Simulation Model for Container Terminal Operations

What-if simulation helps planners replicate and test container terminal operations before changes reach the yard. In practice, a simulation model maps quay activities, yard moves, gate flows, and truck dispatch. Also, it represents the rules and constraints you use in daily planning. For example, variables in a simulation model include quay crane schedules, yard stacking rules and truck movements. In addition, those variables help identify potential issues such as a bottleneck at the gate or uneven workload on a straddle carrier. The approach supports port and terminal operations and helps terminal operators make data-driven choices.

First, define the scope. Next, pick the level of fidelity. Then, collect historical throughput and equipment telemetry to calibrate the model. Calibration uses actual throughput, berth sequences, and shift patterns so the simulation reflects the real-world system. Also, validation compares model outputs to historical KPIs and idle time and demurrage records to confirm accuracy. The process reduces risk before capital changes or operational changes occur.

Simulation provides powerful visualization and allows planners to stress test a new terminal layout or altered quay crane mix. For example, a discrete event approach models arrivals, queues, and handling systems as discrete events. In addition, discrete event simulation lets you test berth changes and evaluate quay crane productivity. The model supports what-if runs that show how changes affect cargo handling and operator workload. Because the model is transparent, terminal based rules remain clear, and planners can see how a proposed shift affects resources efficiently.

For ports with limited historical data, using simulation and emulation lets teams generate plausible experience. Loadmaster.ai applies this idea by spinning up a digital twin and training agents without requiring cleansed history. The company’s work shows how simulation modeling helped to surface rehandles and reduce long driving distances. Also, when planners simulate multiple scenarios, they can optimize exchange between crane work and yard flow before committing to equipment purchases or software upgrades.

Port Simulation Software: Features and Solutions

Choosing port simulation software begins with use case and scale. Also, select tools based on digital readiness and budget. Leading tools include AnyLogic, Arena Simulation, Talumis Ports Simulation, PTV Vissim, and Siemens Plant Simulation. Each tool has strengths. For example, Arena is often used for discrete event port terminal modelling and can show how equipment choices affect throughput (Arena uses discrete event methods). In contrast, AnyLogic supports multimethod modelling and agent-based components for complex systems.

Essential features include multimethod modelling, scalability, and real-time integration. Also, a user-friendly GUI and robust visualization make results actionable. For terminals that want TOS integration, ensure your simulation tool connects to the terminal operating system (TOS) and handles EDI or API data flows. This lets the model ingest berth plans, vessel stowage, and truck ETA feeds and supports planning tools for daily operations. For more on simulation software options, see a catalog of container terminal simulation software and port-terminal-simulation-tools for comparisons and feature lists.

Selection guidance depends on terminal size, use case, and system requirements. A new terminal with a high proportion of automation will prefer a tool that supports real-time feeds and digital twin capabilities. Conversely, smaller terminals can start with a discrete event package that models yard queues and crane cycles. Also, budget matters. Some vendors offer modular licenses that scale from pilot blocks to full yard modelling. For terminals weighing vendor claims, ask for a port simulator demo, and request runs with your own yard layout and arrival patterns. This step helps identify whether the tool supports complex systems, multiple scenarios, and stress test capability.

Finally, expect the tool to be a platform for ongoing optimization and decision support. A good port simulation software supports what-if analyses, reduces operating costs, and enables planning tools that help port authorities and operator teams prepare for peaks, equipment failure, or gate surges. See Loadmaster.ai’s descriptions of container-terminal-simulation-software and terminal-digital-twin-software for examples of integration paths.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Digital Twin and Decision Support for Port Planning

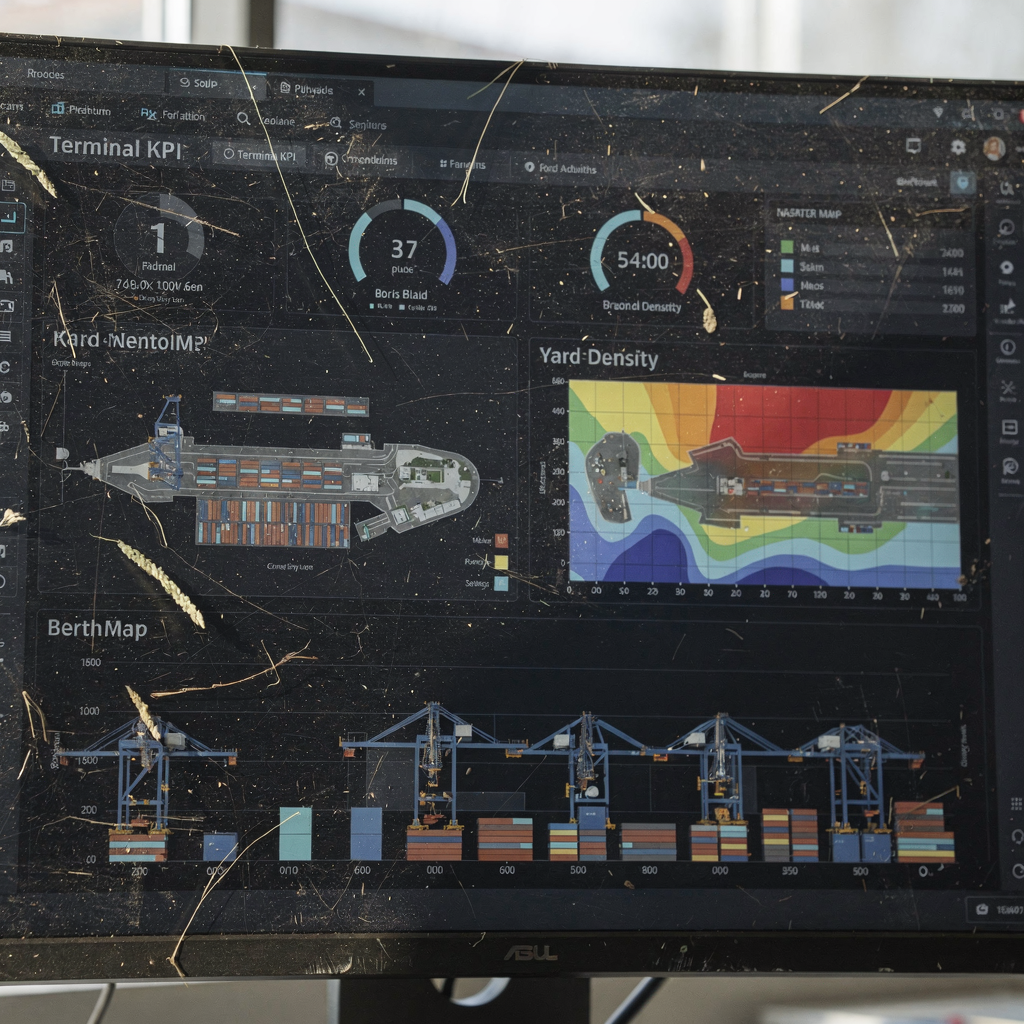

A digital twin merges sensor data, the terminal operating system, and a calibrated simulation to form a live, testable replica. As a result, planners can run multiple scenarios and receive visual feedback in near real-time. Also, the digital twin serves as a decision support layer that highlights KPI trade-offs. For example, it can show how a change to quay crane sequencing affects yard congestion and driving distances. This capability helps to minimize rehandles and reduce operating costs.

Dashboards in a digital twin present clear metrics. For example, berth occupancy, quay crane productivity, container yard density, truck turn times, and idle time and demurrage all appear as widgets. In addition, planners can use drill-downs to inspect moves per hour and per-operator performance. A digital twin supports both planning and disruption response by offering predictive alerts and scenario playbooks. For terminals with a high level of automation, real-time telemetry helps the twin act as a control plane for coordinated moves.

Case evidence shows the value of digital readiness. A Vietnamese terminal study reported a 12% increase in operational accuracy and a 9% reduction in delays for terminals with higher digital readiness scores (study on digital readiness). Also, digital twin research highlights sustainability: simulation-based approaches can deliver carbon emission reductions of about 15–25% when green strategies are modeled and applied (“Simulation-based research provides a robust framework”). The twin becomes a platform for continuous improvement and decision support.

For integration, ensure the twin connects to TOS, IoT sensors, and port community systems. Also, check that the system supports APIs and EDI messaging to capture arrival notices. Loadmaster.ai’s agents train inside a sandbox digital twin and then act against explainable KPIs, which allows closed-loop reinforcement learning without historic bias. The result is a safer rollout and measurable gains in quay productivity, fewer rehandles, and more stable performance across shifts.

Port and Terminal Layout Optimization Strategies

Layout matters. A good terminal layout reduces driving distance, avoids yard congestion, and supports quicker berth turnaround. First, test yard layout designs and quay crane positions with a container yard model. Next, experiment with different stacking rules, block allocation, and feeder lanes. These tests let planners find the most efficient terminal layout for their vessel mix and cargo types. Also, planners can compare single-deep and double-deep stacks to balance storage density and speed.

What-if scenarios let teams test equipment re-allocation and berthing schedules before changes go live. For example, reallocating quay cranes across berths may reduce crane idle time. In addition, altering gate shift patterns can cut truck dwell time. Simulation model runs can quantify such choices and reveal trade-offs in handling systems. The process is particularly useful for a container port planning new investments or for a new terminal that must optimize the placement of quay cranes and RTGs.

Sustainability is part of layout strategy. Simulation provides a powerful tool to measure emissions and energy use from different yard configurations. Indeed, research shows that greener layouts and operational policies can cut carbon emissions by up to 25% when combined with energy-efficient equipment and smarter scheduling (digital twin for sustainability). Also, small layout changes that minimize travel routes reduce fuel consumption and improve quay crane productivity. Planners should test various conditions, such as peak-load and low-demand windows, to ensure robustness.

Finally, include stakeholder views in layout trials. Port authorities, shipping lines, and terminal operators benefit when a tool for port and terminal planning simulates coordinated moves. Simulation and emulation let everyone try multiple scenarios without risk. This risk-free environment promotes consensus and smoother implementation when physical changes are approved.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Throughput Optimization via What-if Simulation

Measuring baseline throughput is step one. Then, run peak-load simulations to learn how the system behaves under stress. For example, simulate container yard saturation, late vessel arrivals, or sudden gate surges. Also, apply optimization methods such as genetic algorithms and heuristics to find improvements. These methods can reassign tasks so equipment and crews work more effectively.

Simulation is a powerful tool for optimizing quay sequences and truck dispatch. For some terminals, optimizing container flow reduced handling time by up to 20% (Arena simulation results). Also, simulation provides visual feedback that helps planners reduce bottle-necking and address underused assets. Use the model to balance crane shifts, minimize travel paths, and protect future stow plans.

Quantitative results show gains in resource utilisation and throughput. For example, simulation modeling helped teams improve allocation efficiency by 10–30% in investment planning exercises (Simulation for Ports). In addition, ports can reduce idle time and demurrage by testing dispatch rules and gate handling alternatives. The combination of tactical scheduling and strategic optimization reduces operating costs and improves system performance.

Loadmaster.ai uses reinforcement learning agents to search policy space and achieve multi-objective optimization. The agents work with a digital twin to optimize crane sequences, stack placement, and job dispatch. This tool to help planners runs millions of simulated decisions, which creates robust policies ready for live deployment. As a result, terminals see fewer rehandles, shorter driving distances, and more stable productivity across shifts.

Port Simulator Applications for Risk Management and Investment Planning

A port simulator supports risk mitigation and investment planning by letting planners stress test scenarios. For example, simulate disruption events such as severe weather, labour strikes, or supply chain shocks. Also, test disruption response playbooks to see which contingency reduces waiting times and protects berth schedules. In a simulated environment, teams can trial alternate dispatch rules and resource re-allocation without harming live operations.

Investment planning requires balancing infrastructure cost against capacity growth. Simulation provides a platform to run multiple scenarios to estimate ROI. For instance, adding quay cranes or RTGs can be compared against improved TOS workflows to find the best capital mix. In addition, simulation helps port authorities estimate long-term benefits, such as reduced operating costs and lower emissions, before committing capital.

Stakeholder collaboration improves when simulation acts as a common language. Shipping lines, freight forwarders, terminal operators, and port authorities can review the same scenarios together. This shared view makes it easier to agree on phasing and to coordinate multimodal transportation links. Also, a port simulator can model intermodal handoffs and bulk cargo flows alongside container flows to show system-wide impacts.

Finally, the simulator supports regulatory and environmental planning. For example, planners can test how new berthing rules affect emissions and noise. In addition, scenario runs can identify system requirements for a planned automation rollout. When combined with a terminal operating system and a digital twin, the simulator becomes a decision support platform for resource allocation, risk-free environment testing, and long-term capacity planning. For more on capacity scenarios and predictive terminal planning, review predictive-terminal-planning-for-port-operations and container-terminal-equipment-planning-explained for deeper context.

FAQ

What is a what-if simulation for container terminals?

A what-if simulation is a risk-free run of port and terminal scenarios to test alternatives. It models resources, processes, and arrivals to identify potential issues and quantify impacts.

How does a digital twin differ from a traditional simulation?

A digital twin links live telemetry and the terminal operating system to a calibrated model. It provides real-time decision support and lets planners run multiple scenarios with current data.

Which software should I consider for port simulation?

Consider options like AnyLogic and Arena for discrete event and multimethod needs. Also, evaluate Port-TOS integration, scalability, and user-friendly visualization before deciding.

Can simulation reduce carbon emissions at a terminal?

Yes. Studies show simulation-based planning and digital twin strategies can reduce emissions by around 15–25% when sustainable practices are applied (research). Also, layout and scheduling changes cut fuel use and equipment idle time.

How do you validate a simulation model?

Validation compares simulation outputs with historical throughput and equipment data. In addition, run sensitivity tests and adjust parameters until model behavior matches the actual system.

What are common variables in a simulation model for a terminal?

Common variables include quay crane schedules, container yard stacking rules, truck arrivals, and berth assignments. Also, operator shifts, equipment reliability, and handling systems are often modeled.

Can simulation help with investment planning?

Yes. Port simulators let planners compare capital options and predict returns under various demand scenarios. Also, they help port authorities balance cost, capacity, and risk.

How does Loadmaster.ai use simulation?

Loadmaster.ai builds a sandbox digital twin and trains RL agents to optimize quay, yard, and dispatch policies. The approach produces policies that improve consistency and reduce rehandles without needing historical data.

Is simulation useful for small terminals?

Absolutely. Even small terminals benefit from discrete event runs that identify bottlenecks and improve truck turn times. Also, scaled simulation tools can support phased automation and modest investments.

How often should a terminal run simulation studies?

Run basic scenario checks monthly and full validation after major layout or process changes. Also, perform stress tests before peak seasons and before deploying new automation or a TOS upgrade.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.