Discrete event simulation: foundations and scope

Discrete event simulation defines a class of models where state changes occur at distinct moments. Firstly, it maps events such as loading, travel, unloading, and maintenance to discrete timestamps. Secondly, it models queues, resources, and interactions in realistic ways. Thirdly, it helps stakeholders evaluate operational choices rapidly. For transport operations, the method fits because vehicles, docks, and handlers operate in event-driven cycles. Consequently, managers can evaluate the performance of PLANS before they touch the tarmac or yard. A computer simulation provides safe test space for those PLANS. For example, the Federal Highway Administration recommends “Users should use simulation modeling to get verifiable results, not just theoretical predictions” FHWA. This advice highlights why teams must validate models with measured data. Also, a study on truck costing notes that “Developing costs in the trucking industry requires use of many data sources,” which supports careful input collection truck costing model. In practice, discrete event simulation handles complex systems with many interacting parts. Next, it allows sensitivity analysis and what-if comparisons without disrupting operations. Therefore, planners can test staffing, routing, or downtime policies safely. In addition, discrete techniques link to supply chain planning by exposing how delays propagate. Furthermore, they let teams perform scenario ranking based on KPIs. If you want specific steps to model a terminal or yard, see our guide on how to simulate container terminal operations for practical templates and methods how to simulate container terminal operations. Finally, the approach serves both high-level strategy and low-level control design. Overall, this foundation sets expectations for accuracy, data needs, and the role of computer simulation in system design and decision making.

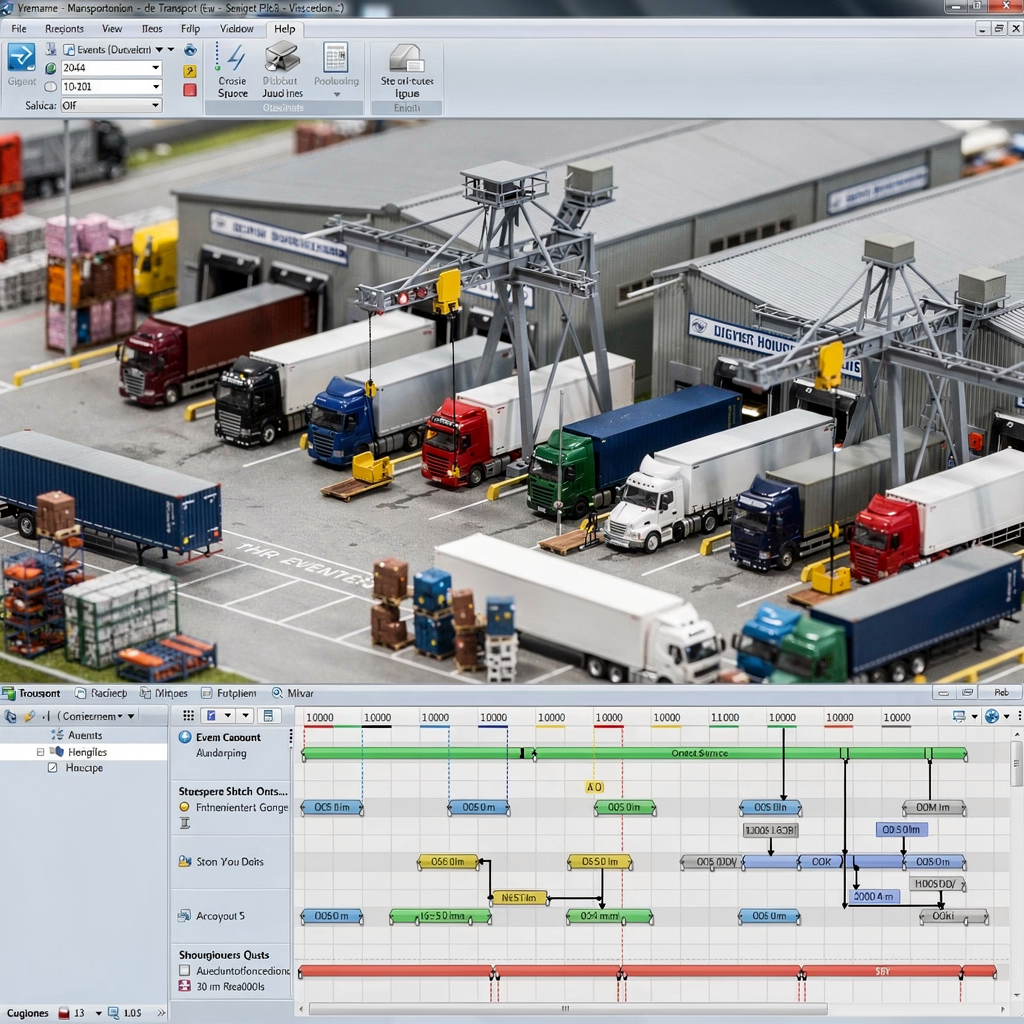

Simulation model: building a virtual transport framework

Building an effective simulation model starts with clear objectives. Firstly, identify throughput goals and the KPIs you will evaluate. Next, gather vehicle profiles, sensor feeds, and road network maps as input. Additionally, include material flow rates and estimated service times. Then, break the model into modules for dispatch, routing, queuing, and downtime. A queue module must represent waits at docks and repair bays. Moreover, use a simulation engine that supports event scheduling and state tracking. For larger projects, integrate simulation software that interfaces with telemetry. For instance, some teams use Simulia and Dassault Systèmes 3DEXPERIENCE for end-to-end virtual testing; those tools support design exploration and reduce development time warehouse simulation findings. At the same time, lighter-weight simulation modeling software fits pilots and academic studies. Importantly, the architecture must allow data exchange with a digital twin and with analytics pipelines. Therefore, teams can accelerate iteration when real telemetry arrives. Also, a clear plan for material handling and vehicle dynamics simplifies later validation. Use simulation solutions that support scenario libraries. Then, you can create possible scenarios for peaks, failures, and planned maintenance. In addition, document design decisions so analysts and developers can reproduce runs. To automate routine evaluation, connect the model to scripts that execute batch experiments. Finally, engage analysis experts to perform design analysis and to confirm that the model was used correctly. For port and terminal-focused readers, our comparison of simulation and optimisation tools for TOS provides further context on selecting platforms simulation and optimisation tools for TOS.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Heavy equipment: characterising assets for accurate simulation

Correctly describing heavy equipment is essential to build fidelity. Firstly, list types of heavy mobile equipment and assign capacity, speed, and turnaround times. Secondly, tag each unit with maintenance intervals and fuel or battery states. Thirdly, include parameters for the powertrain and for vehicle dynamics so the simulation reflects acceleration, braking, and load effects on travel time. Additionally, record operator safety limits and brake performance for realistic cycle times. The model should also note payload capacity, tare mass, and coupling properties for trailers. In practice, heavy equipment simulation depends on measured logs. For that reason, gather sensor logs, time studies, and maintenance records. Also, consult equipment manufacturers for duty cycles and recommended service intervals where possible. Next, map material handling equipment—such as forklifts and gantries—to their task sets. Then, capture variability in speed and refuelling patterns so the virtual fleet behaves like the real one. Furthermore, describe the industrial equipment interfaces that affect loading rates. Also, mention electrical subsystems when fleets include electric machines or when electrification is under consideration. Finally, compare physical testing data with simulated outputs. This cross-check shows gaps and helps teams iterate. If you need deeper reading on terminal process planning that links to equipment characterisation, see our terminal process planning tools primer terminal process planning tools. Automation trends mean teams should plan for both automation and human-in-loop controls when they simulate heavy machinery in mixed environments.

Haulage: optimising routes and schedules through simulation

Haulage modelling focuses on routing, loops, and timing. Firstly, define delivery routes and the road network constraints. Secondly, compare single haulage loops with multiple concurrent loops, and consider conveyor interfaces in fixed installations. For conveyor-fed yards, model the conveyor capacity and its interactions with vehicle arrivals. Additionally, include railway interfaces where intermodal transfer happens. Then, design scenario experiments to test on-time deliveries under peak demand and under disruptions. Next, apply route-planning algorithms that factor road grade, speed limits, and vehicle powertrain limits. For complex road networks, include turn restrictions, weight limits, and grade effects. Also, implement dynamic re-routing policies in the model to reflect live traffic or closures. Use the simulation model to identify the primary bottleneck in each haulage pattern. Once identified, test staggered dispatch or buffer points to reduce idle time. Simulation can show fuel consumption differences between schedule strategies and quantify idle reduction; simulation studies suggest utilization gains of up to 15–20% through targeted optimisation warehouse-to-net-zero study. In addition, applied truck costing research shows idle time can account for 25–30% of operational time and thus deserves focus truck costing model. Use simulation to compute on-the-road durations and to measure queue lengths at docks. Subsequently, compare baseline and optimised schedules to evaluate fuel and time savings. Finally, document algorithms and delivery rules so operations teams can implement the best performing policies in production.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Equipment utilization: metrics, analysis and optimisation strategies

Measuring equipment utilization starts with clear KPIs. Firstly, capture utilisation rate, cycle time, and downtime percentage. Secondly, record capacity utilization for fleets to see spare capacity or overuse. Thirdly, track mean time between failures and repair time to inform preventative maintenance. Use consistent kpis to compare baselines with improved schedules. For example, when simulation modeling helped planners test staggered dispatch, they often saw a 15–20% improvement in throughput in comparable studies simulation gains. Also, simulation-driven schedules reduce idle time and excess fuel burn by consolidating trips and by smoothing arrival patterns. To optimise asset use, recommend preventative maintenance windows, dynamic re-routing, and shift-level dispatch rules. Additionally, embed condition-based triggers from sensor logs so you can accelerate maintenance before failures occur. In practice, equipment must be profiled across operating scenarios including peaks, normal flow, and failures. Use a combination of simulation modeling software and analytics to simulate the effects of different maintenance cadences. Then, evaluate how each policy affects downtime percentage and on-time deliveries. Furthermore, compare baseline and optimised runs to show quantified gains in utilisation and in operating cost. Lastly, link results into planning and TOS systems to close the loop. For terminal operators seeking solutions enablement, our article on reducing terminal bottlenecks by simulation provides practical steps to integrate results into operations reduce terminal bottlenecks. Overall, this metric-led approach aligns maintenance, dispatch, and routing to raise capacity utilization and improve resilience.

Case study: validating haulage scenarios in the mining industry

This case study summarises a discrete simulation of heavy equipment in a mine-haul operation. Firstly, the team built a digital twin of a surface mine to represent loading points, haul roads, and dump sites. Next, the model was populated with heavy mobile equipment profiles, payload distributions, and average service times. Then, the project performed simulation runs for single-loop and multi-loop haulage, and for conveyor-integrated layouts. The model was used to test possible scenarios such as a shift in ore grades, temporary road closures, or a surge in demand. The performed simulation showed that throughput increased when trucks were re-sequenced to align with shovel cycles. As a result, bottleneck occurrence at the primary crusher dropped significantly. The simulation-driven approach also enabled a feasibility study of electrification and of hybrid powertrain options for select trucks. In addition, the study included multibody vehicle dynamics checks and a multiphysics simulation of battery thermal behaviour to guide design decisions. The team used these outputs to evaluate the performance of proposed interventions and to validate maintenance windows. For context, optimisation produced an 18% increase in equipment deployment efficiency in an urban air mobility study that used similar evaluation methods UAM study. Finally, the creation of digital assets shortened development time and reduced reliance on physical prototype trials. The next steps are to pilot AI-driven predictive maintenance, to expand twin technology across the fleet, and to integrate reinforcement learning agents that can accelerate decision-making on dispatch. If you are exploring enterprise-grade tools, our enterprise simulation tools for port logistics page can provide relevant examples and options enterprise simulation tools for port logistics.

FAQ

What is discrete event simulation and why use it for haulage?

Discrete event simulation models systems where changes occur at distinct events, such as loading or unloading. It is ideal for haulage because trucks, conveyors, and cranes operate in cycles that map to events, which makes modelling efficient and expressive.

What data do I need to build a transport simulation model?

You need vehicle profiles, service times, road network data, material flow rates, and maintenance histories. Also include sensor logs and time studies to improve accuracy and to validate model outputs.

How can simulation reduce idle time in heavy equipment fleets?

Simulated scenarios let planners test dispatch rules and buffer locations without disrupting production. By identifying bottleneck points, teams can introduce staggered dispatch or dynamic re-routing to reduce waits.

Can a digital twin replace physical testing entirely?

No. A digital twin complements physical testing and shortens iteration by resolving many design questions virtually. However, physical testing still proves final designs and verifies aspects that remain hard to model.

What role does predictive maintenance play in equipment utilization?

Predictive maintenance uses condition data to schedule service before failures occur, thereby reducing downtime percentage. Simulation lets teams test maintenance cadences and estimate their impact on utilisation.

Which tools support heavy equipment simulation and digital twins?

Tools range from lightweight simulation modeling software to full platforms like Simulia and Dassault Systèmes 3DEXPERIENCE. Choice depends on project scope, required fidelity, and integration needs.

How do I validate a simulation model?

Validation requires comparing model outputs with measured timing, throughput, and failure rates from operations. Iteratively refine inputs and repeat experiments until the model reproduces observed behaviour.

What metrics should I track to measure equipment utilization?

Track utilisation rate, cycle time, downtime percentage, and capacity utilization. Also monitor mean time between failures and on-time deliveries to tie maintenance and scheduling to operational outcomes.

Is it possible to automate decisions using simulation results?

Yes. A simulation environment can feed rules and policies into control systems, and AI agents can learn from simulated experience to automate dispatch or stacking decisions. This approach can accelerate response to disruptions.

How do simulation studies inform electrification or hybridisation of fleets?

Simulation can model powertrain performance, energy consumption, and thermal effects under typical duty cycles. That lets teams evaluate electrification feasibility and design analysis before costly field trials.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.