octopi tos: Scope, Definitions and User Access

Octopi’s Terms of Service, often referenced as octopi tos, set the boundaries between the provider and the user. First, the agreement defines who the user is and what the service covers. For clarity, the TOS usually specifies the meaning of “user”, “service”, and “data.” Next, the document clarifies subscription conditions, trial periods, and grounds for termination. For example, a trial may end automatically, and a paid subscription often renews unless the user cancels. Also, the TOS will state acceptable payment methods and refund policies. Therefore, reading the trial conditions matters before you sign up.

octopi is a modern cloud-based platform built for small to medium operations; the phrase appears in marketing and documentation to set expectations. However, the legal scope still limits liability and defines permitted uses. For instance, users must not attempt to reverse-engineer the terminal operating system or extract data improperly. In practice, companies that run mixed cargo terminals or container and mixed cargo terminals will see specific clauses about multi-cargo workflows. For those who want deeper technical context, Loadmaster.ai maintains resources that explain how simulation links with a TOS, such as the tools for simulation of yard behavior (TOS simulation model tools).

Conditions for registration and access also address account security. Users must protect credentials and notify the provider of unauthorized activity. If the provider detects a security issue, it can suspend access immediately to protect the broader ecosystem. Moreover, the TOS sets rules for permitted API calls and EDI exchanges. You should also review related pages on TOS integration and yard simulation to understand integration patterns (simulate yard operations and TOS integration). Finally, definitions often link to operational terms like yard management, stuffing, and CFS procedures so the agreement fits real work on the ground.

tos: Legal Obligations, Liability and Privacy

Under the TOS, users face clear legal obligations. They must use the service lawfully and avoid prohibited activity. For example, the TOS typically forbids scraping or bulk harvesting of data without permission. As Octoparse advises, “always review the website’s Terms of Services (ToS) and robot.txt” when you gather external data to prevent legal trouble (“always review the website’s Terms of Services (ToS) and robot.txt”). Therefore, companies must align their data practices with the TOS before integrating the platform.

Privacy is another central pillar. The document usually explains data collection, storage, and processing, and it commits to compliance with GDPR and similar regimes where applicable. For example, the TOS may describe how personally identifiable information is used for authentication and audit logs. Also, the agreement can explain data retention, deletion requests, and the handling of backup copies. In many cases, Octopi or similar providers list specifics about anonymization and the rights users have to request data access or correction.

Liability and indemnification clauses limit company exposure. Providers often state the service is provided “as is,” and they cap damages. Yet users remain responsible for their operational choices, including integration with third-party systems. The SourceForge review notes Octopi’s strong operational feature set and adoption among terminals, which supports reliability claims (SourceForge on Octopi’s capabilities). If disputes arise, the TOS usually prescribes mediation, arbitration, or jurisdiction clauses. For enterprise customers, negotiation may change some terms, particularly on data residency or audit access. Finally, firms should confirm those negotiated elements before deployment to ensure legal and operational fit.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

terminal operating system: Features and Automation Capabilities

A terminal operating system provides the operational backbone for modern ports and yards. Octopi offers modules that mirror traditional suites while adding lightweight, cloud-friendly interfaces. Core modules typically include yard management, vessel stowage planning, and equipment allocation. These modules manage the movement and storage of boxes and mixed loads; they schedule stuffing and CFS handoffs too. The platform often supports gate processing and appointment booking to reduce dwell at entry points.

Automation features deserve a focused look. Octopi can automate gate checks, appointment confirmations, and remote operations that formerly required many manual checks. For terminals running a mix of container and non-container flows, the automation helps standardize tasks and minimize paperwork. For example, the system can assign a task to a crane operator and then update the dashboard and downstream systems automatically. For integrators, EDI or APIs provide the necessary connections to shipping lines and customs, matching the best practices outlined in modern integrations. For guidance on how a TOS integrates with Navis or N4 systems, see the Navis N4 overview on our site (Navis N4 terminal operating system).

Furthermore, the platform supplies a dashboard that helps teams measure kpis and visibility. SourceForge noted that users can “easily measure key performance indicators” on Octopi’s dashboard, which helps terminals focus on throughput and equipment utilization (“easily measure key performance indicators”). The software also supports decision logs, audit trails, and role-based access to enhance governance. For smaller sites, lightweight, cost-effective deployment options make the suite accessible. For larger terminals, integration with existing telematics and equipment controls makes execution smoother and more robust.

terminal operations: workflow management to track kpis

Workflow standardization improves consistency and reduces errors. In terminal operations, well-defined workflows ensure each move follows a repeatable path. For example, a crane cycle, an assignment to a driver, and the subsequent yard placement each follow set tasks. This reduces rehandles and improves execution. For teams aiming to deliver better outcomes, the focus on repeatable processes builds resilience and minimizes downtime.

Real-time and real time tracking complement these workflows. Systems record container moves, equipment status, and yard layout changes as they happen. This track capability gives terminal operators better visibility over asset locations and movement. Consequently, supervisors see bottlenecks early and can reroute resources. The visibility into truck arrivals and gate status helps reduce truck turnaround time and enhance throughput. When you need to explore scenario planning or “what if” simulation for workflow changes, Loadmaster.ai provides resources on scenario simulation for TOS planning (what-if scenarios for terminal TOS).

KPIs focus attention on measurable outcomes. Typical metrics include throughput, equipment utilisation, and truck turnaround time. Operators use these indicators to balance quay productivity against yard congestion. Also, tracking the number of rehandles and average crane moves per hour helps teams improve long-term productivity. For mixed-cargo terminals, combining RO-RO and break bulk handling with container flows requires careful planning and an intuitive interface that supports diverse cargo types. Good systems minimize manual handoffs and eliminate paperwork where possible, which reduces delay and enhances operational efficiency.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

port shipping: Data Integration, Compliance and Reporting

Integration drives modern port systems. A TOS must exchange data with port community systems, shipping lines, and customs authorities. To achieve this, the platform supports EDI, APIs, and secure file transfers. For example, EDI messages carry booking, manifest, and gate information. For developers, APIs supply real-time hooks so external systems can subscribe to status changes. If you need integration patterns, our pages on TOS modelling and integration describe common approaches (TOS modelling and simulation tools).

Compliance is non-negotiable. The TOS and the platform enforce rules for customs declarations and environmental reporting. For ports with strict audit requirements, the system must provide a complete audit trail and asset histories. Also, reporting modules create exports for regulators and internal governance. Some terminals rely on standard interfaces to N4 or other systems to maintain a common operational record. In fact, interoperable integration reduces double entry and speeds clearance for shipping manifests.

Security of data exchange matters as much as format. The platform must secure transfers, encrypt files, and log access. For many operators, a secure, documented integration replaces fragile manual processes that once relied on paper. Consequently, the move from paperwork to digital workflows can reduce errors and speed customs clearances. Finally, environmental rules and safety standards sit alongside customs compliance. Platforms that deliver clear reporting and secure integration help terminals meet regulatory needs and support global terminal operations across terminals around the world.

ai indicator: Future Enhancements and Predictive Insights

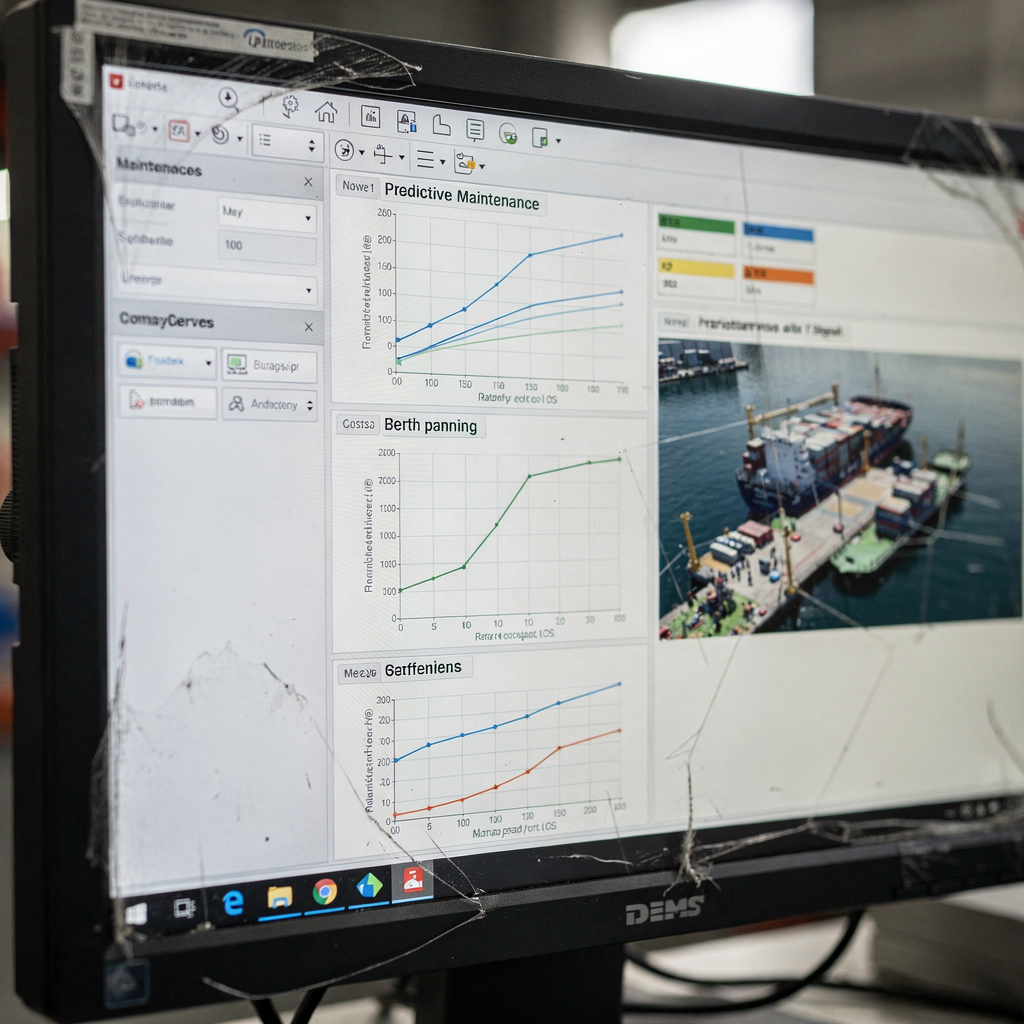

AI now powers predictive modules in terminal systems. Platforms combine predictive maintenance, berth planning, and yard forecasting to cut disruptions. Predictive models forecast equipment failures and suggest maintenance windows, which reduces downtime. Also, AI indicator modules detect anomalies, warn of drift in key performance, and recommend corrective actions. For example, a predictive alert can flag a likely crane fault before it causes a shift-level outage.

Loadmaster.ai builds reinforcement learning agents that augment human planners. Our StowAI, StackAI, and JobAI agents work together to optimize allocation and execution. They train in a sandbox digital twin and then deploy with operational guardrails. This method avoids heavy dependence on historical datasets and delivers rapid gains in productivity. The agents optimize multi-objective KPIs and adapt to new vessel mixes and yard states without lengthy retraining. For teams using established TOS products, our approach remains TOS-agnostic and integrates via API or EDI to deliver smarter execution (TOS planning simulation software).

Indicator modules combine trend analysis with measurable thresholds. They send performance alerts and support human decisions. Also, predictive scheduling reroutes moves and reallocates assets to protect quay productivity while minimizing yard congestion. As a result, terminals can move from firefighting to proactive operations. Moreover, this strategy supports both small container sites and large to mega-sized operations, and it fits lean portfolios and cost-effective deployments. The roadmap for AI includes broader ecosystem links, richer simulation capability, and tighter EDI integration so the tools keep improving over time.

FAQ

What does the Octopi TOS typically cover?

The TOS usually covers user obligations, data usage, service limitations, and liability clauses. It also explains subscription terms, trial periods, and termination rules that govern access to the platform.

How does Octopi handle privacy and compliance?

Octopi’s TOS typically details how data is collected, stored, and shared and cites compliance with GDPR and similar regimes. Users can request access or deletion in line with the provider’s privacy policy and the contractual terms.

Can Octopi integrate with existing systems like Navis N4?

Yes, many TOS platforms integrate with Navis N4 and other systems through APIs and EDI. For a practical overview of Navis integration patterns, see our guide on the Navis N4 terminal operating system (Navis N4 terminal operating system).

Does Octopi support predictive maintenance?

Modern TOS platforms include predictive modules that forecast equipment issues and recommend maintenance windows. These features help reduce downtime and improve execution by prioritizing assets before failures occur.

Are EDI and API both supported for data exchange?

Yes, the platform supports EDI for legacy partners and APIs for real-time integration. Secure file transfers and encrypted APIs help terminals meet customs and port authority requirements.

How do dashboards help terminal operators?

Dashboards provide visibility into kpis like throughput and equipment utilisation so teams can make timely decisions. They also offer audit trails and role-based access for governance and compliance.

What is the role of AI in terminal execution?

AI can optimize stowage, yard placement, and job sequencing to minimize rehandles and balance workloads. Reinforcement learning agents simulate millions of decisions to find better policies than those derived from historical averages.

Can small terminals use Octopi-style features?

Yes, cloud-based and lightweight deployments make key modules available to smaller sites. Built for small container operations, these options reduce upfront costs while delivering measurable gains.

How does integration reduce paperwork?

Digital integration replaces manual forms and paper-based handoffs with automated EDI messages and API callbacks. This change shortens processing time and reduces errors in shipping and customs paperwork.

Where can I learn more about TOS simulation and planning?

Loadmaster.ai publishes resources on simulation and planning, including TOS simulation model tools and what-if scenario pages. See our TOS simulation and planning resources for deeper technical guidance (TOS simulation model tools and what-if scenarios for terminal TOS).

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.