Begin by defining key KPIs and building a simple model of your yard and quay operations. Then expand the model, add emulation for TOS validation, and iterate with controlled pilots to validate benefits before full rollout.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.